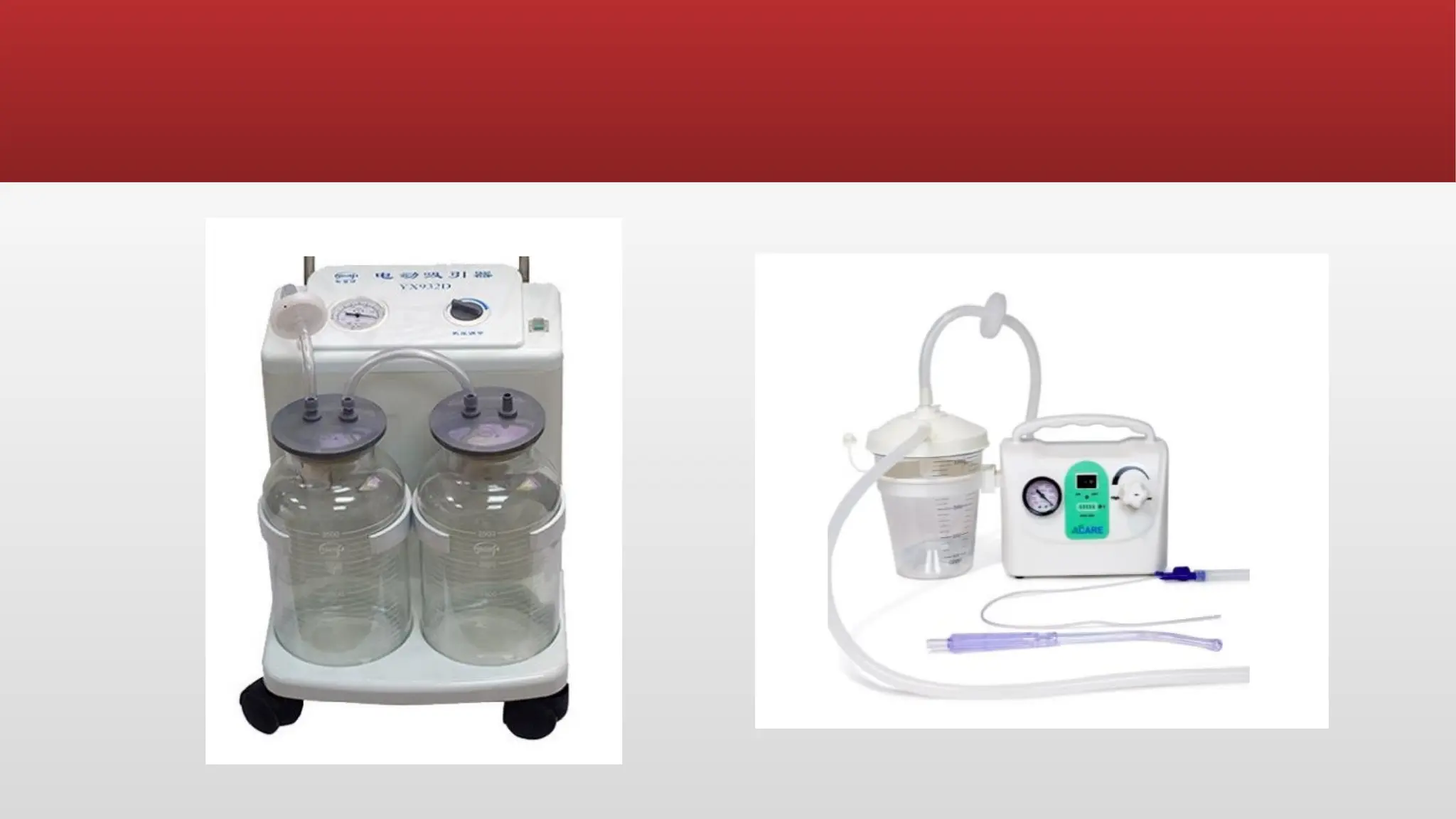

