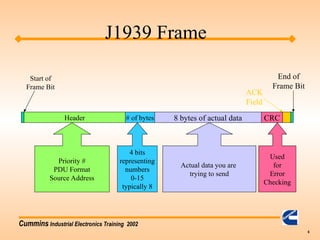

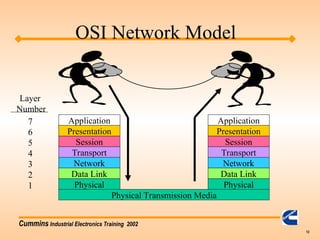

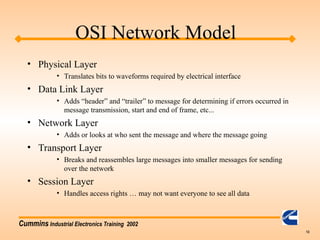

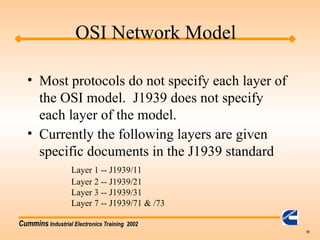

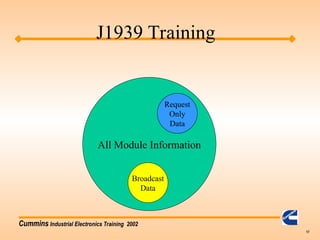

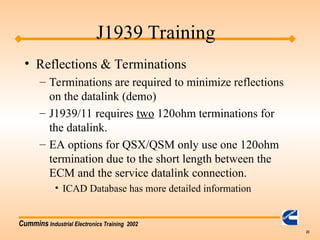

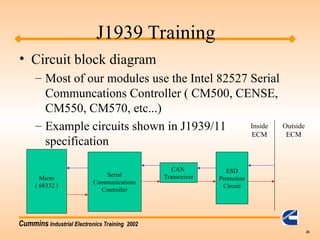

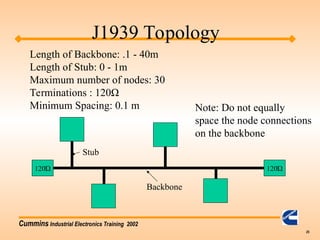

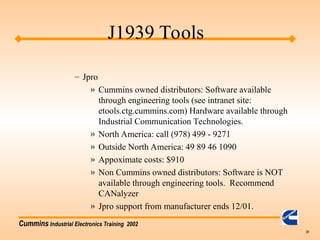

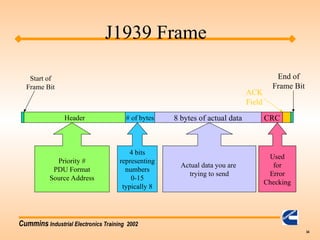

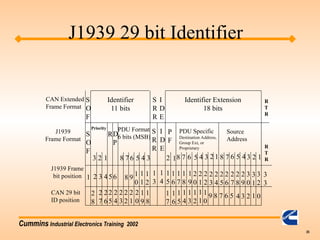

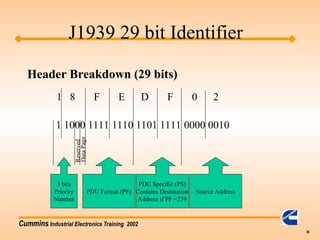

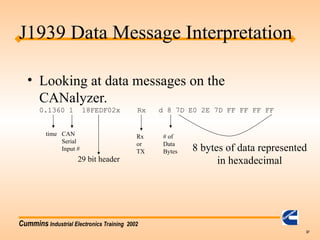

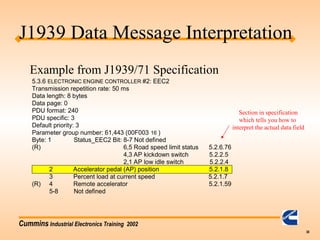

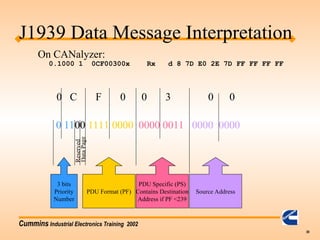

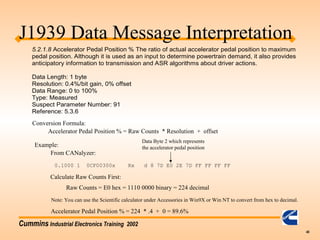

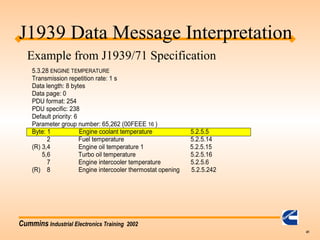

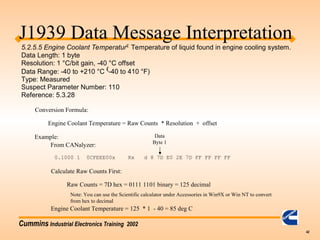

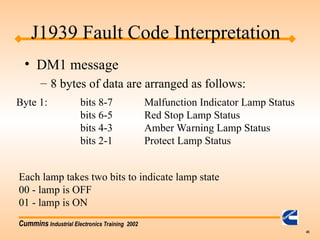

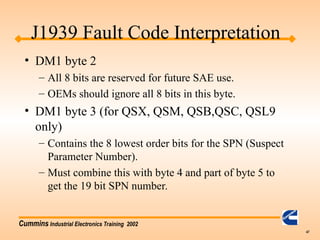

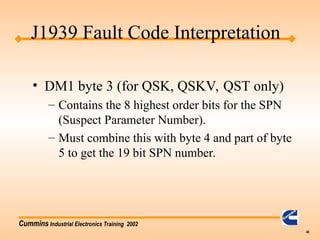

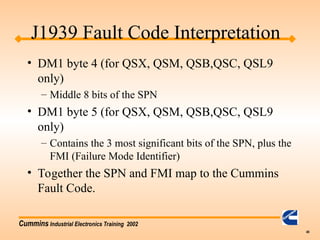

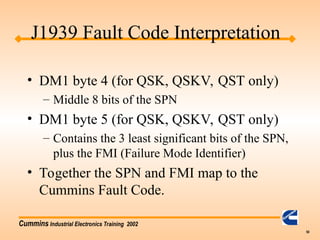

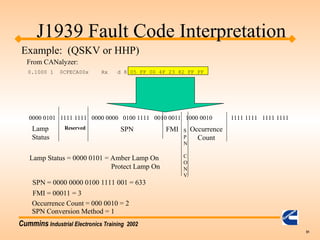

