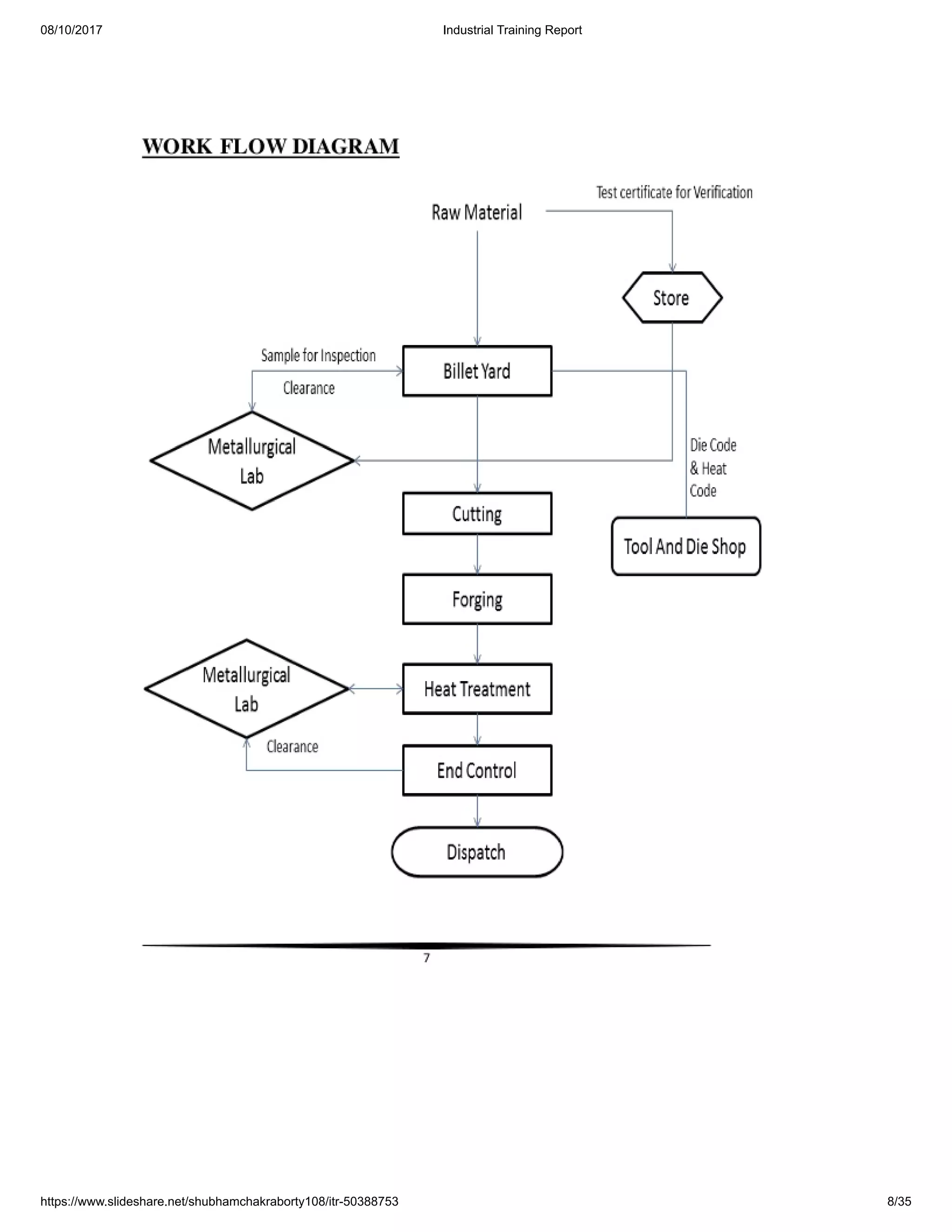

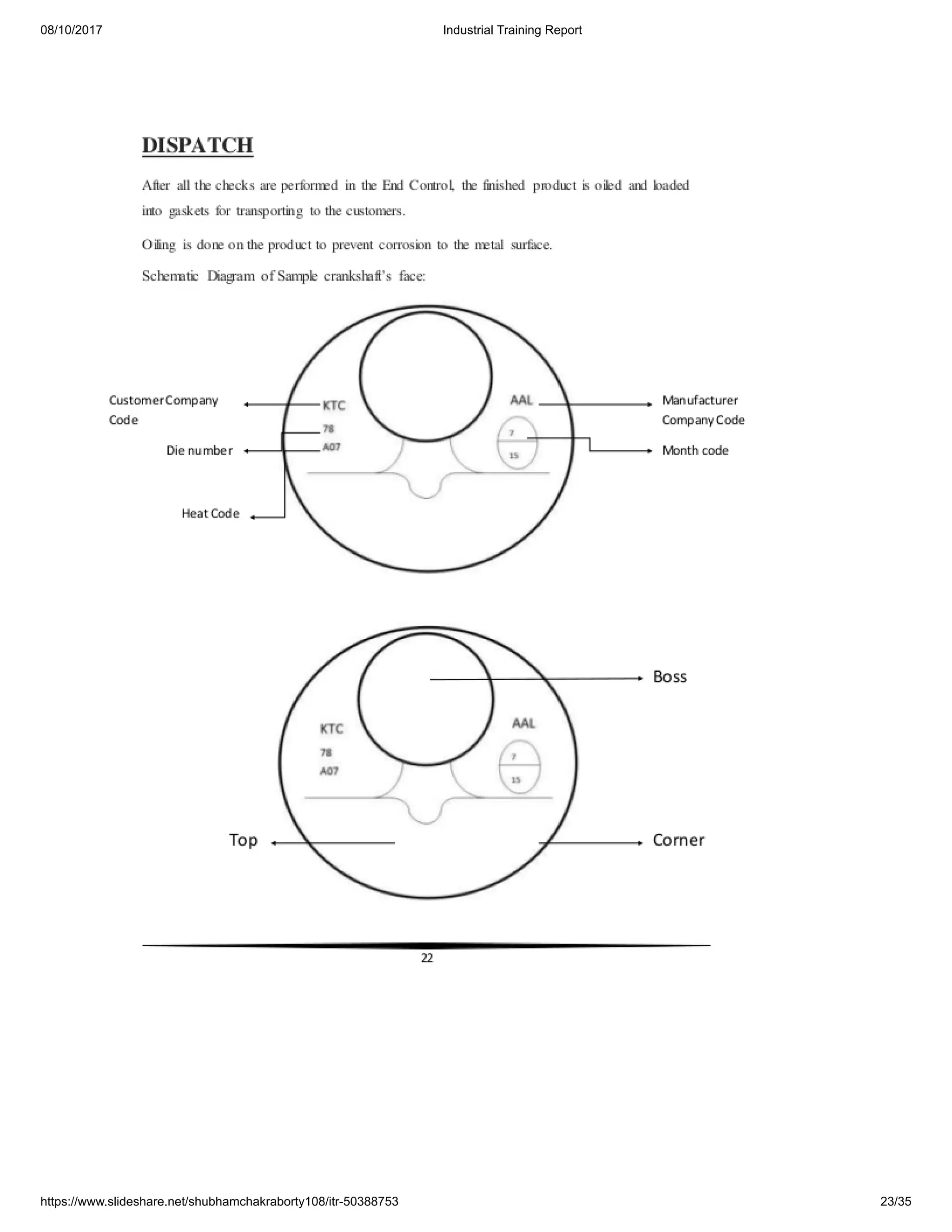

The document appears to be an industrial training report submitted by Shubham Chakraborty after completing a 15-day training at AMTEK AUTO LIMITED. It provides an overview of AMTEK AUTO LTD, including its various divisions and product range. The report also includes sections on the raw material grading, tool and die shop, metallurgical lab, billet yard processes, forge shop processes, heat treatment processes, end control checks and dispatch procedures at AMTEK AUTO LTD.