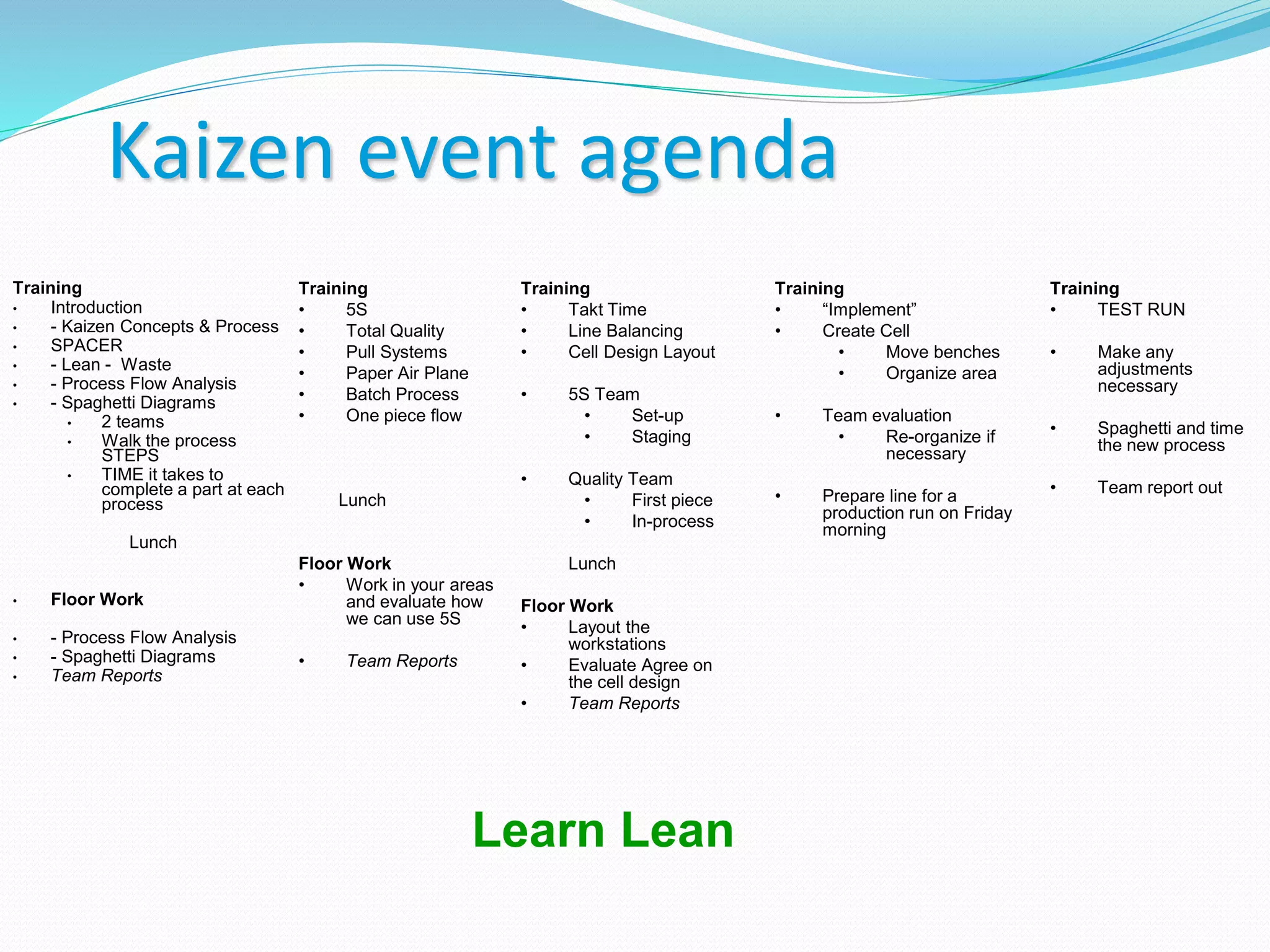

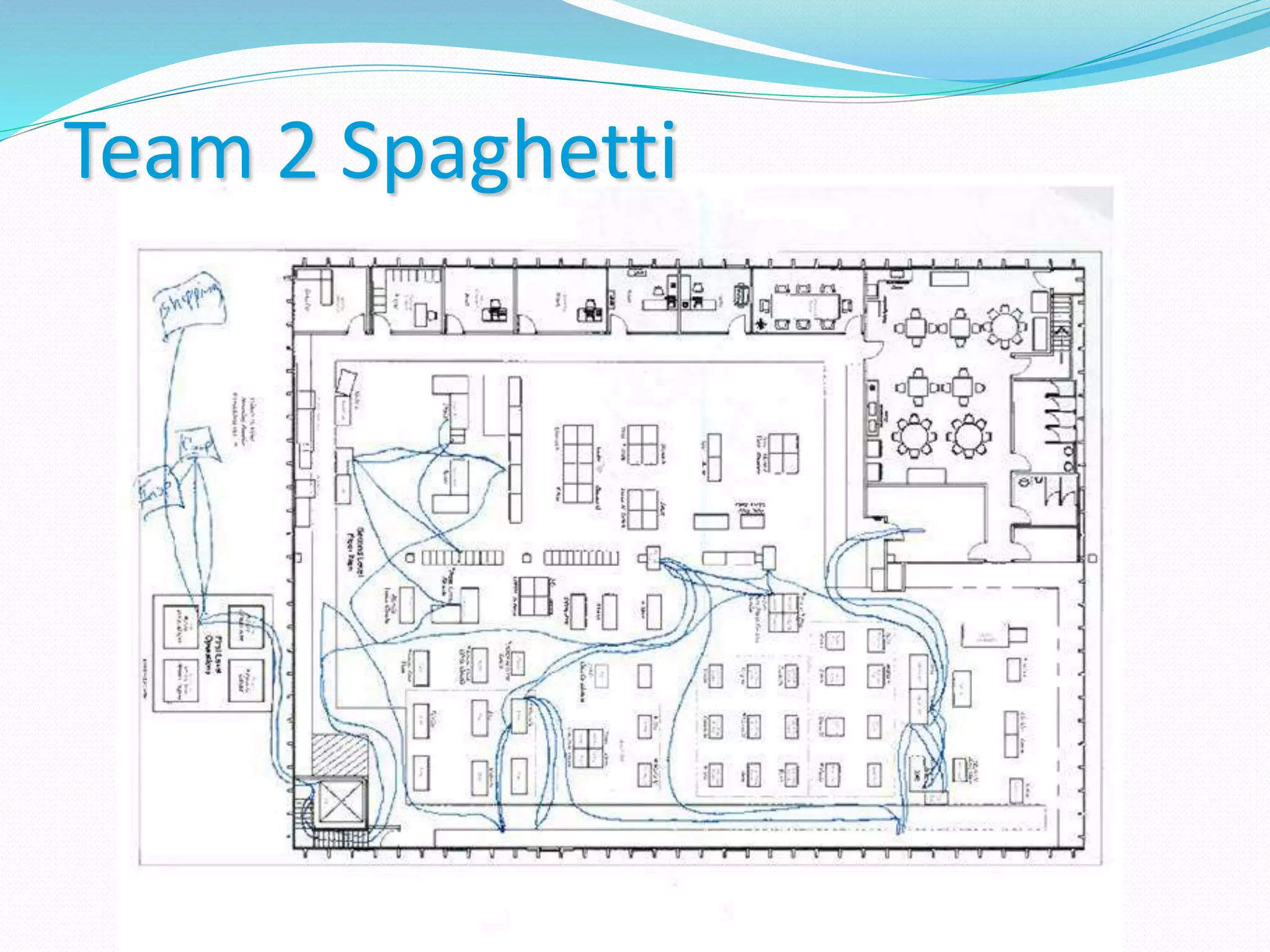

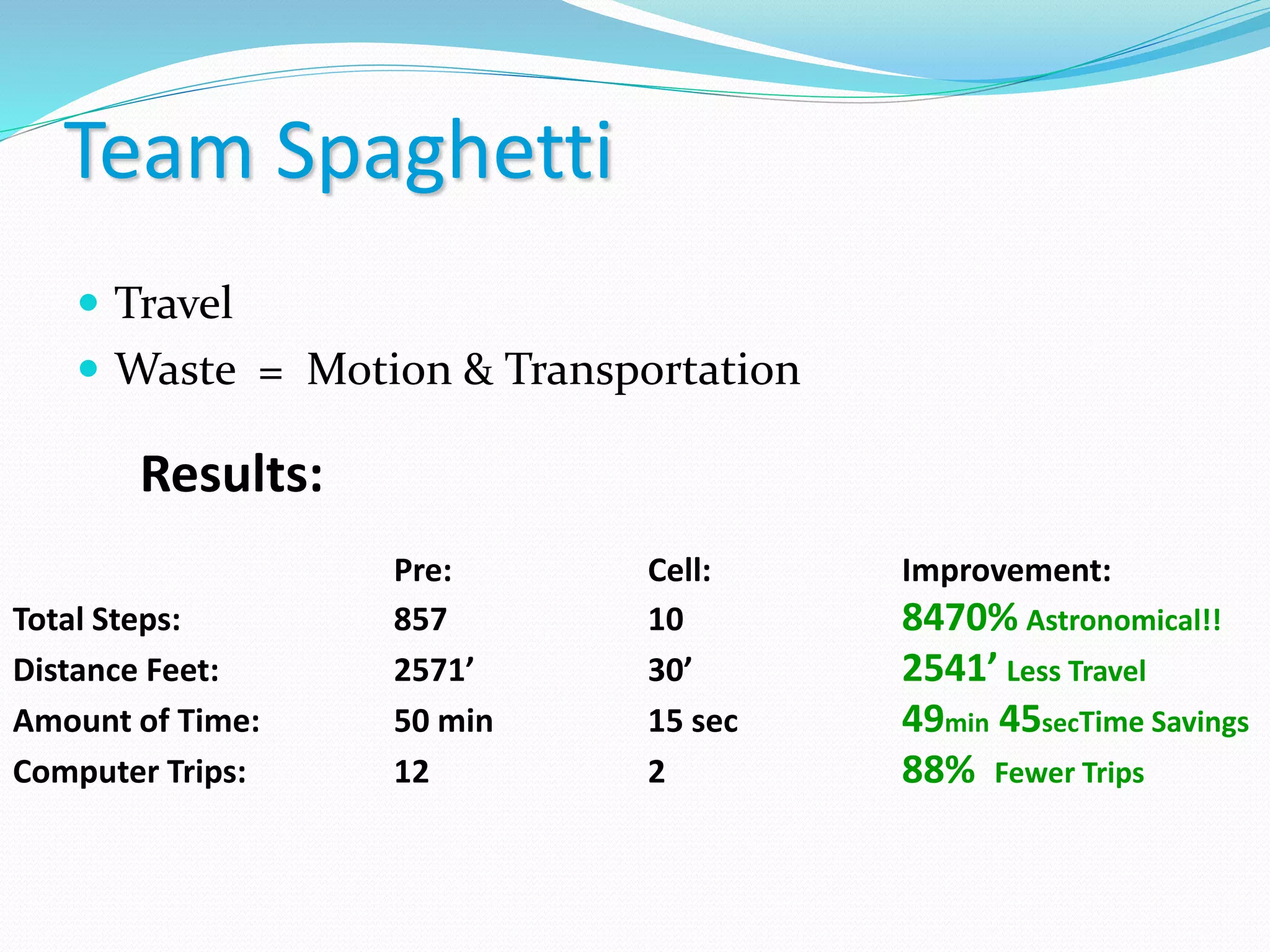

