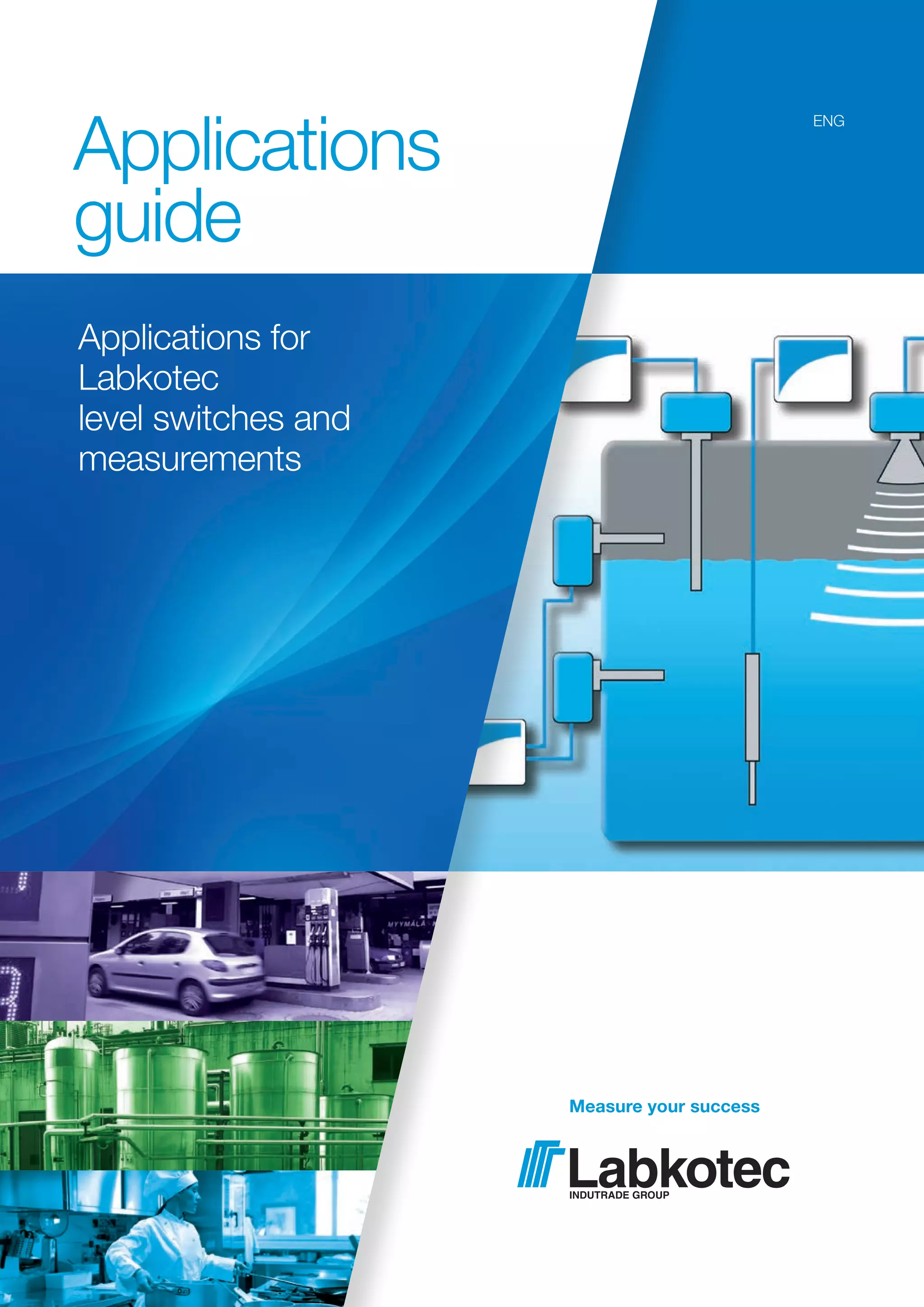

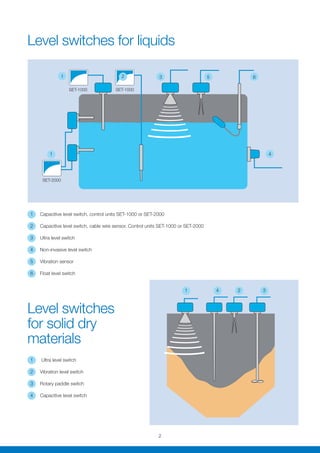

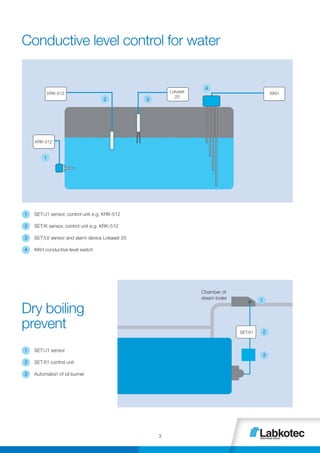

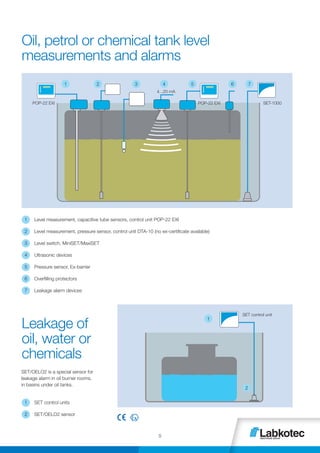

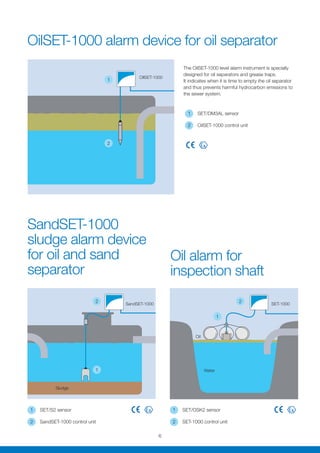

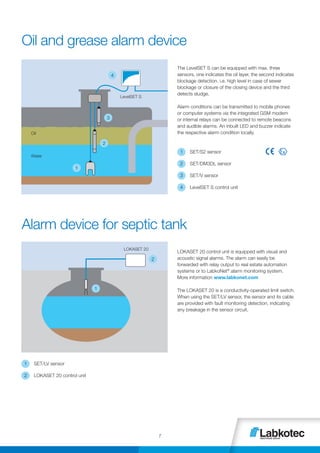

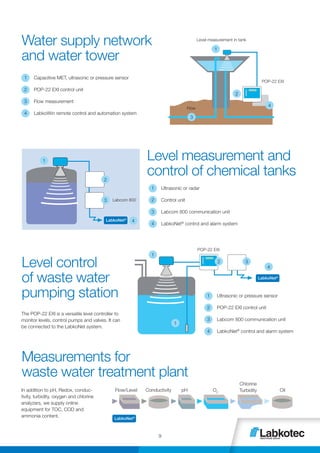

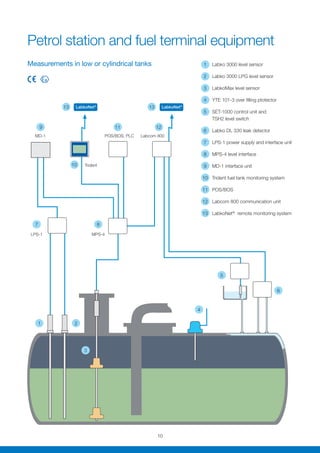

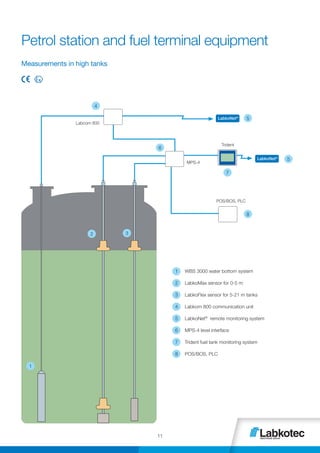

This document provides information on Labkotec's level measurement and control equipment for various applications. It lists different sensor and control unit options for level switches, measurements, alarms and flow measurements in liquids and dry materials in tanks, pipes, channels and more. It also provides details on systems for oil/petrol stations, water networks, and waste water treatment. Labkotec offers a comprehensive portfolio of electronic gauges and detectors along with communication and automation technology.