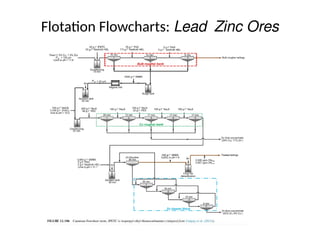

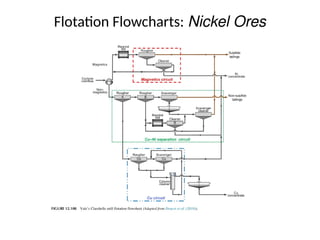

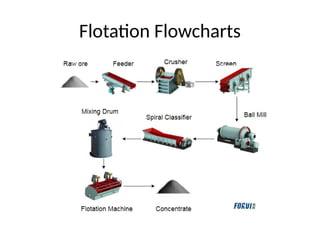

The document provides a comprehensive overview of flotation processes in mineral processing, focusing on copper and coal ores. It discusses the importance of flotation technology, various processing techniques, challenges faced, and case studies of significant operations like Highland Valley and Grasberg. Additionally, it highlights advances in flotation technology, the economic significance of by-product recovery, and the essential considerations for optimizing flotation circuits.