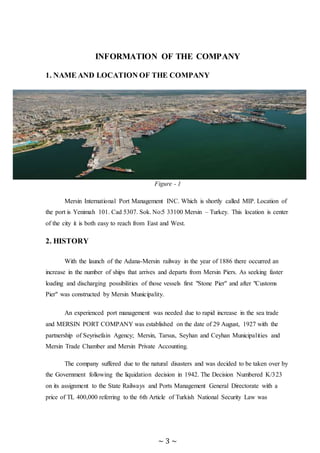

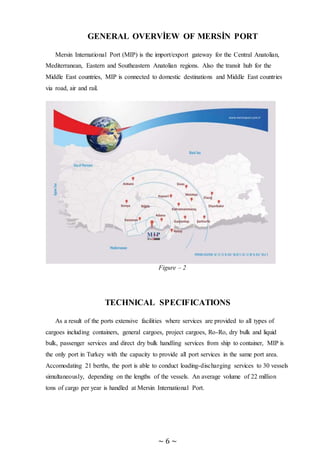

Mersin International Port (MIP) has been operating since 1927 and took over management in 2007. It serves a large hinterland in Turkey and neighboring countries. MIP has 21 berths that can accommodate 30 vessels simultaneously. It handles an average of 22 million tons of cargo annually through services like containers, dry and liquid bulk, general cargo, and roll-on roll-off. MIP aims to be an important transit hub and has the facilities and equipment to provide all port services in a single location.