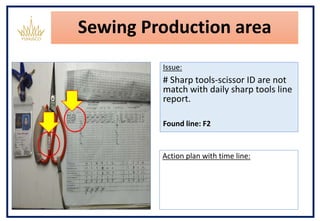

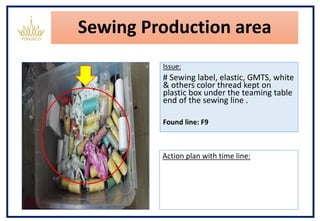

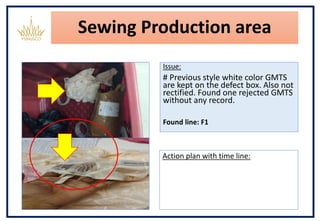

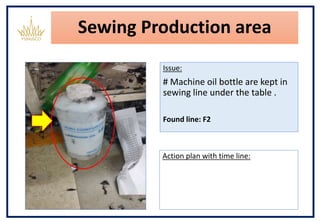

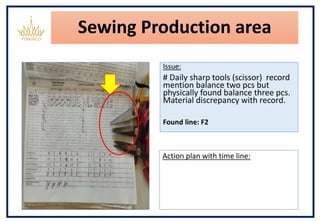

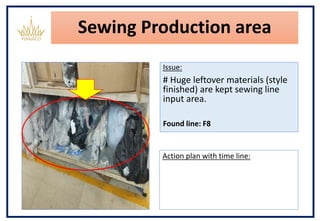

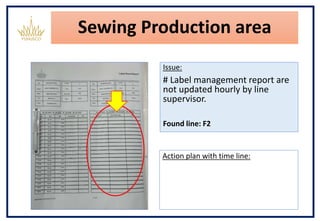

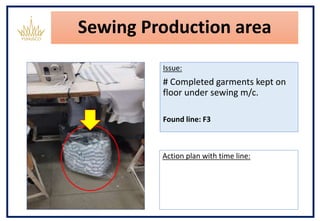

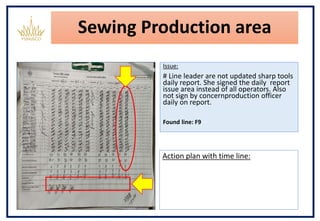

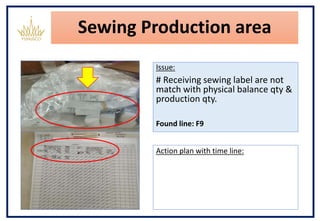

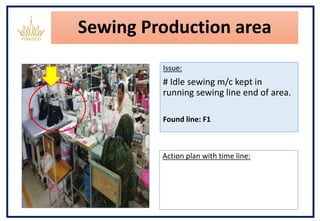

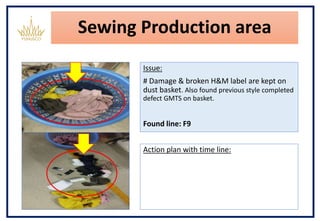

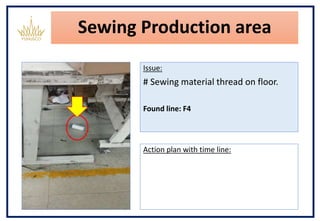

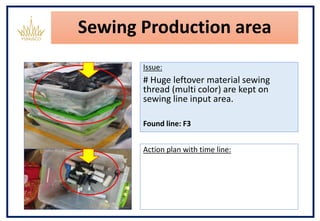

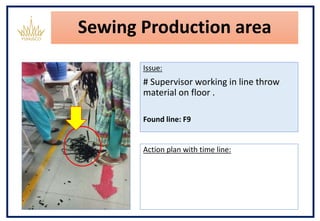

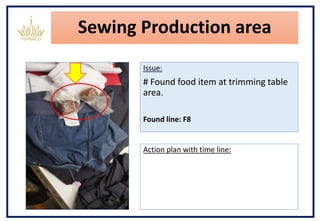

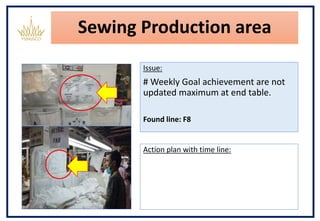

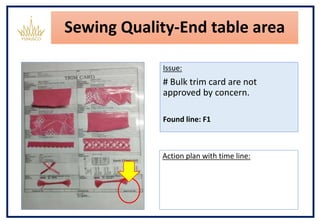

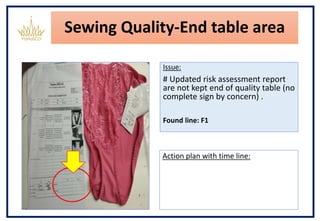

The internal technical audit report summarizes issues found across multiple sewing production lines. Key issues identified include improper storage and labeling of materials, tools, and garments; missing or outdated documentation like daily reports and risk assessments; and potential safety hazards from uncovered machinery or blocked aisles. The auditor recommends developing action plans and timelines to address each non-compliance in order to improve production, quality control, and workplace safety standards.