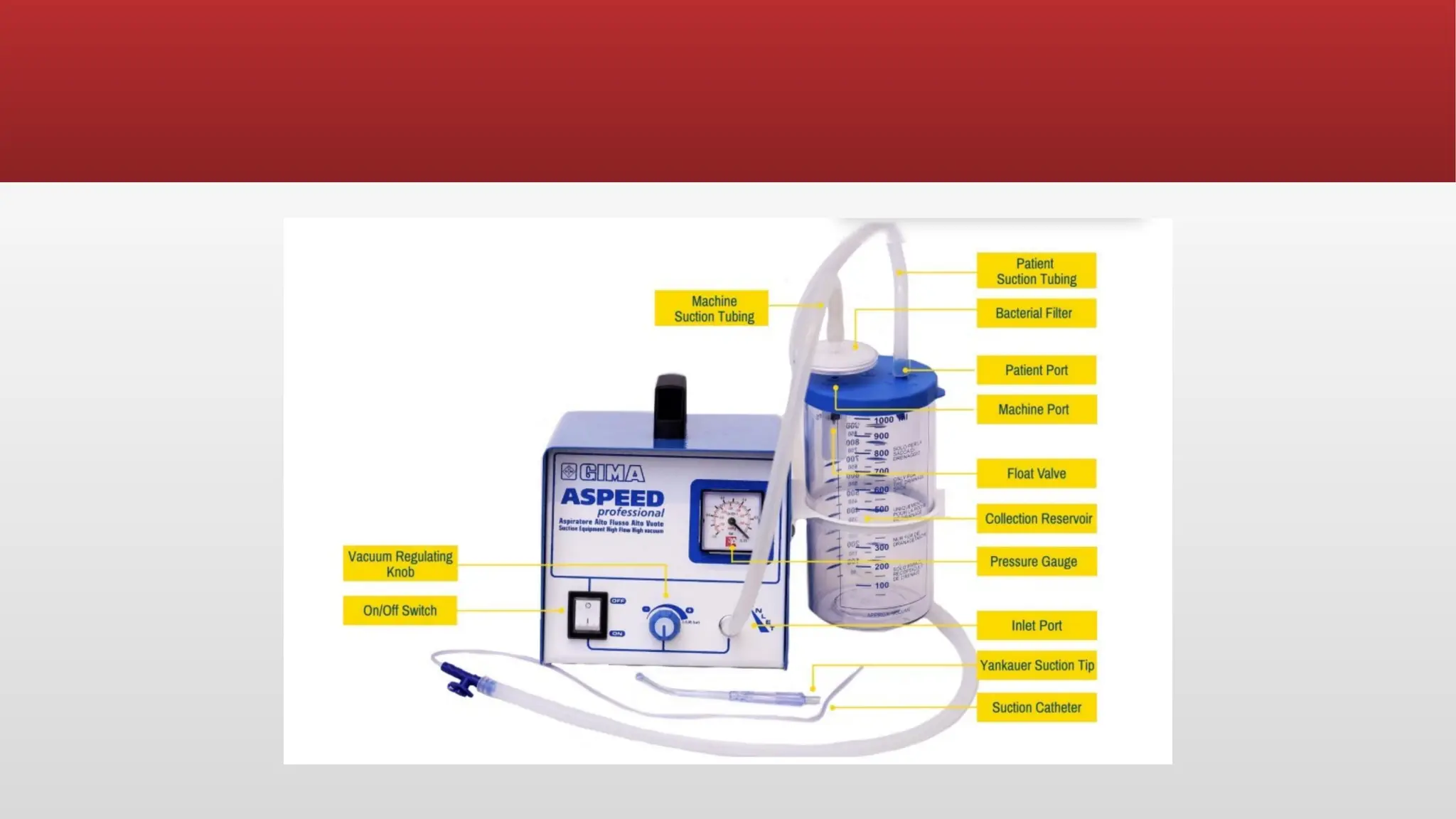

