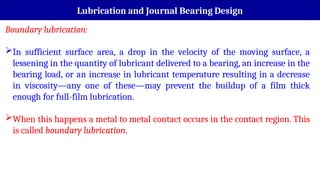

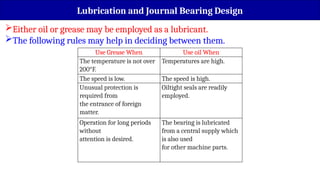

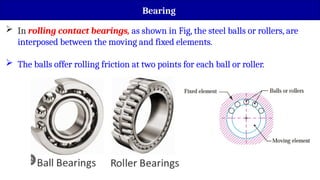

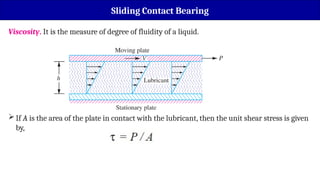

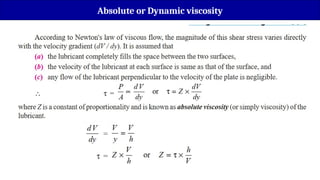

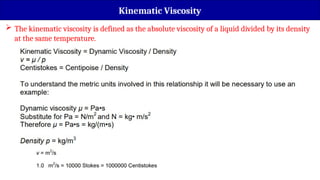

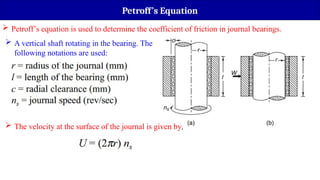

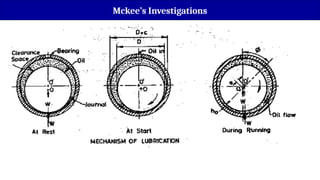

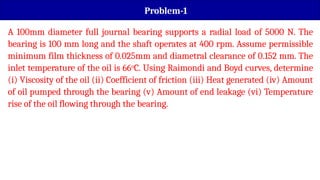

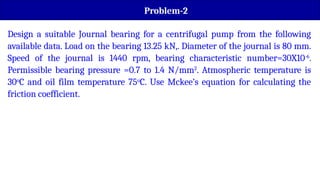

The document discusses the design and types of lubrication systems used in journal bearings, highlighting five lubrication methods: hydrodynamic, hydrostatic, elasto-hydrodynamic, boundary, and solid film lubrication. It explains the functions and characteristics of each lubrication type, as well as guidelines for using oil or grease as lubricants in different conditions. Further, it details the classification of bearings based on load direction and contact nature, and includes calculations for performance metrics such as viscosity and friction coefficients in journal bearings.