This document provides specifications for the SK6812 integrated light source intelligent control chip-on-top SMD type LED. Key details include:

- It is a 0.2W top SMD type LED with integrated control circuit and RGB chips.

- Each LED acts as a pixel that can be individually controlled for color and intensity via a digital interface.

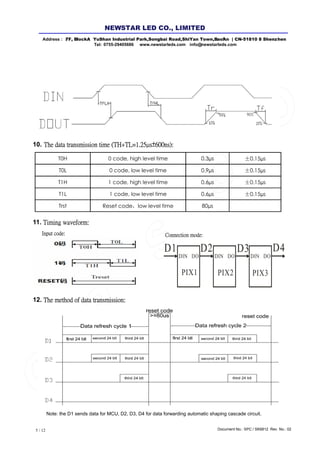

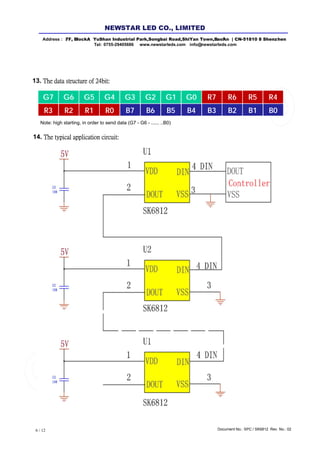

- It uses a 24-bit data protocol for signal transmission between LEDs connected in a chain.

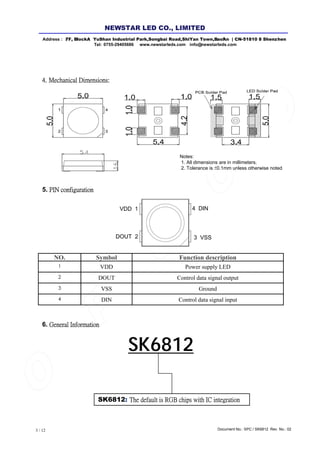

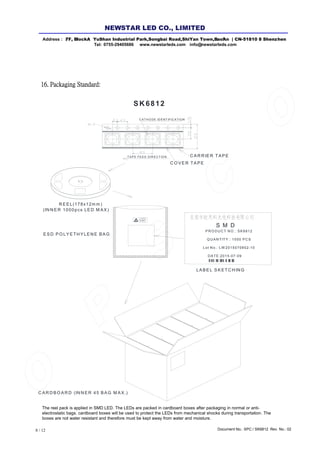

- Specifications include electrical parameters, timing diagrams, data structures, and packaging.