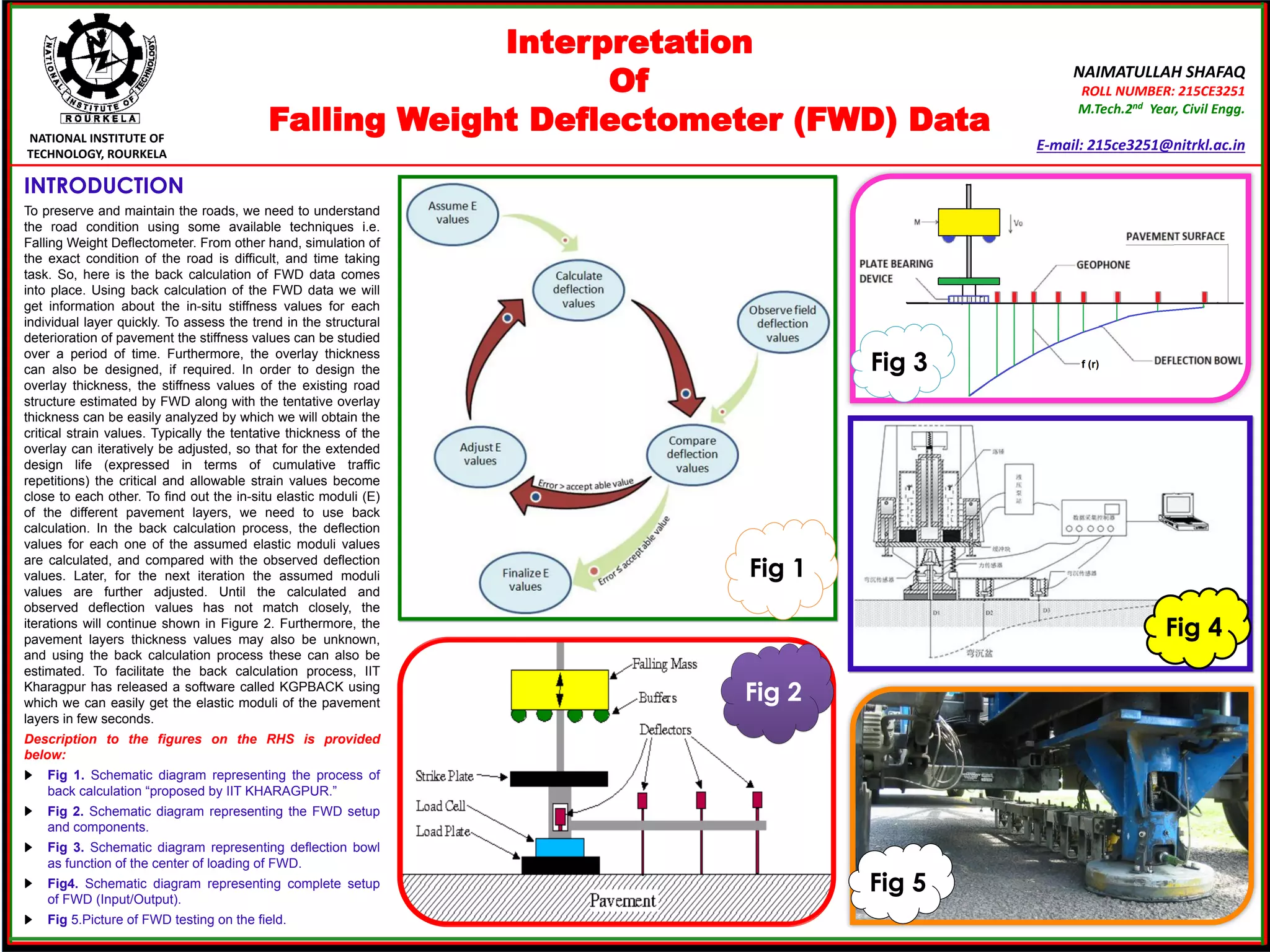

This document discusses the interpretation of falling weight deflectometer (FWD) data through back calculation. Back calculation is used to estimate the in-situ stiffness values of individual pavement layers by comparing calculated and observed deflection values from FWD testing in an iterative process. The software KGPBACK facilitates back calculation and can determine elastic moduli of pavement layers quickly. FWD testing provides deflection data that can be analyzed through back calculation to evaluate pavement condition and design overlay thicknesses.