Iron ore filtration is a critical process in the beneficiation and dewatering of iron ore concentrates. The efficiency of filtration directly impacts moisture content, operational costs, and downstream processing. This study explores the role of a fatty alcohol-based surfactant in improving iron ore filtration by reducing cake moisture, enhancing dewatering efficiency, and optimizing operational performance.

Iron Ore Demand and Production Trends

The global demand for iron ore has remained strong due to rapid industrialization and urbanization, particularly in Asia. However, fluctuating ore grades and stringent environmental regulations pose significant challenges for mining and processing operations. Iron ore fines, often produced in beneficiation plants, require efficient dewatering to be commercially viable.

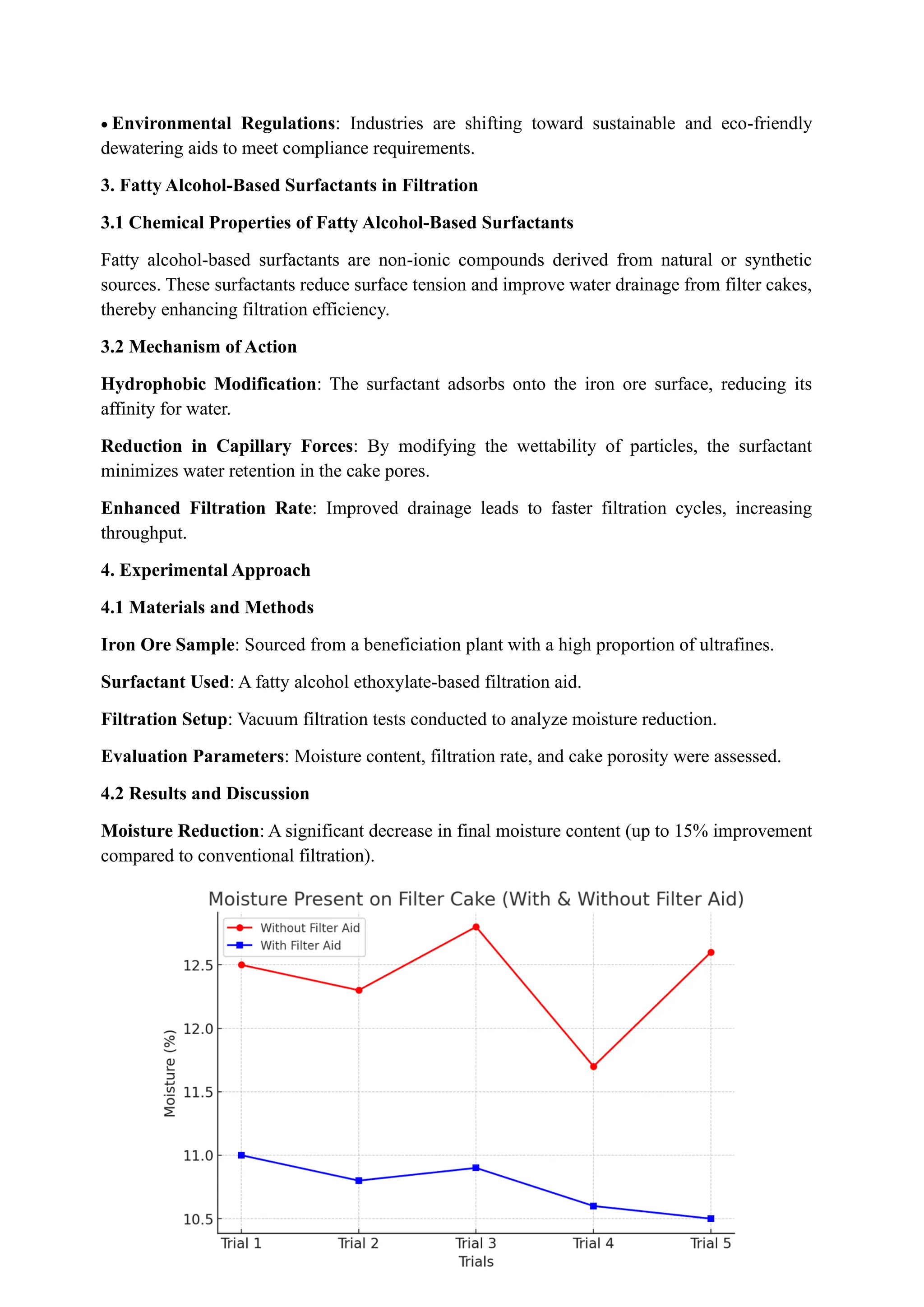

High Moisture Content: Traditional filtration methods often leave high residual moisture, leading to increased handling costs.

Fine Particle Size: The increasing proportion of ultrafine particles in iron ore concentrates makes filtration less efficient.

Operational Bottlenecks: High vacuum and pressure requirements add to energy consumption and maintenance costs.

Environmental Regulations: Industries are shifting toward sustainable and eco-friendly dewatering aids to meet compliance requirements.

Hydrophobic Modification: The surfactant adsorbs onto the iron ore surface, reducing its affinity for water.

Reduction in Capillary Forces: By modifying the wettability of particles, the surfactant minimizes water retention in the cake pores.

