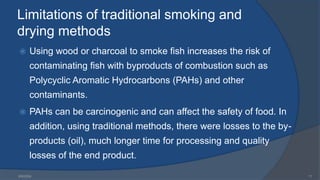

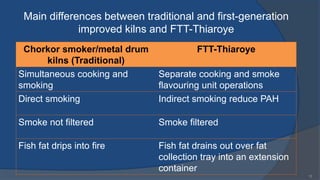

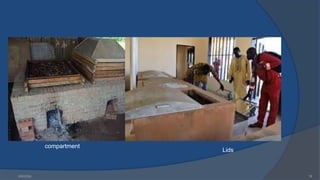

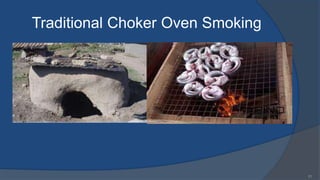

The document discusses fish smoking as a preservation method that combines salting, drying, and heating to extend shelf-life and enhance flavors. It contrasts traditional smoking methods, which carry health risks, with the improved FTT-Thiaroye technique that offers benefits such as higher food safety standards, reduced costs, and better environmental sustainability. Additionally, the document outlines the necessary equipment for implementing the FTT-Thiaroye method, emphasizing its effectiveness in minimizing post-harvest losses.