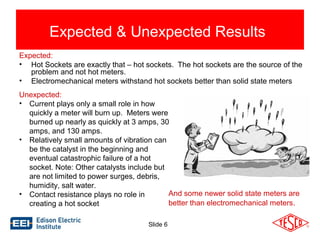

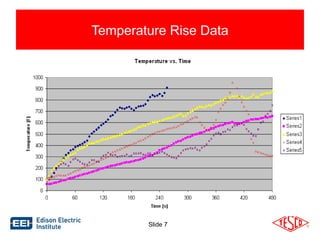

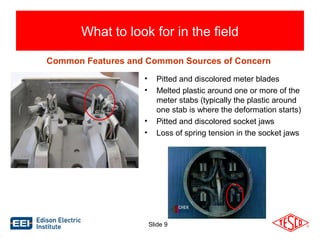

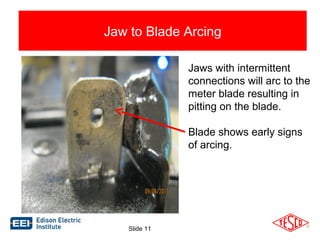

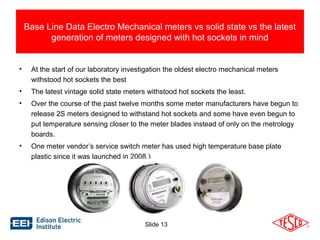

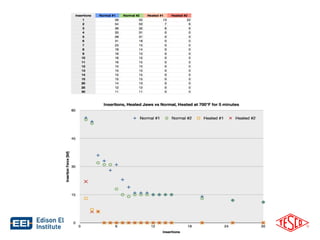

The document discusses the growing issue of hot sockets associated with utility meters, highlighting that the incidence of meter-related fires has increased significantly since the introduction of advanced metering infrastructure (AMI). It outlines the causes and contributing factors for hot sockets, including loss of jaw tension, vibration, and minimal load, and presents findings from lab investigations aimed at understanding and addressing these safety concerns. The presentation emphasizes best practices for inspection and handling of meter installations to ensure customer safety.