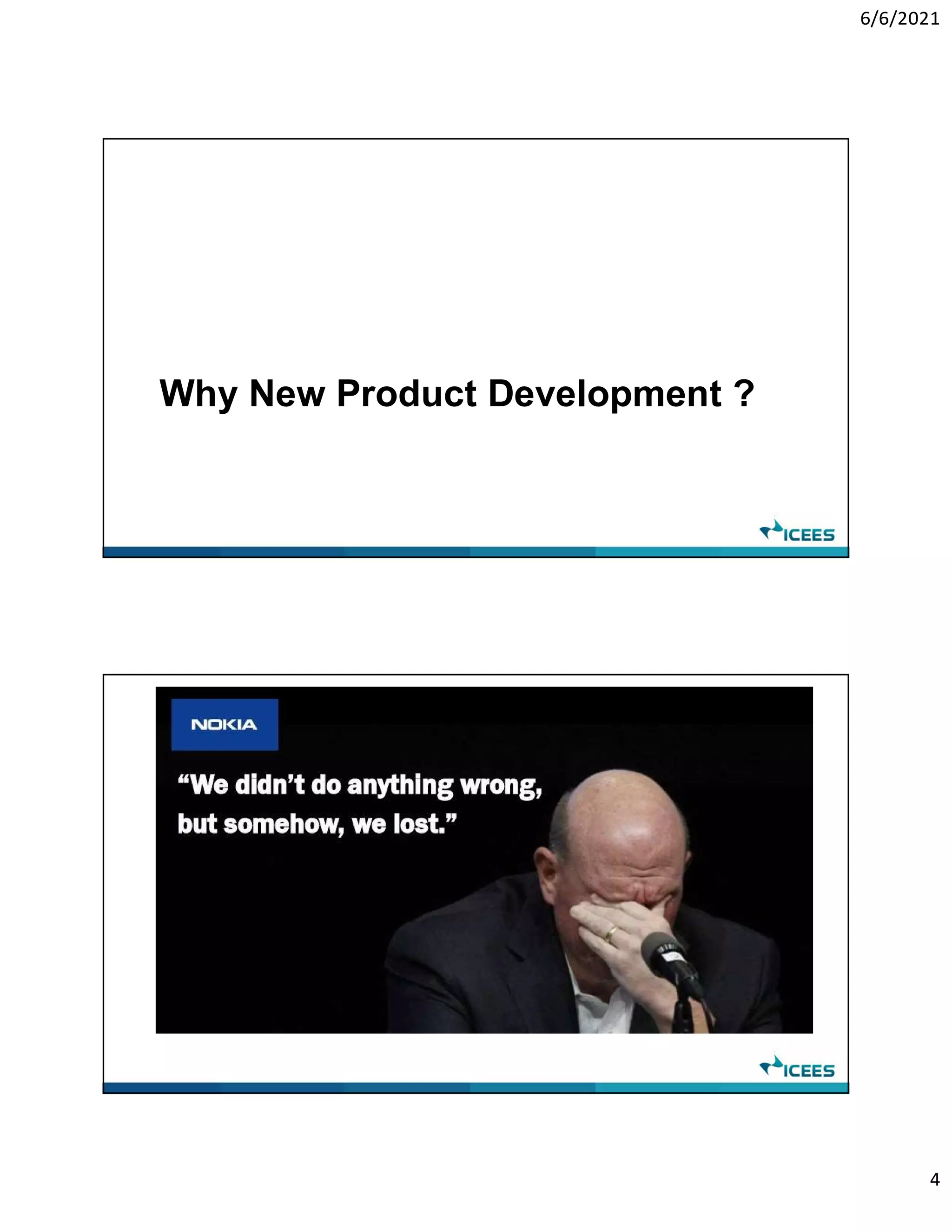

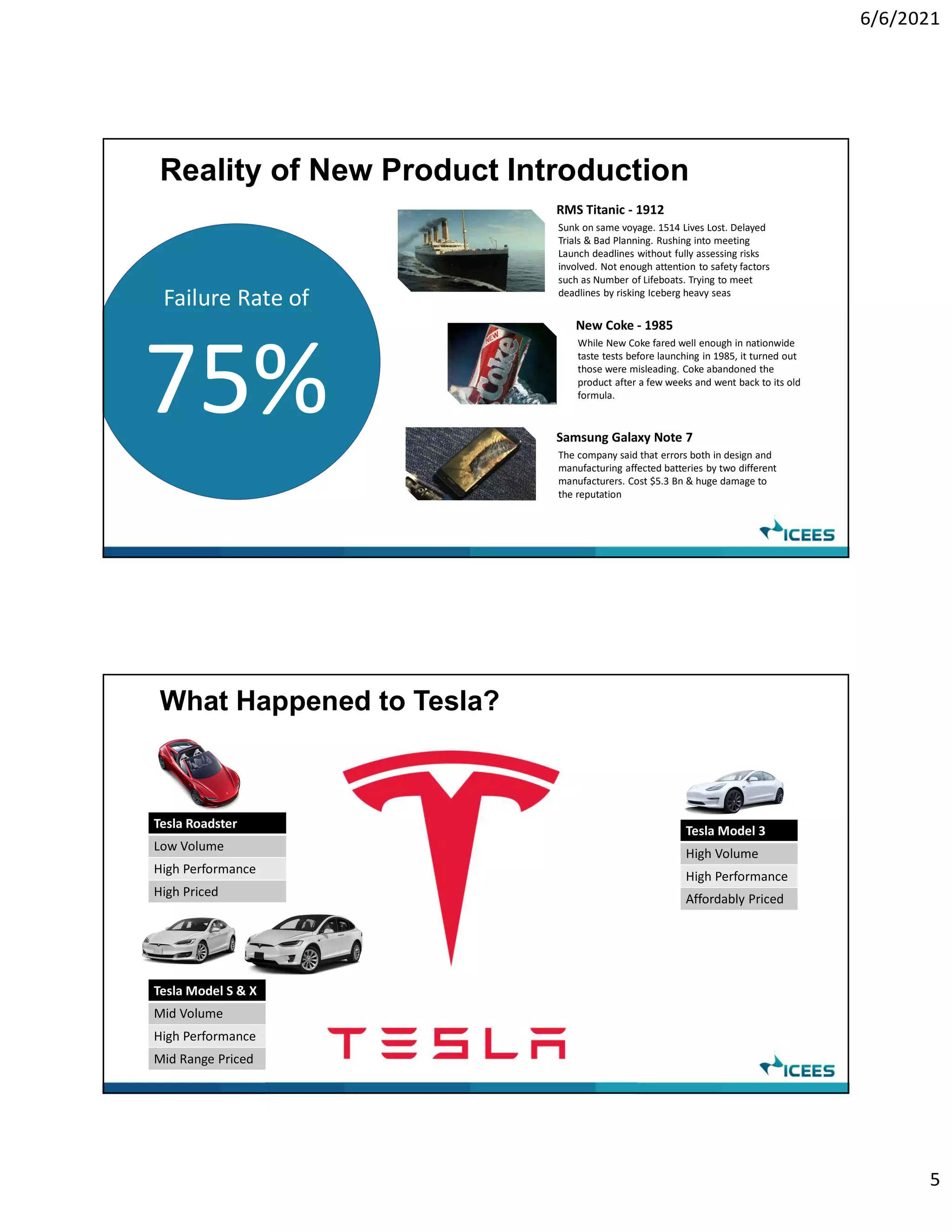

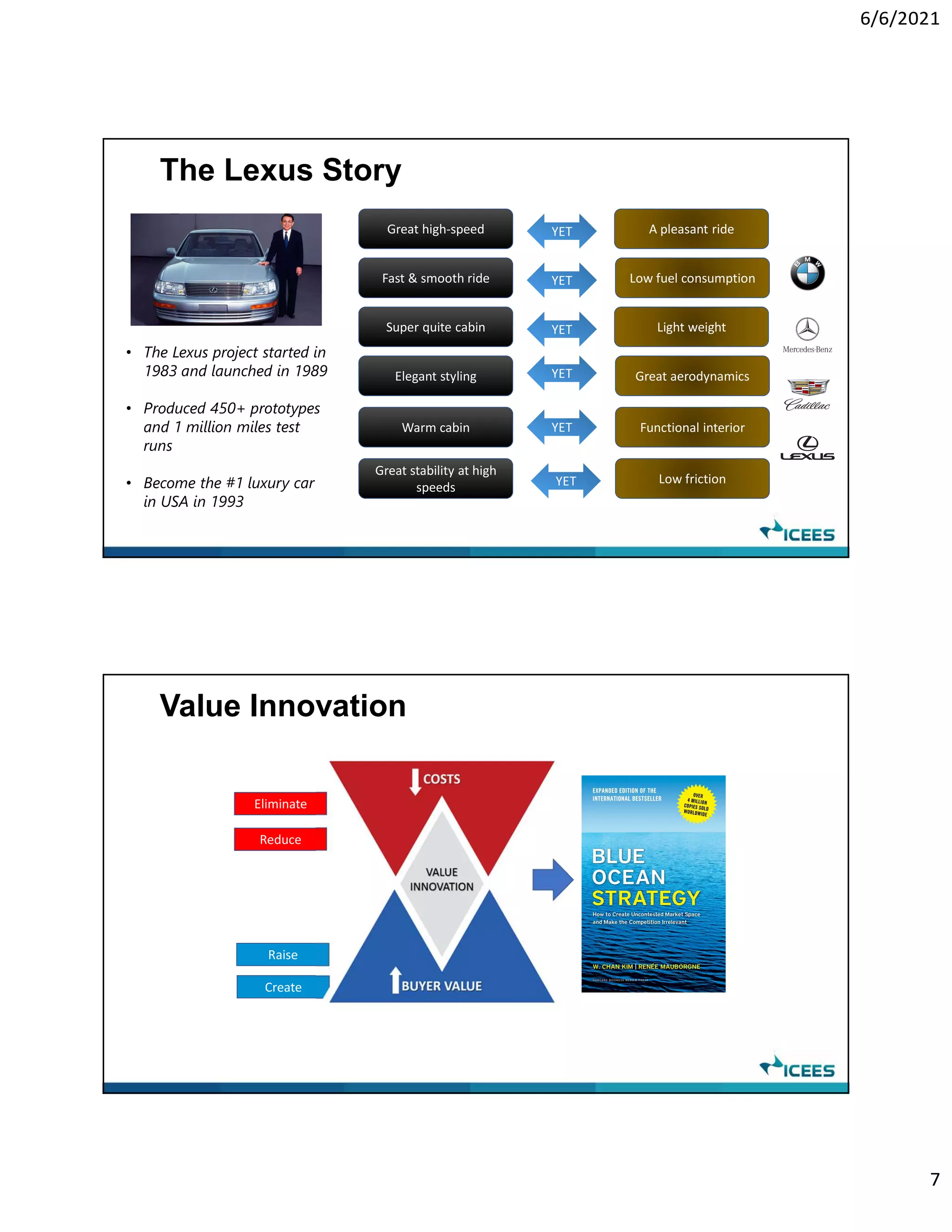

