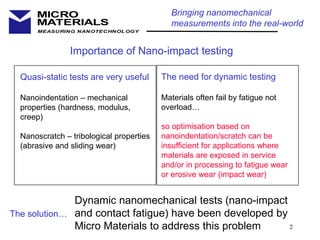

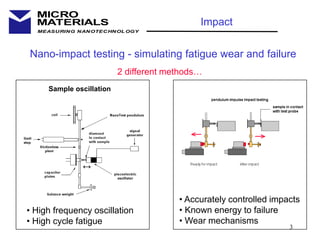

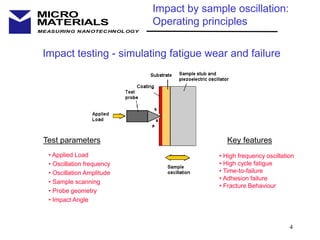

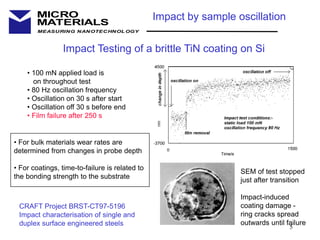

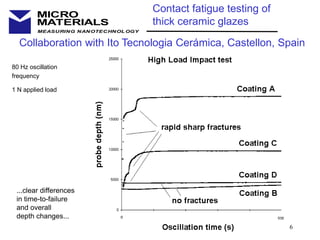

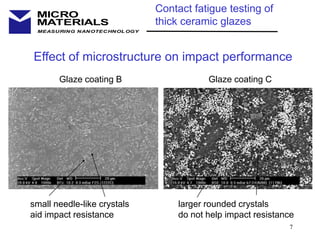

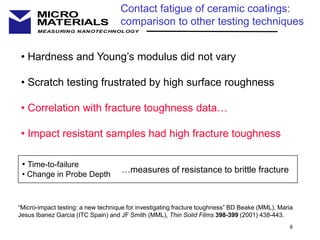

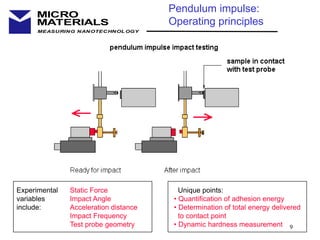

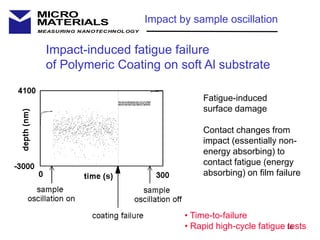

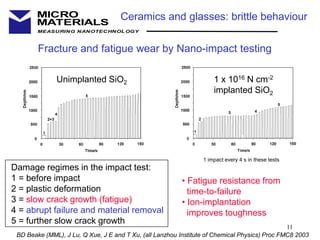

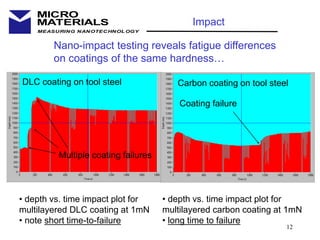

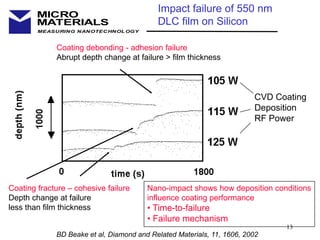

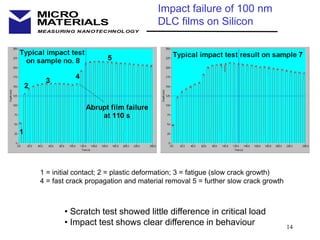

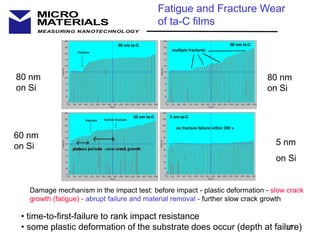

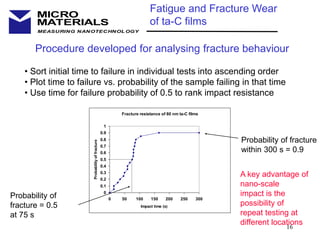

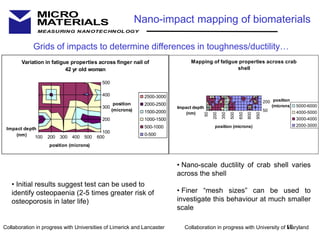

The document details advanced nano-impact testing techniques to assess the dynamic mechanical properties and performance of materials, particularly focusing on fatigue wear and failure in coatings and ceramics. It highlights the capabilities of measuring adhesion energy, dynamic hardness, and time-to-failure across various materials and conditions. The testing aims to bridge the gap between theoretical nanoindentation results and real-world applications, enabling better prediction and optimization of material behavior under fatigue conditions.