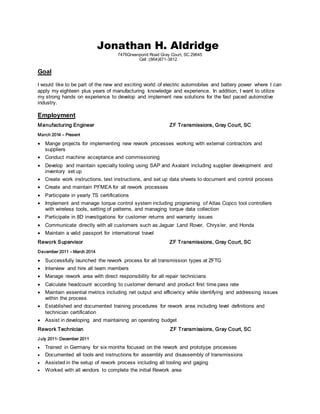

Jonathan Aldridge is seeking a position in the electric vehicle industry where he can apply his 18+ years of manufacturing experience. He currently works as a Manufacturing Engineer at ZF Transmissions, where his responsibilities include managing projects, conducting machine acceptance, developing tooling, and participating in quality investigations. Previously he held supervisory roles overseeing maintenance and rework operations at ZF Transmissions and KS Gleitlager. Aldridge has strong hands-on skills in areas like welding, hydraulics, and pneumatics from over 15 years of experience in maintenance technician roles. He is educated with a high school diploma and trained in SAP, Axalant, lock out tag out procedures, and through experience working in