Embed presentation

Download to read offline

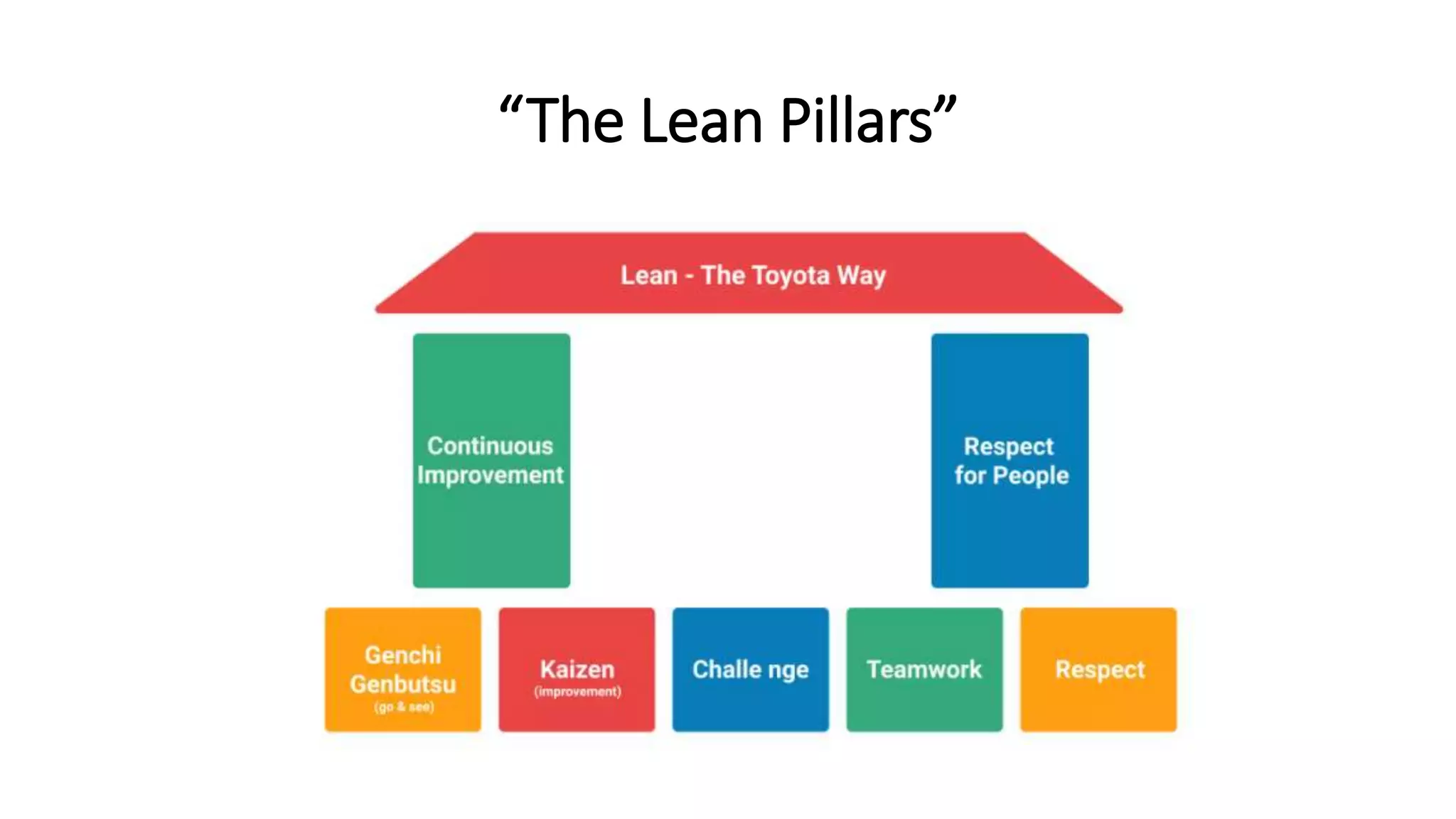

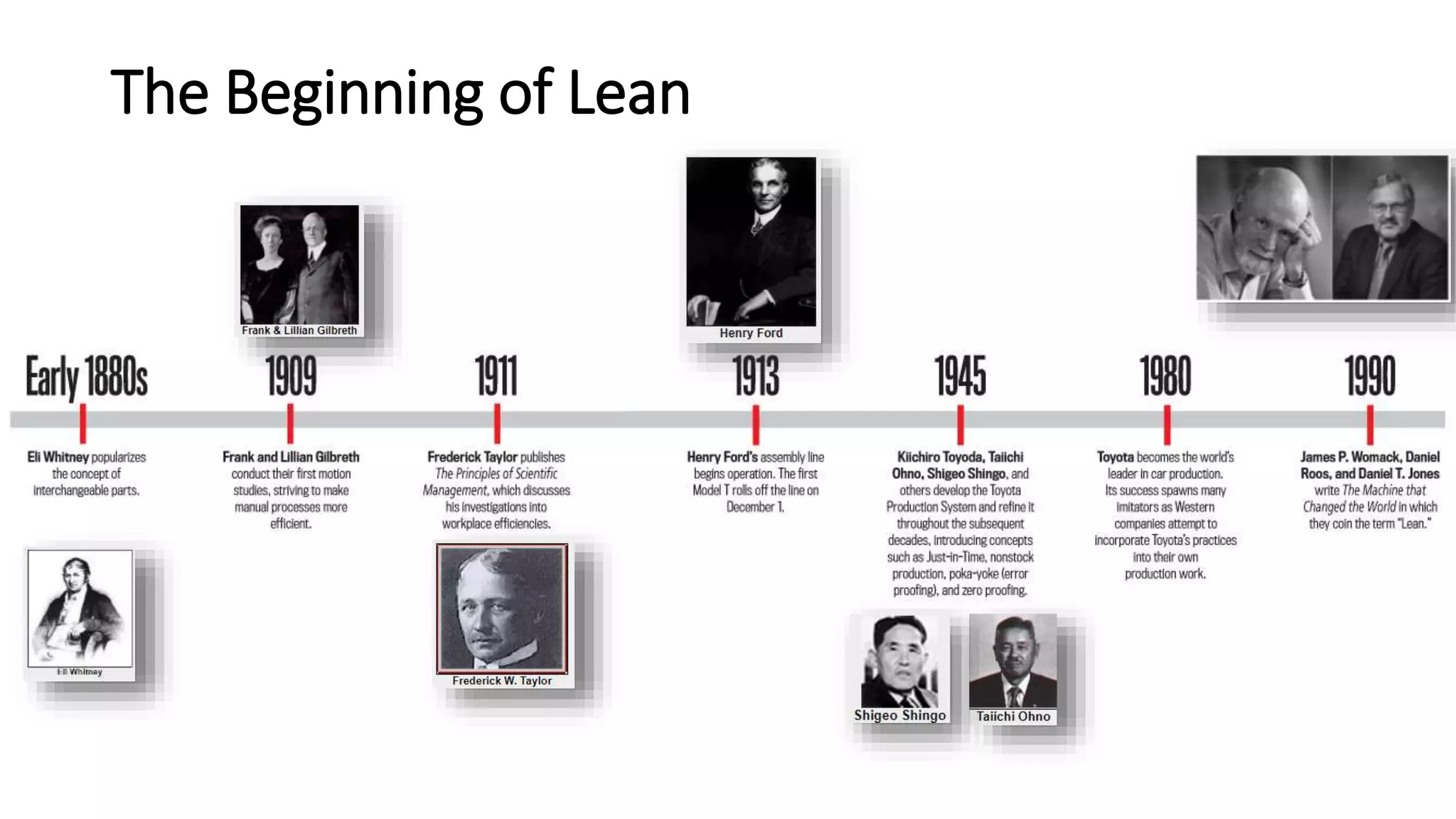

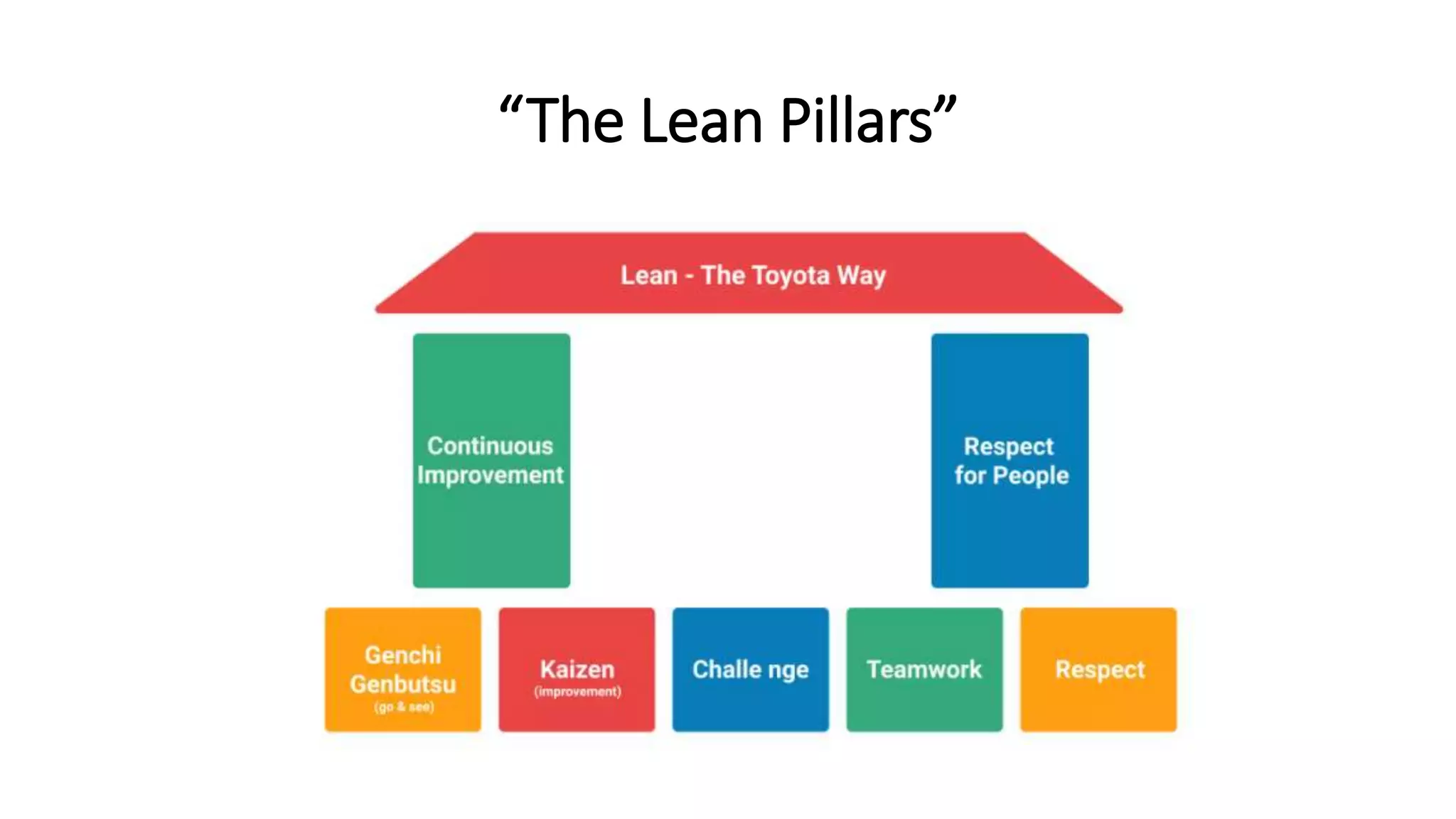

