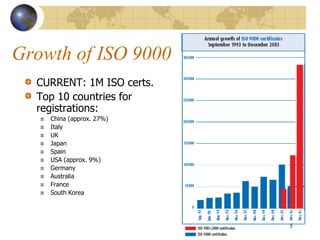

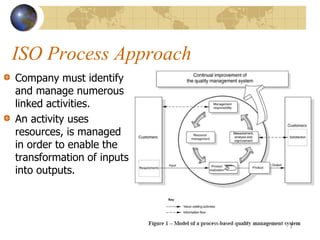

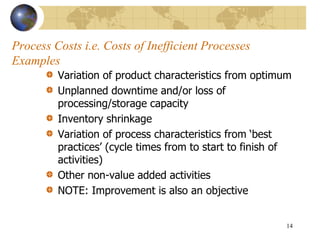

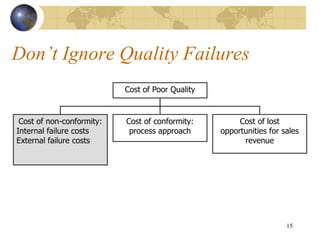

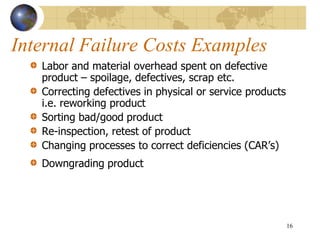

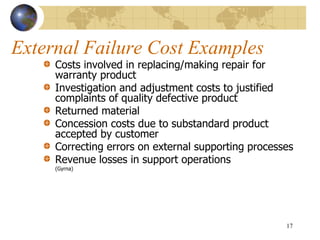

The document discusses Quality Management Systems (QMS) and the ISO 9000 standard, which helps organizations achieve consistency and customer satisfaction through defined processes. It highlights the principles of QMS, costs associated with quality, and the benefits of systematic process management. Additionally, it emphasizes the need for continual improvement and the economic implications of managing both conformance and non-conformance costs.