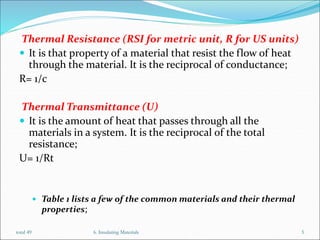

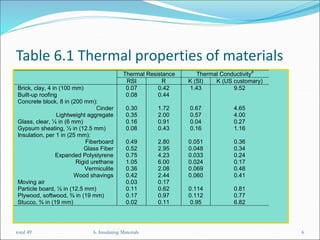

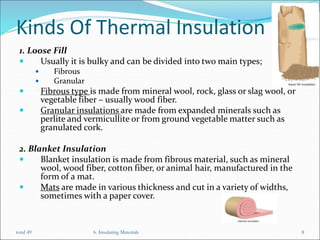

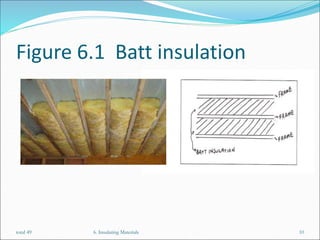

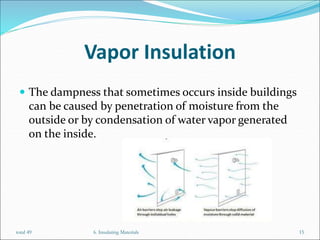

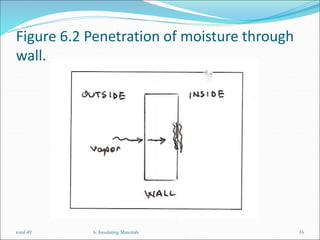

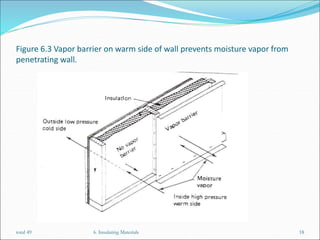

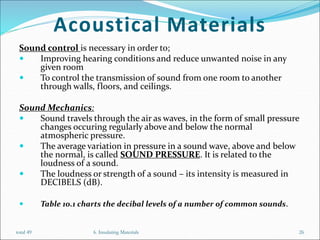

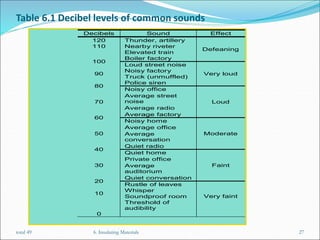

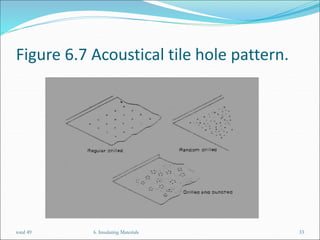

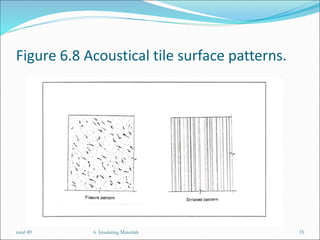

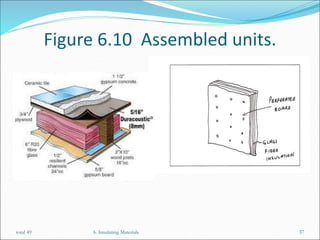

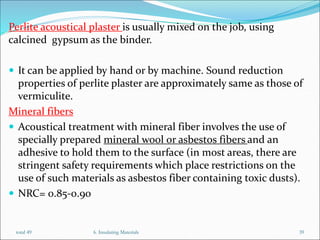

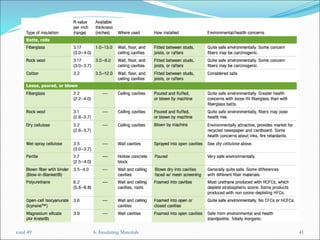

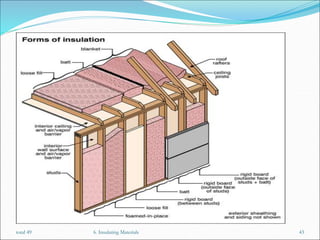

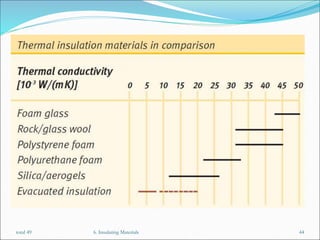

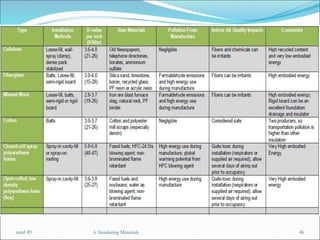

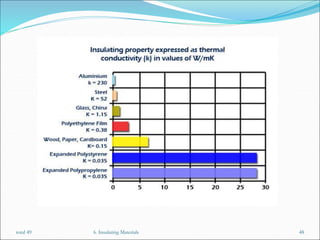

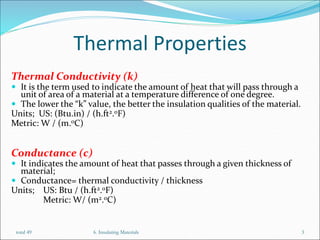

The document discusses various types of insulating and acoustic materials used in construction. It describes different insulating materials like loose fill, blankets, batts, and foam insulations. It explains concepts like thermal conductivity, resistance, and vapor barriers. Various acoustic materials are also outlined, including acoustical tiles made from fibers, assembled rockwool units, and sprayed-on materials. Tables provide data on common materials' thermal properties and noise levels.

![Example:

Determination of Thermal Conductivity Coefficient for

Different Wall Systems (TS EN ISO 8990)

6. Insulating Materials 4

1 Cold Chamber

2 Freeze Fan

3 Thermo- Couples (3 unit) [cold chamber]

4 Thermo- couples (9 unit) [Surface]

5 Wall specimen (1.2 x 1.2 m)

6 Thermo- couples (9 unit) [Surface]

7 Hot Chamber

8 Thermo- Couples (3 unit) [hot chamber]

9 Heather Fan

total 49](https://image.slidesharecdn.com/insulatingmaterials-240220143214-4c648914/85/Insulating-Materials-used-in-construction-4-320.jpg)