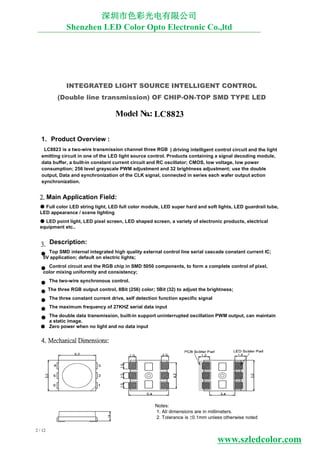

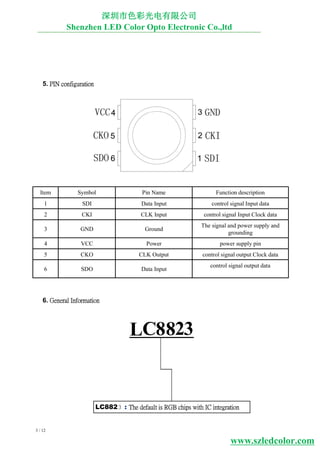

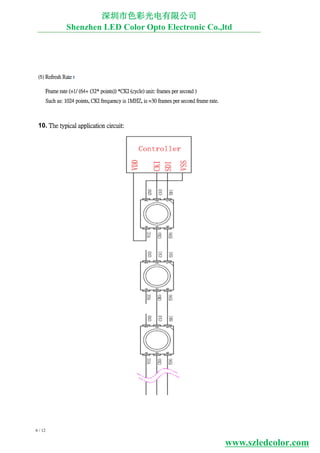

The document provides a detailed overview of the LC8823 LED series, which features a two-wire transmission channel, three RGB output control, and various intelligent control functions. It highlights key specifications such as built-in signal decoding and constant current circuits, making it suitable for various lighting applications including LED string lights and pixel screens. The document also includes technical information about pin configuration and performance metrics.