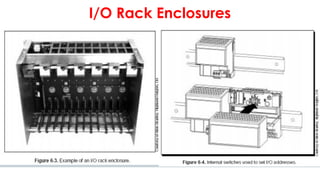

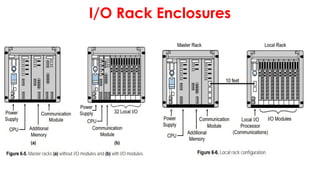

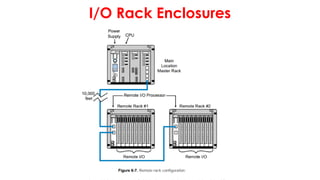

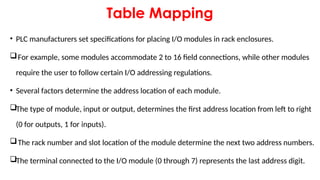

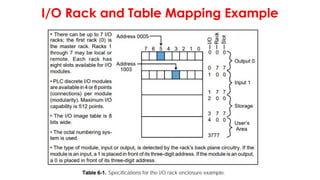

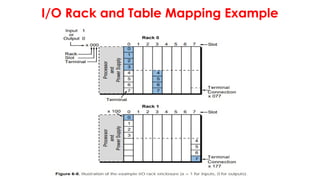

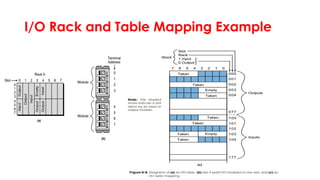

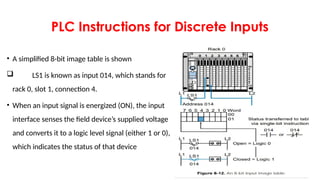

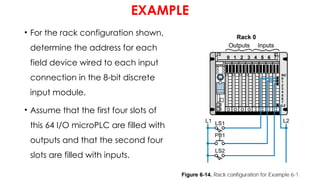

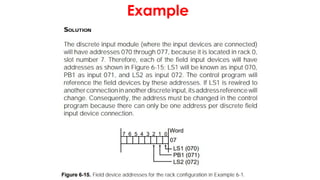

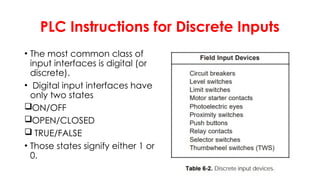

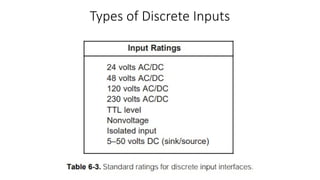

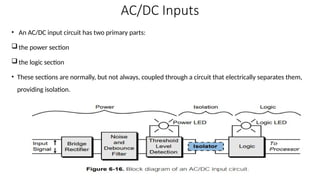

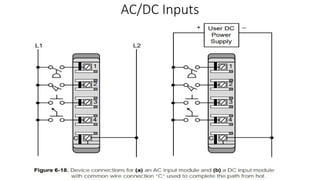

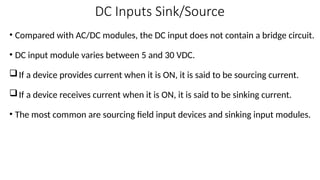

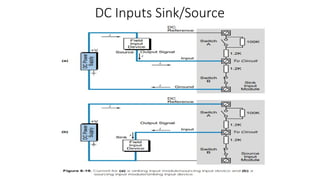

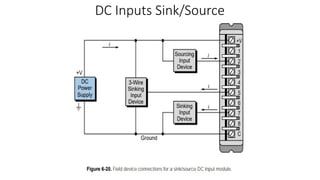

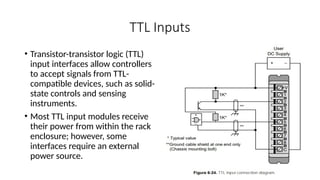

This lecture introduces discrete input/output (I/O) systems used in programmable logic controllers (PLCs), emphasizing their role in connecting CPUs to field devices through digital signals. It covers the organization of I/O modules within rack enclosures, the significance of unique I/O addresses for control programs, and the essential functions of I/O modules such as termination and signal conditioning. Additionally, the lecture discusses various types of discrete inputs, including AC/DC inputs and TTL inputs, and provides practical examples for understanding address mapping for field devices.