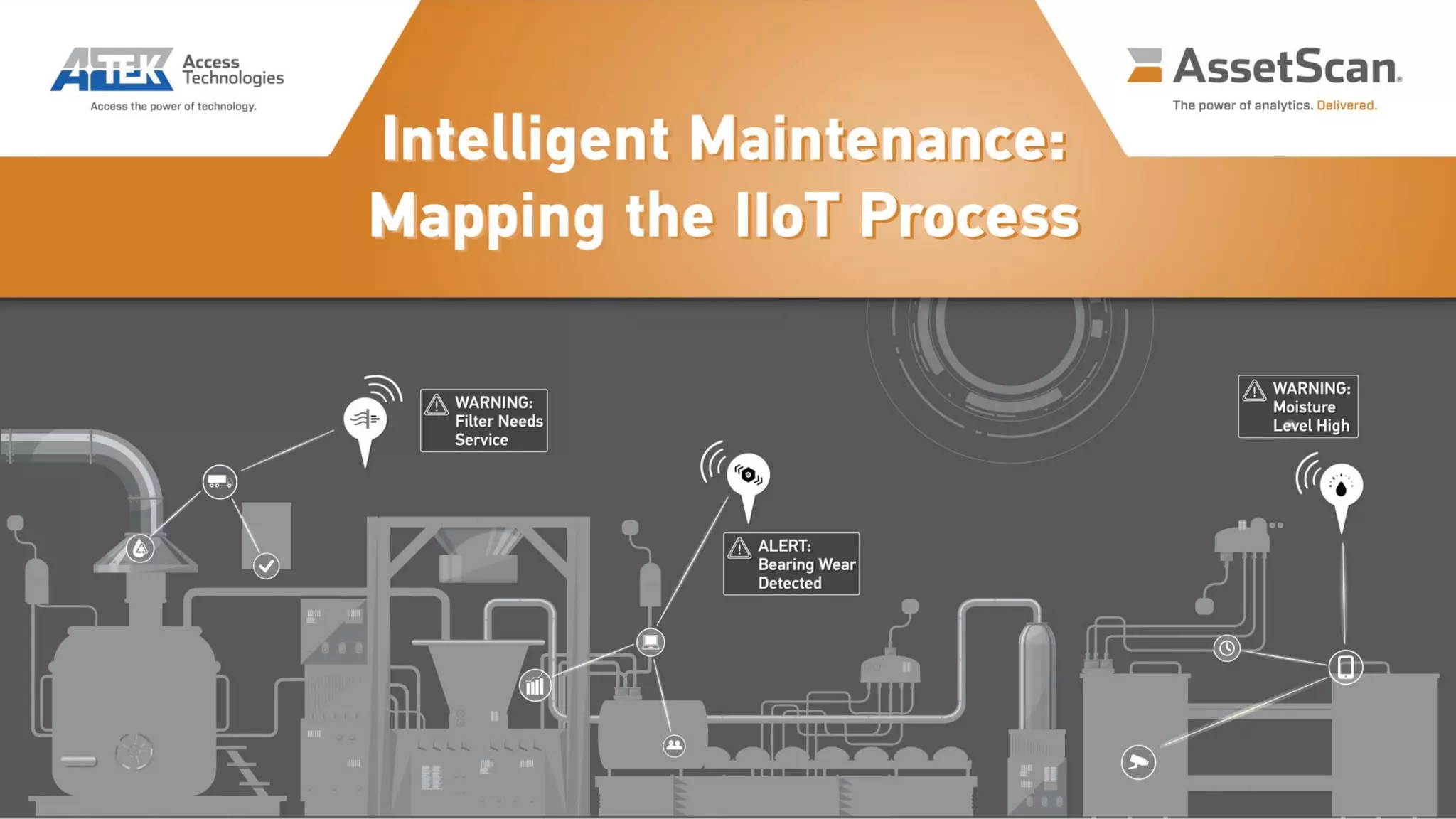

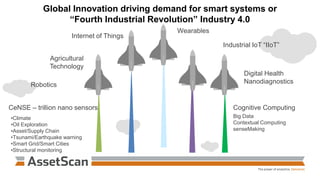

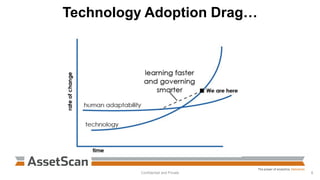

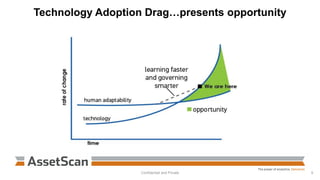

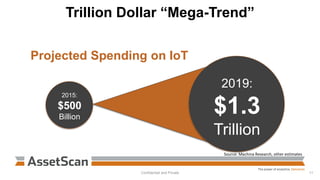

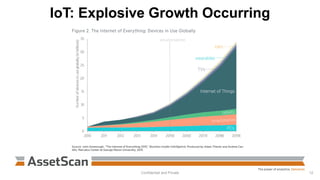

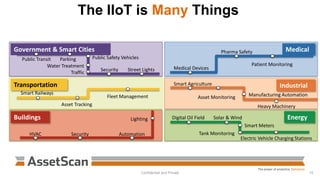

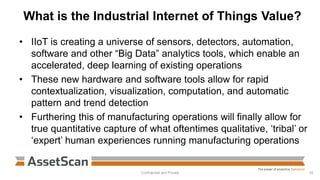

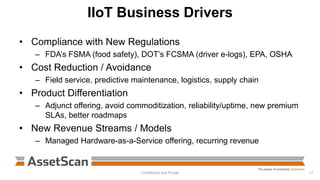

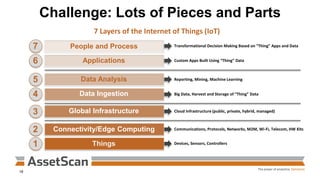

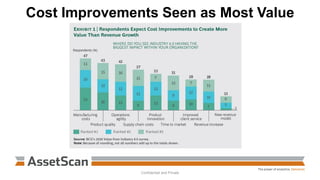

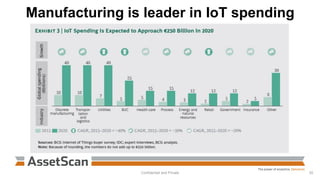

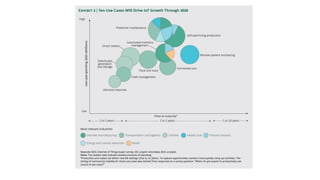

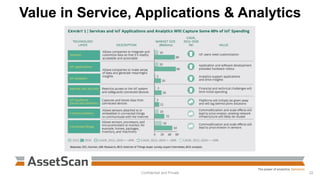

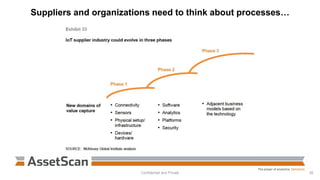

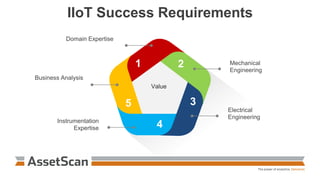

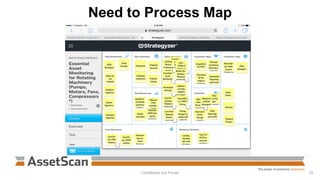

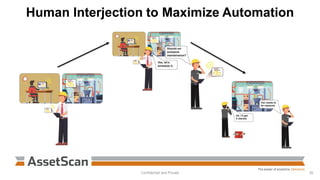

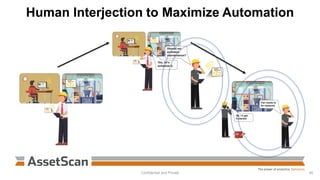

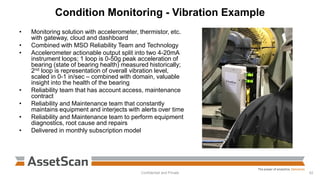

The document discusses the growth and opportunities presented by the Industrial Internet of Things (IIoT) and its impact on industrial systems, emphasizing the need for innovative strategies to remain competitive. It outlines the benefits of leveraging technology for predictive maintenance, enhanced asset monitoring, and improved workflows while addressing challenges like legacy systems and resource constraints. The concluding remarks highlight the importance of integrating technology with skilled personnel and structured processes to maximize the value of IIoT solutions.