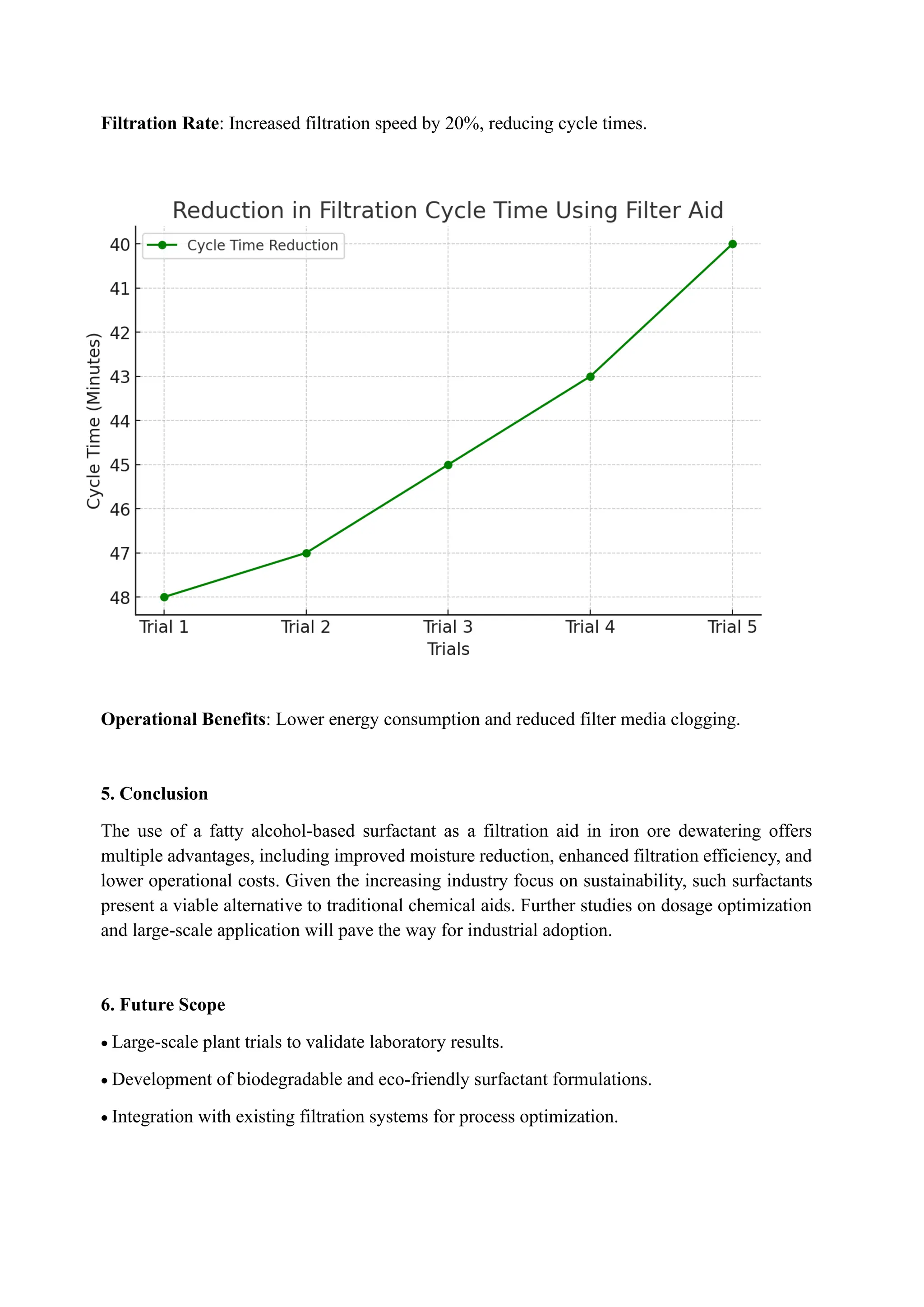

Enhanced Filtration Rate: Improved drainage leads to faster filtration cycles, increasing throughput.

Materials and Methods

Iron Ore Sample: Sourced from a beneficiation plant with a high proportion of ultrafines.

Surfactant Used: A fatty alcohol ethoxylate-based filtration aid.

Filtration Setup: Vacuum filtration tests conducted to analyze moisture reduction.

Evaluation Parameters: Moisture content, filtration rate, and cake porosity were assessed.

Materials and Methods

Iron Ore Sample: Sourced from a beneficiation plant with a high proportion of ultrafines.

Surfactant Used: A fatty alcohol ethoxylate-based filtration aid.

Filtration Setup: Vacuum filtration tests conducted to analyze moisture reduction.

Evaluation Parameters: Moisture content, filtration rate, and cake porosity were assessed.

Materials and Methods

Iron Ore Sample: Sourced from a beneficiation plant with a high proportion of ultrafines.

Surfactant Used: A fatty alcohol ethoxylate-based filtration aid.

Filtration Setup: Vacuum filtration tests conducted to analyze moisture reduction.

Evaluation Parameters: Moisture content, filtration rate, and cake porosity were assessed.

Materials and Methods

Iron Ore Sample: Sourced from a beneficiation plant with a high proportion of ultrafines.