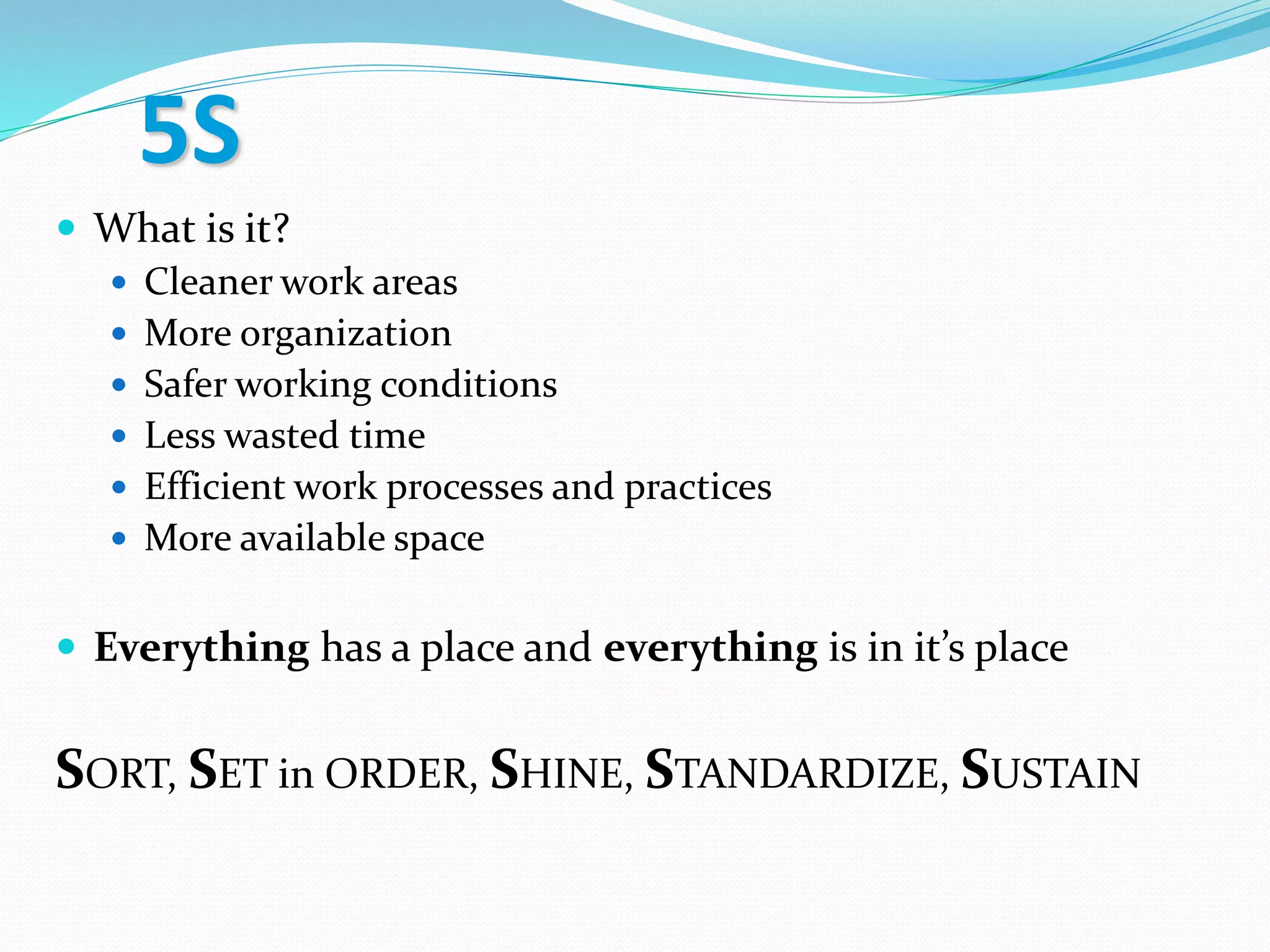

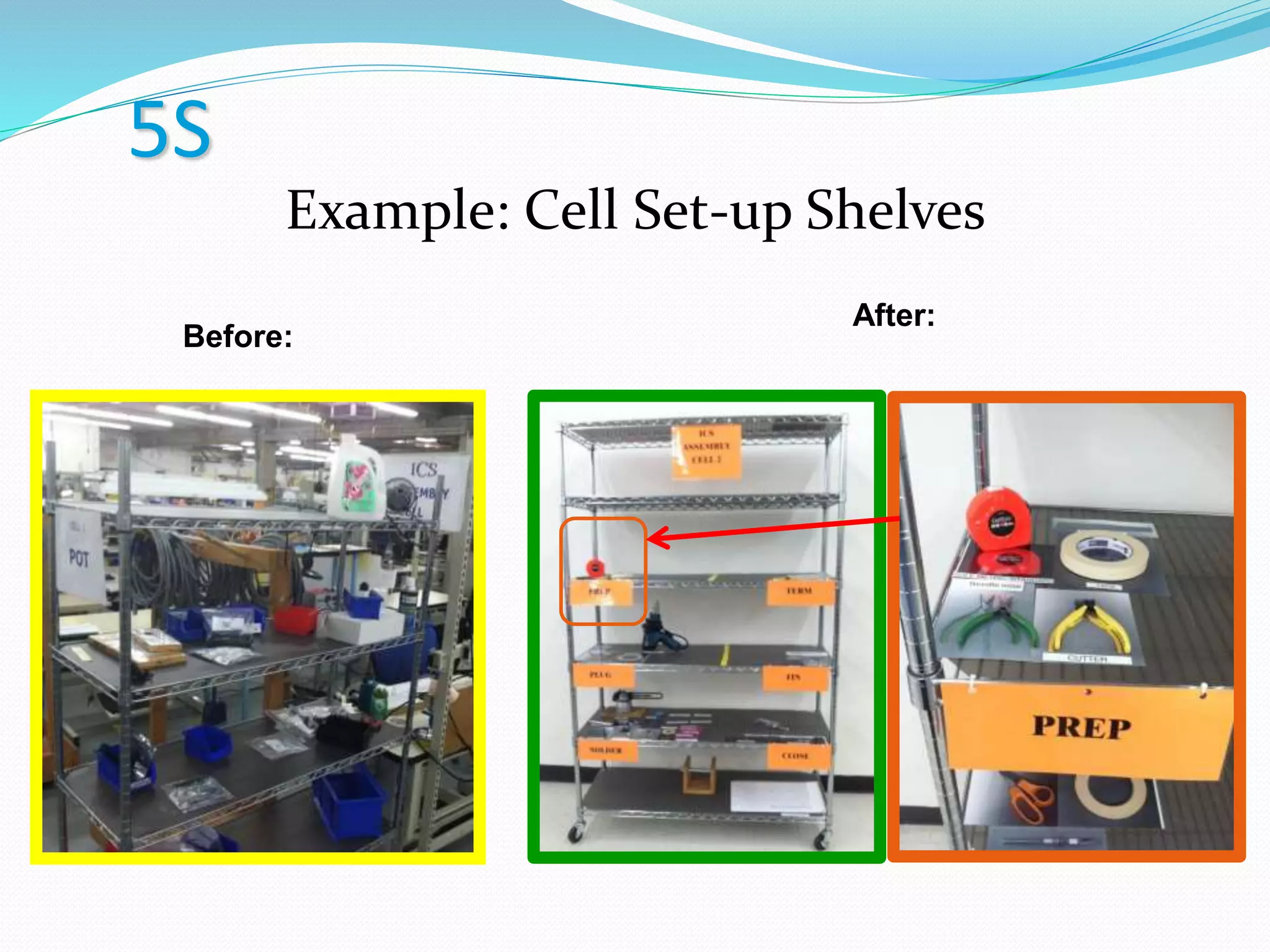

