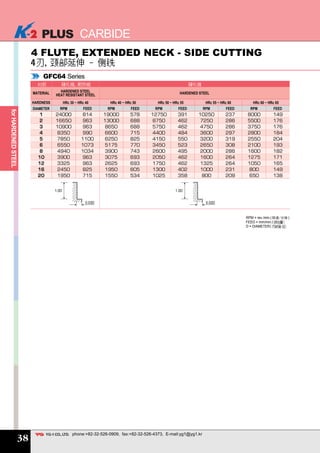

The document provides detailed information about YG-1's multi-purpose carbide end mills for machining various materials including hardened steel, stainless steel, aluminum, and graphite. It outlines the specifications, sizes, and applications of different end mill models, emphasizing their compatibility with high-speed machining and wet/dry cutting conditions. YG-1 aims to maintain its position as a global leader in the market, offering high-quality tools designed for superior performance.