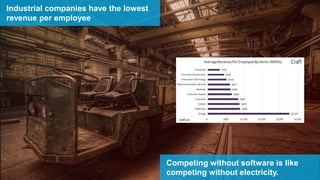

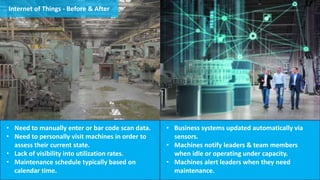

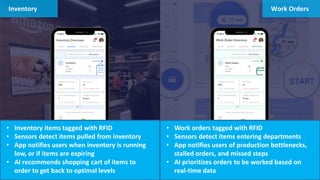

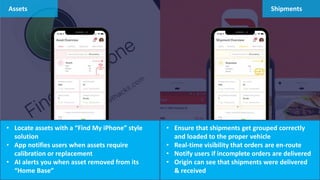

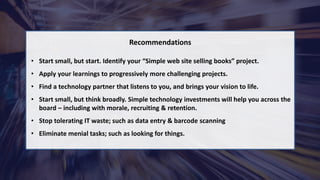

The document discusses the Industry 4.0 revolution, highlighting the significance of cloud, mobile, AI, and IoT technologies in transforming industrial operations. It emphasizes that companies will compete based on their ability to implement Industry 4.0 solutions, rather than relying on low-cost talent. Recommendations include starting small with technology investments and finding partners who can bring their visions to life.