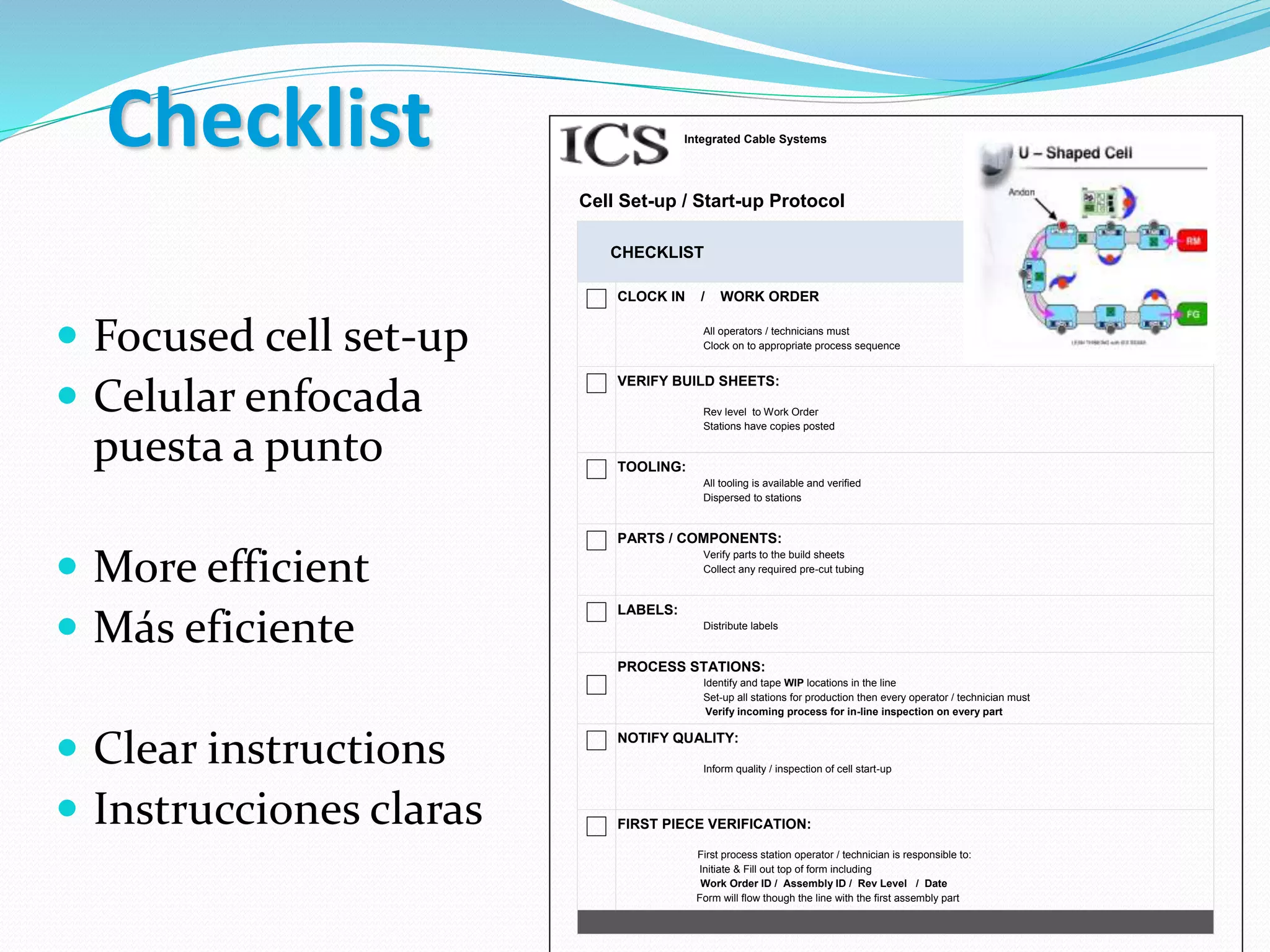

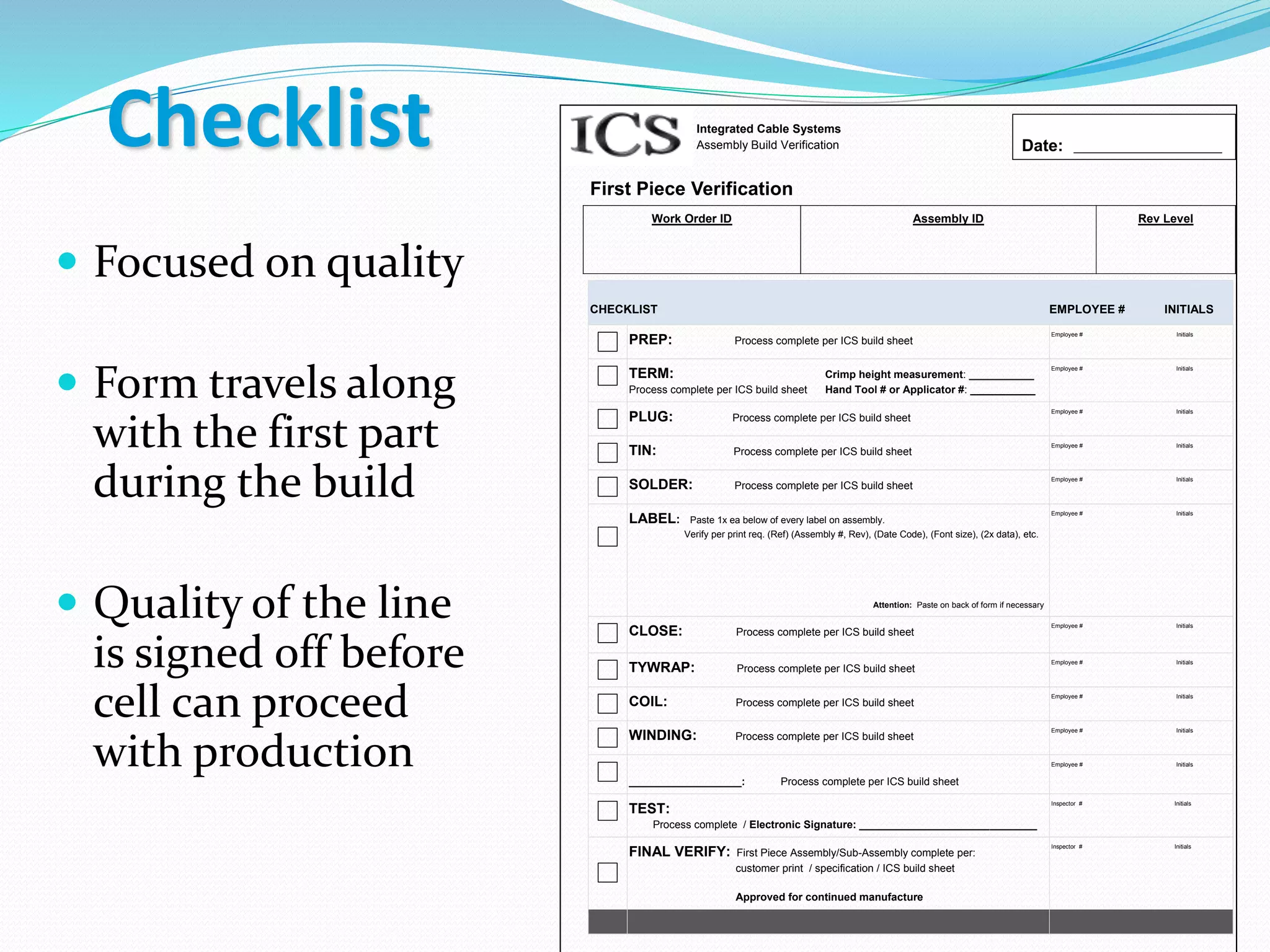

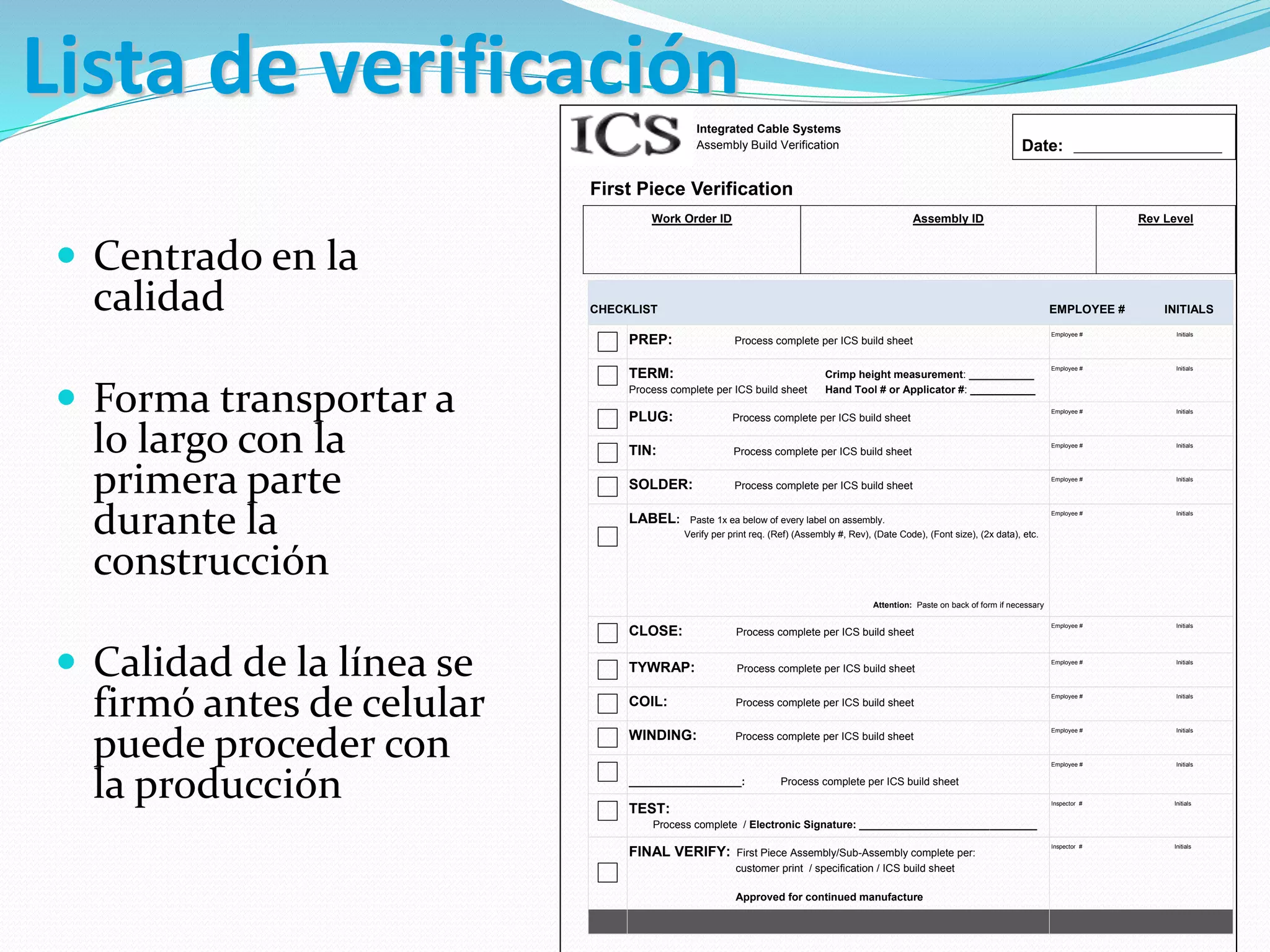

