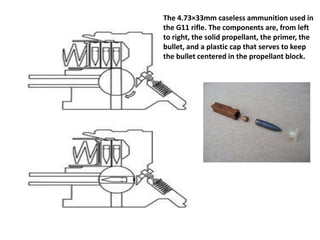

The document discusses recent trends in small arms development. Technological advances have provided more accurate range estimation, enhanced armaments to launch improved munitions, and desired target effects. New munitions include lightweight exploding fragments, multi-projectile technologies, and special purpose projectiles. Fire control systems now feature combinations of day/night sights, electro-optical sights, rangefinders, and thermal imaging. Armaments are being designed with lighter materials, reduced signatures, and modular construction. Bullpup designs provide length savings and improved balance but have disadvantages like difficult magazine changes. The document also examines a caseless 4.73x33mm square ammunition and the G11 rifle that uses it.