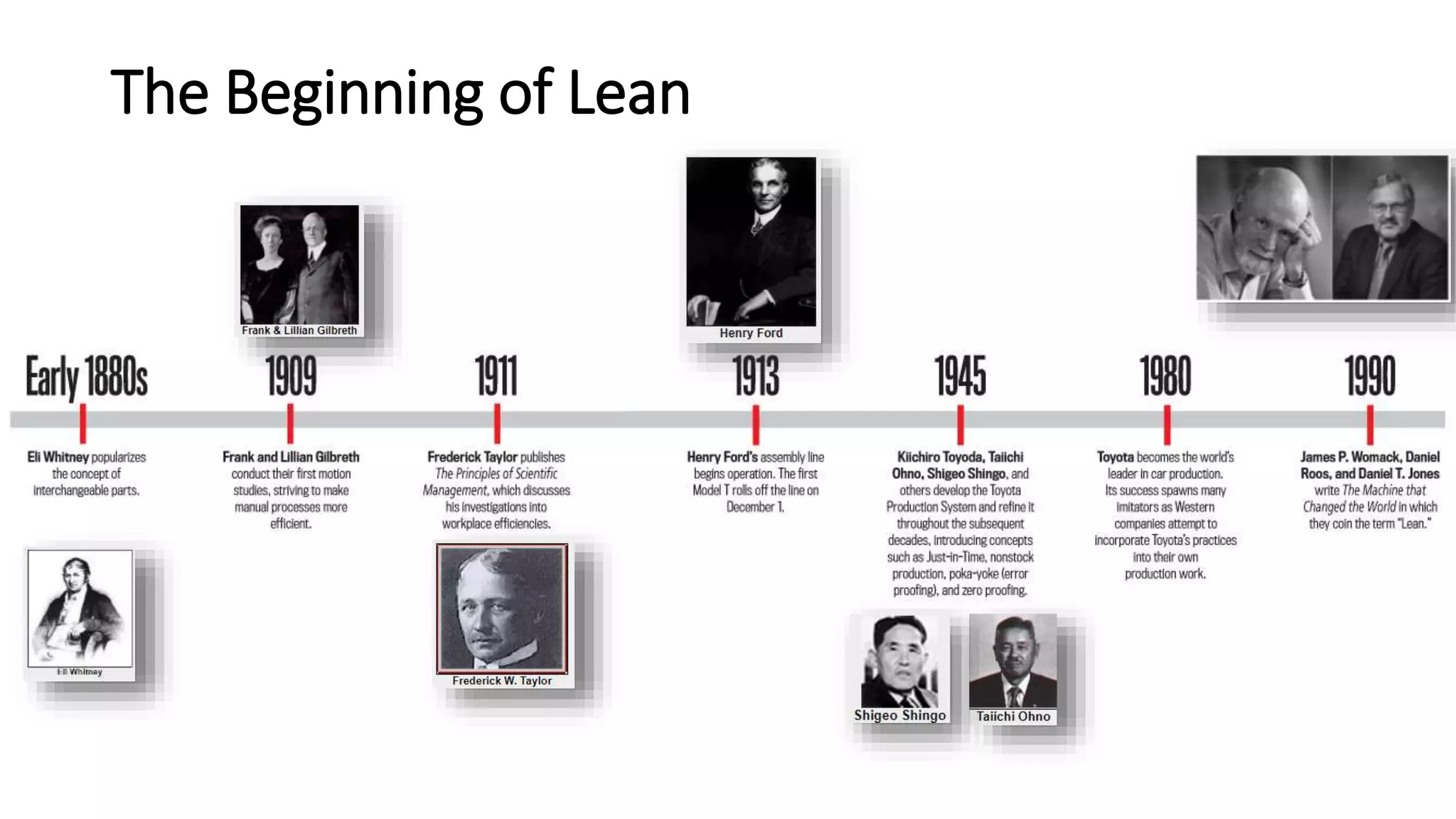

Lean management is a system that continuously improves processes and develops people to bring value with the least amount of resources. It involves employees in improving processes, doing simpler things well, and reducing waste like overproduction, waiting times, unnecessary transport, and defects. Implementing lean management can benefit organizations by increasing focus, productivity, efficiency, and optimizing resources through smarter pull-based processes.