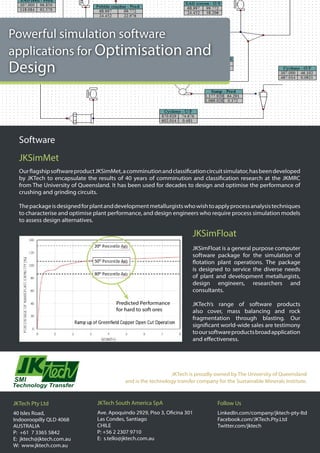

This document discusses specialized testing equipment and software used for analyzing ores and optimizing mineral processing operations. It describes the JK Drop Weight Tester, which conducts the JK Drop Weight (JKDW) and SMC Tests to characterize ore breakage. Over 42,000 tests have been completed across 32 commodities using these standardized industry tests. Additional tests and software described include the JK Bond Ball Mill Test, geometallurgical tests, JKSimMet simulation software for comminution circuits, and JKSimFloat software for flotation plant simulation. JKTech provides these tools and services to help mining companies gain competitive advantages through process analysis and optimization.