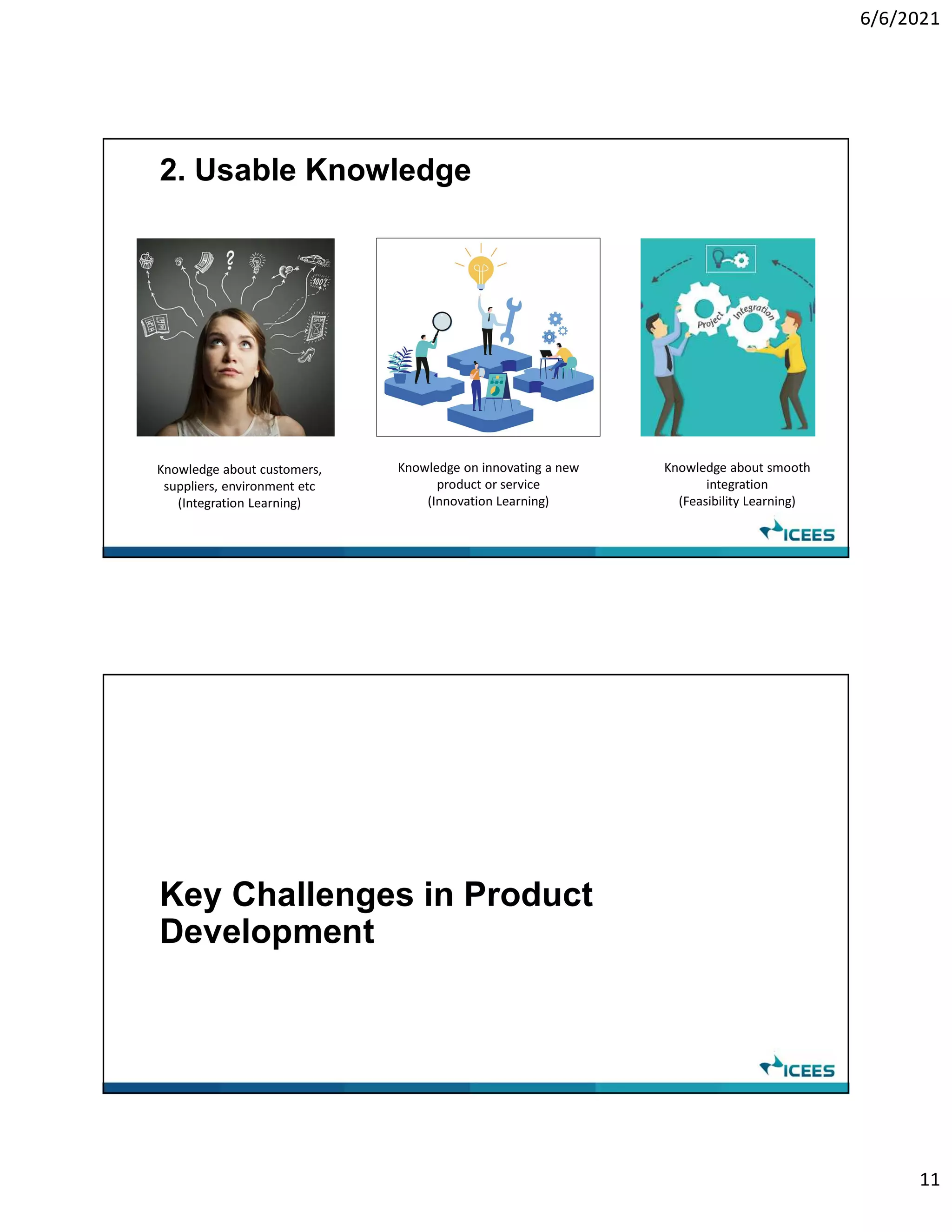

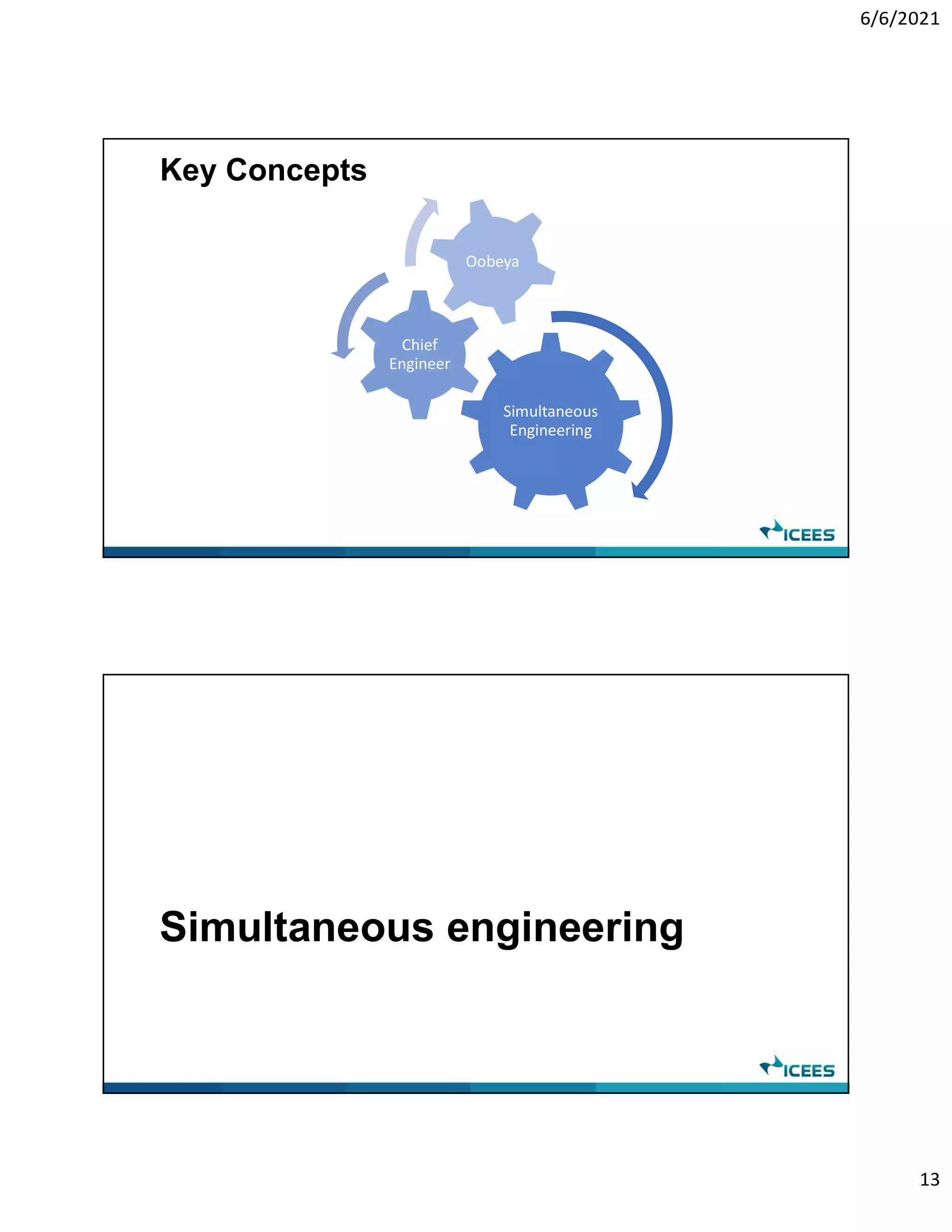