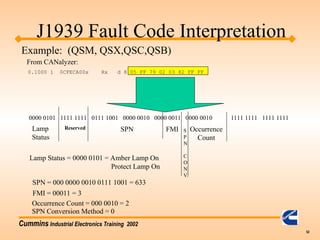

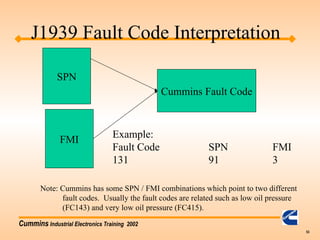

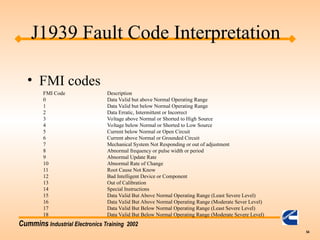

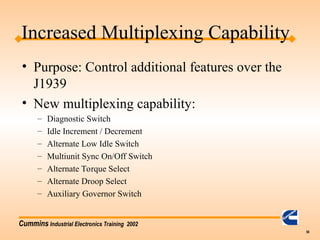

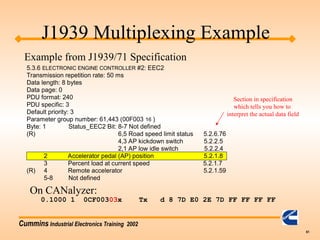

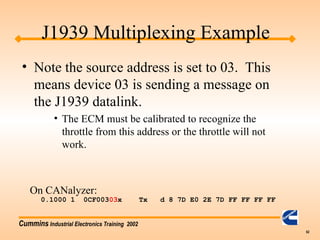

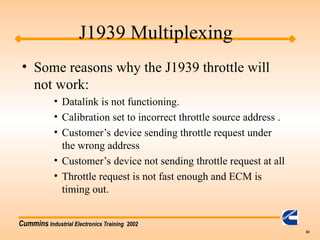

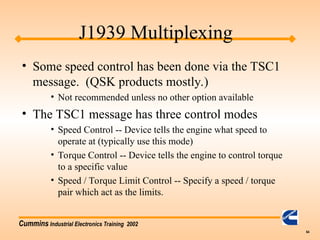

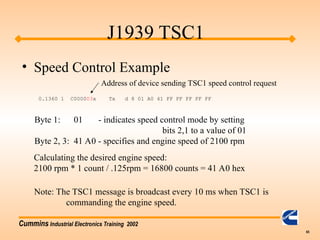

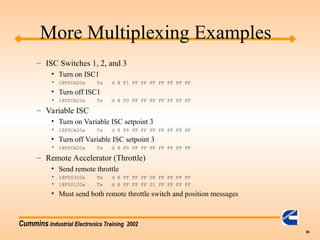

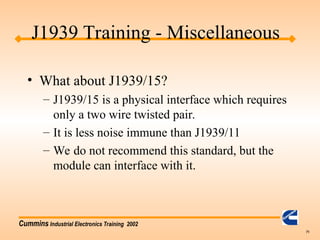

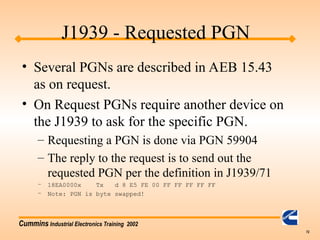

The document details the Cummins Industrial Electronics Training related to J1939 protocol, outlining basic and advanced training topics such as vocabulary, monitoring, control, and message breakdown. It covers essential terms used in J1939 communication, including data frame structure, error detection mechanisms, and the OSI model layers that relate to J1939. Additionally, it discusses tools for monitoring and troubleshooting, along with specific examples of message interpretation for engine parameters.