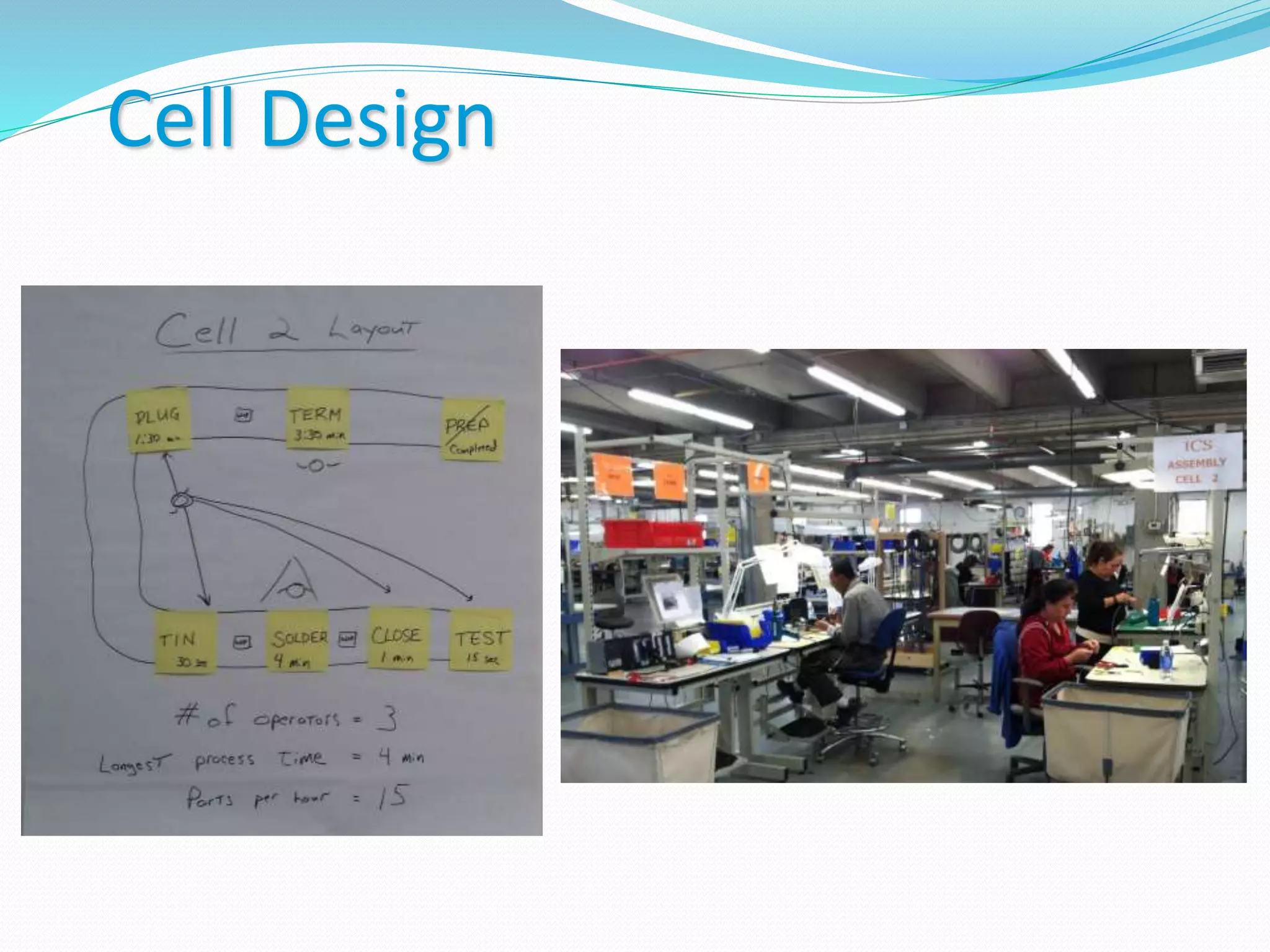

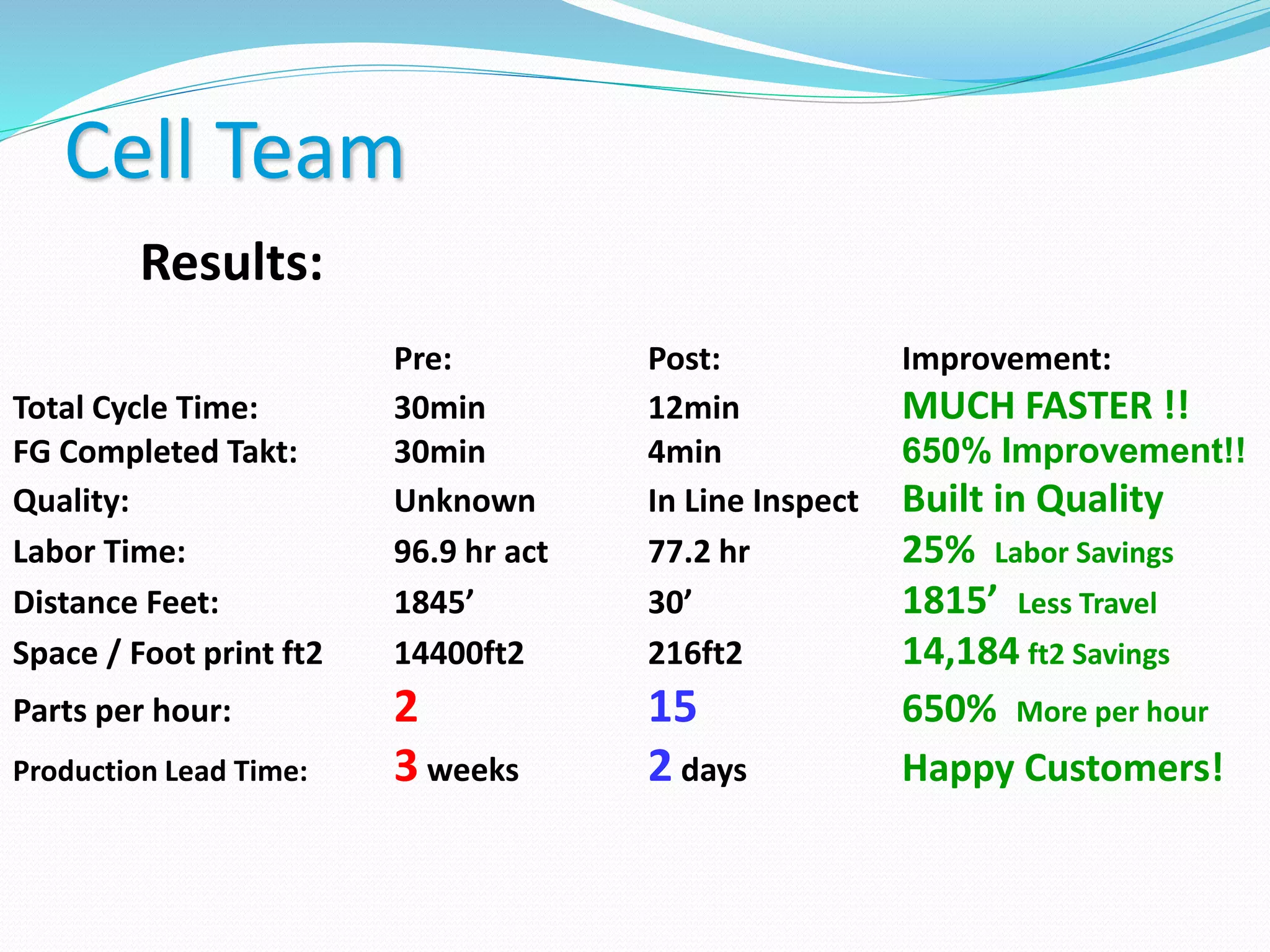

The document summarizes the agenda and activities for a Kaizen event focused on lean manufacturing at Integrated Cable Systems. The team of 9 members worked to create a competitive advantage through establishing quality protocols, lean concepts, and designing a new U-shaped cell layout. Through the event, the team was able to significantly reduce cycle time, increase production capacity, and realize labor savings through applying 5S methodology and implementing a pull-based one-piece flow cell.