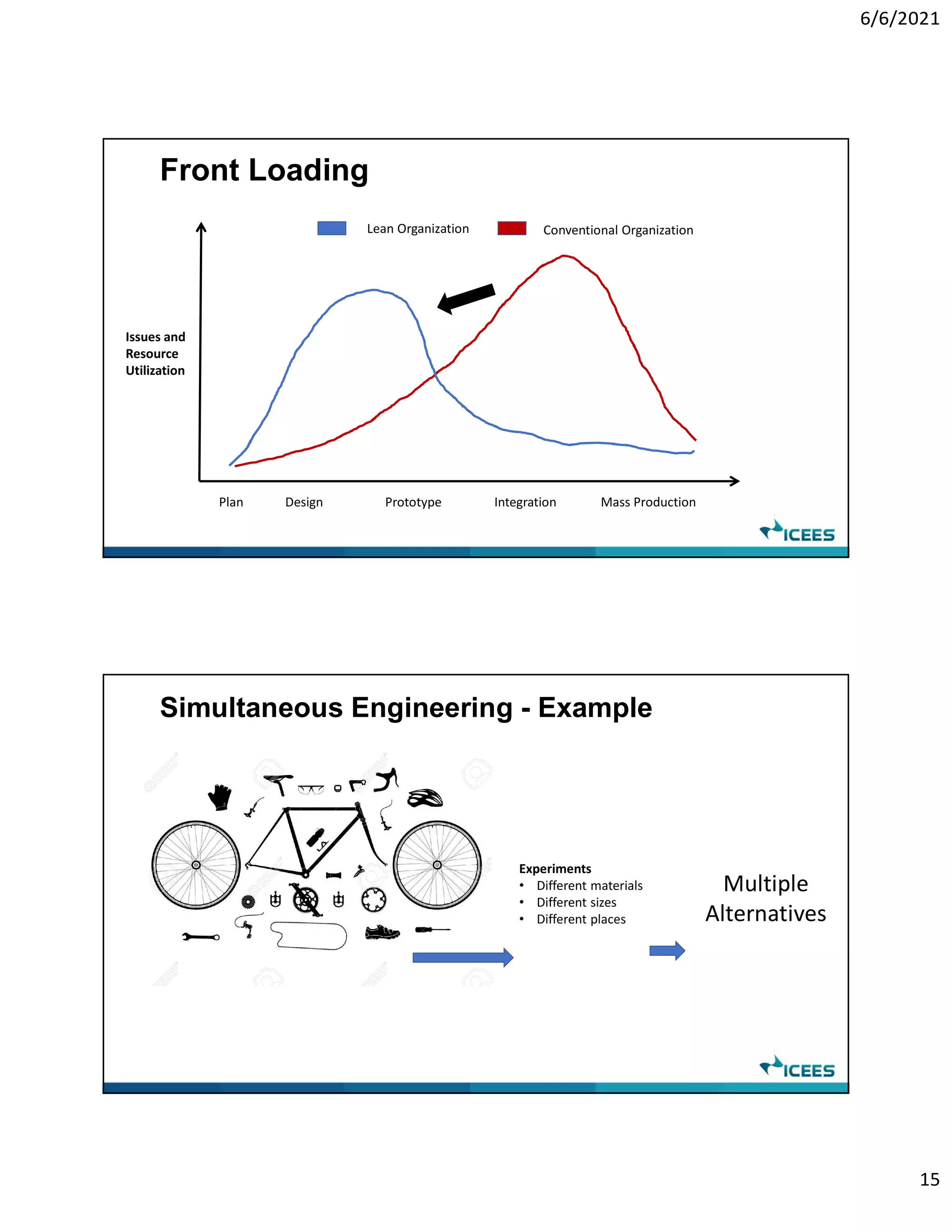

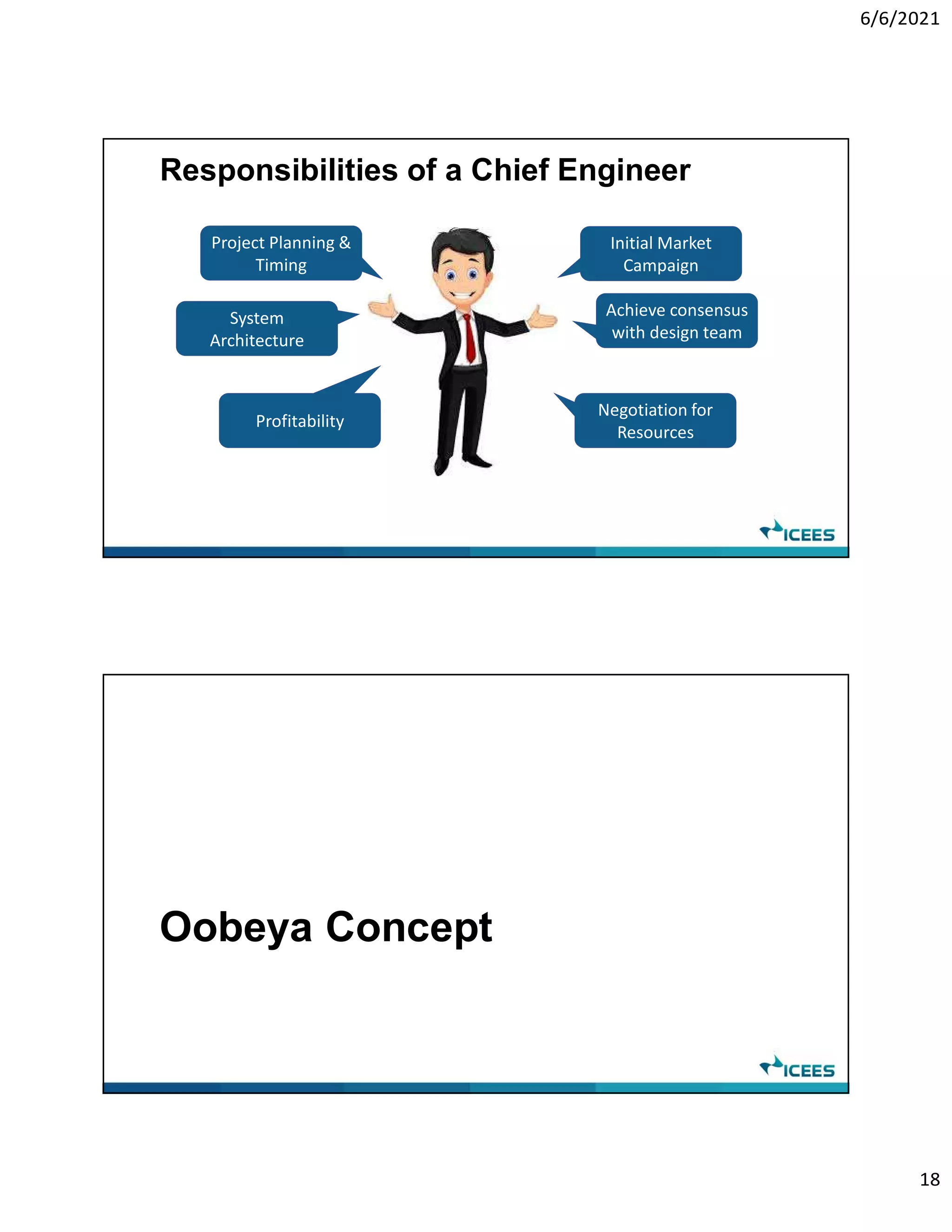

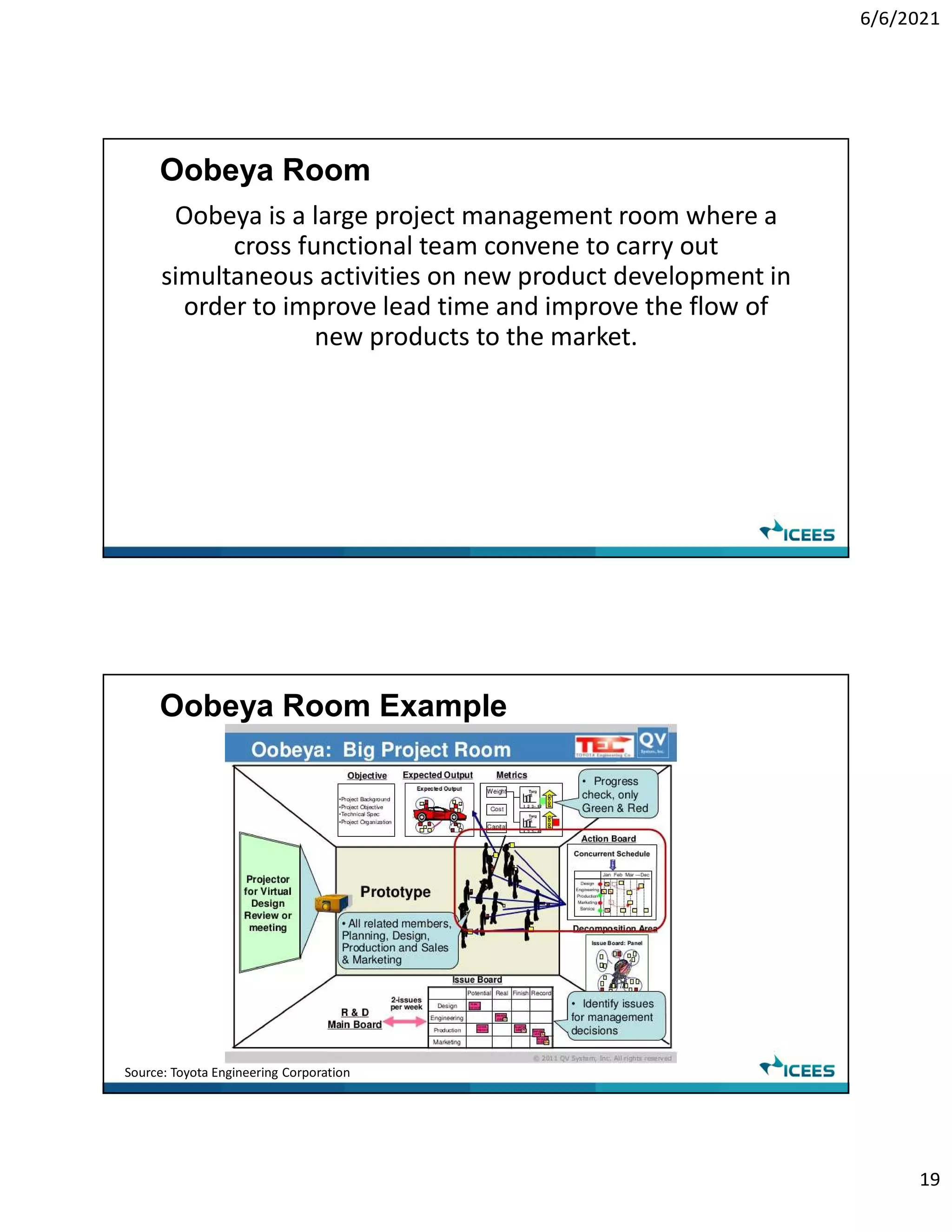

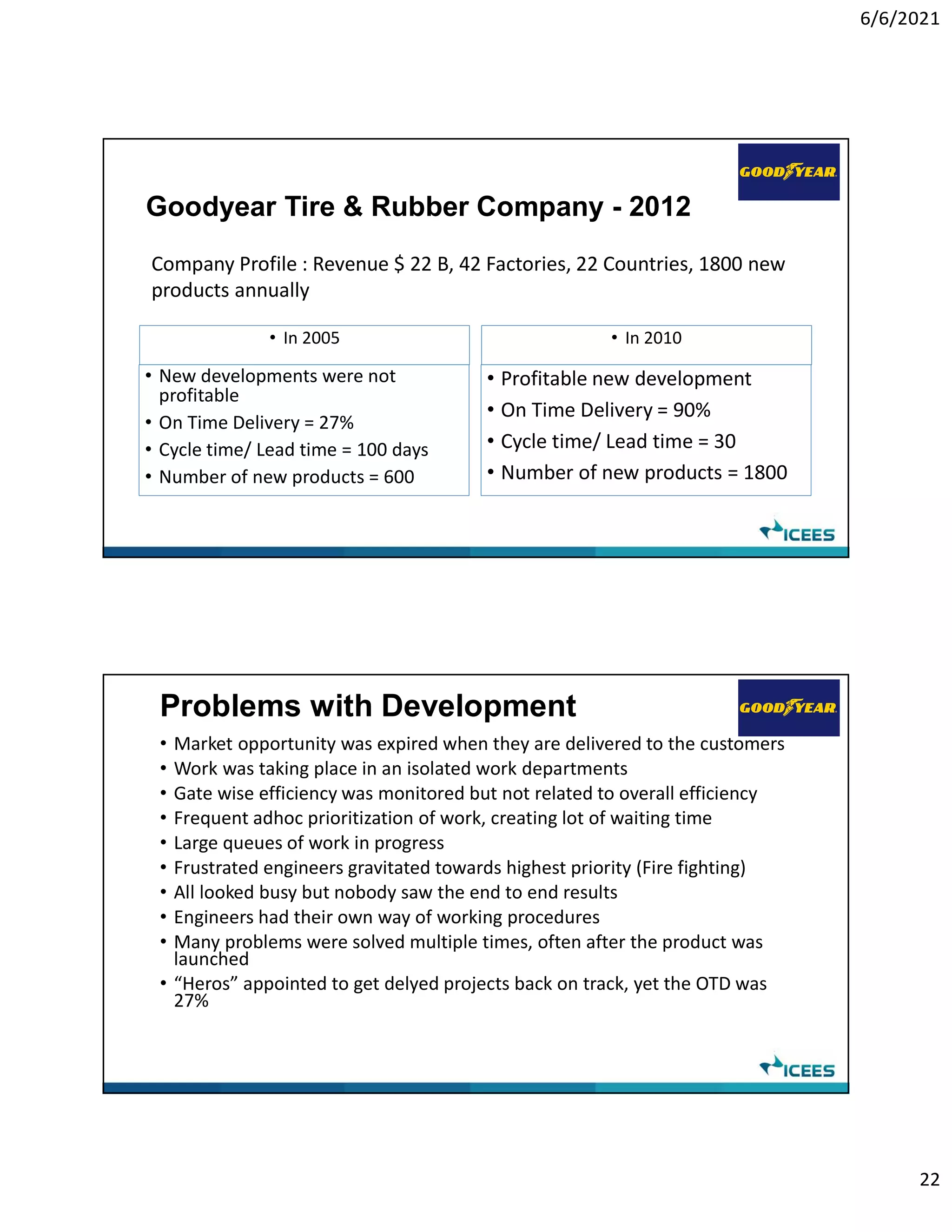

The document outlines a free workshop series focused on value innovation through lean new product and process development, delivered by the Center for Enterprise Excellence Solutions (ICEES). It highlights the importance of effective product development, showcases successful case studies like Lexus and Goodyear, and introduces concepts such as simultaneous engineering and the Oobeya management approach. The workshop aims to improve profitability and efficiency in product development while reducing risks and enhancing team collaboration.