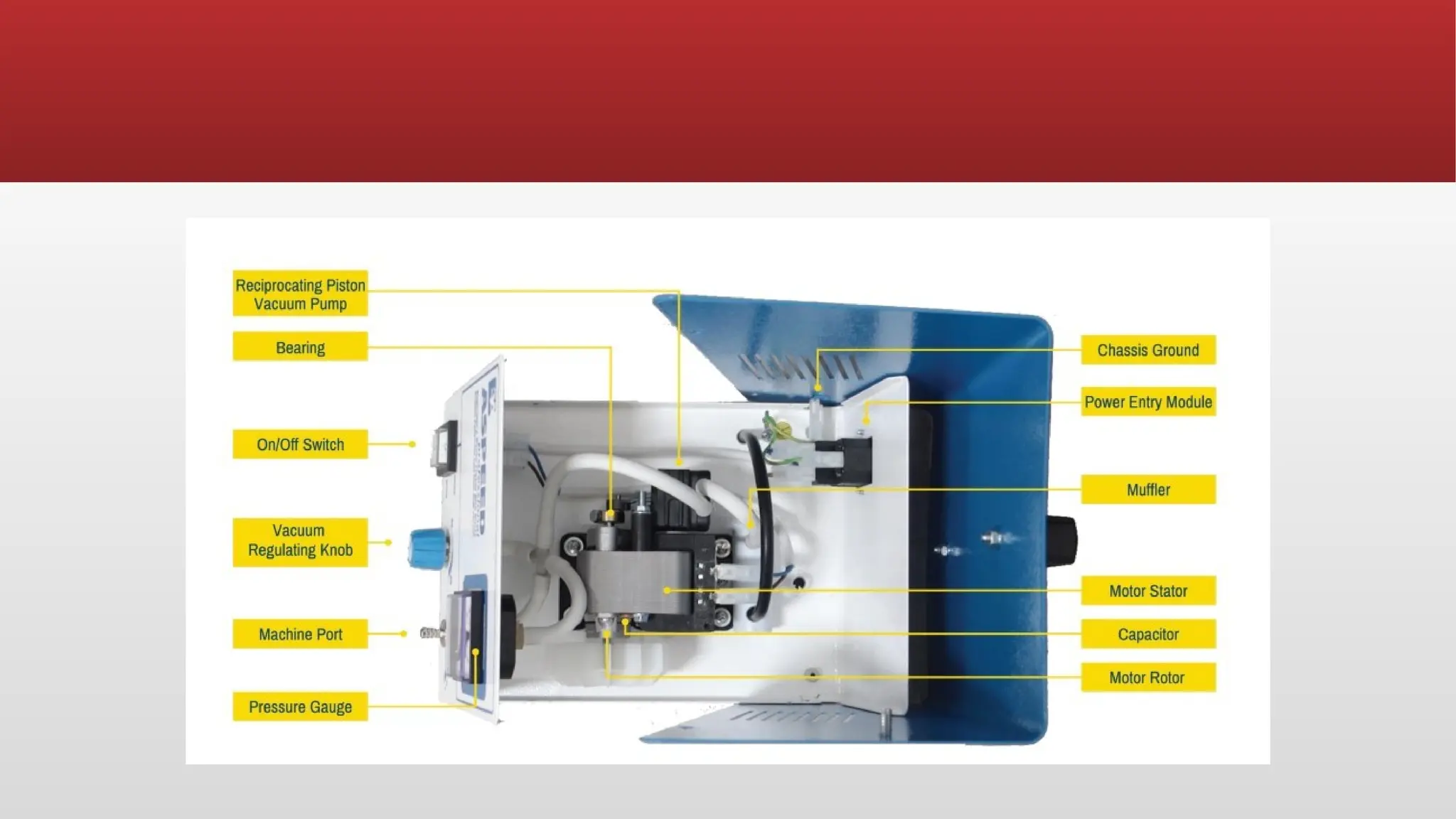

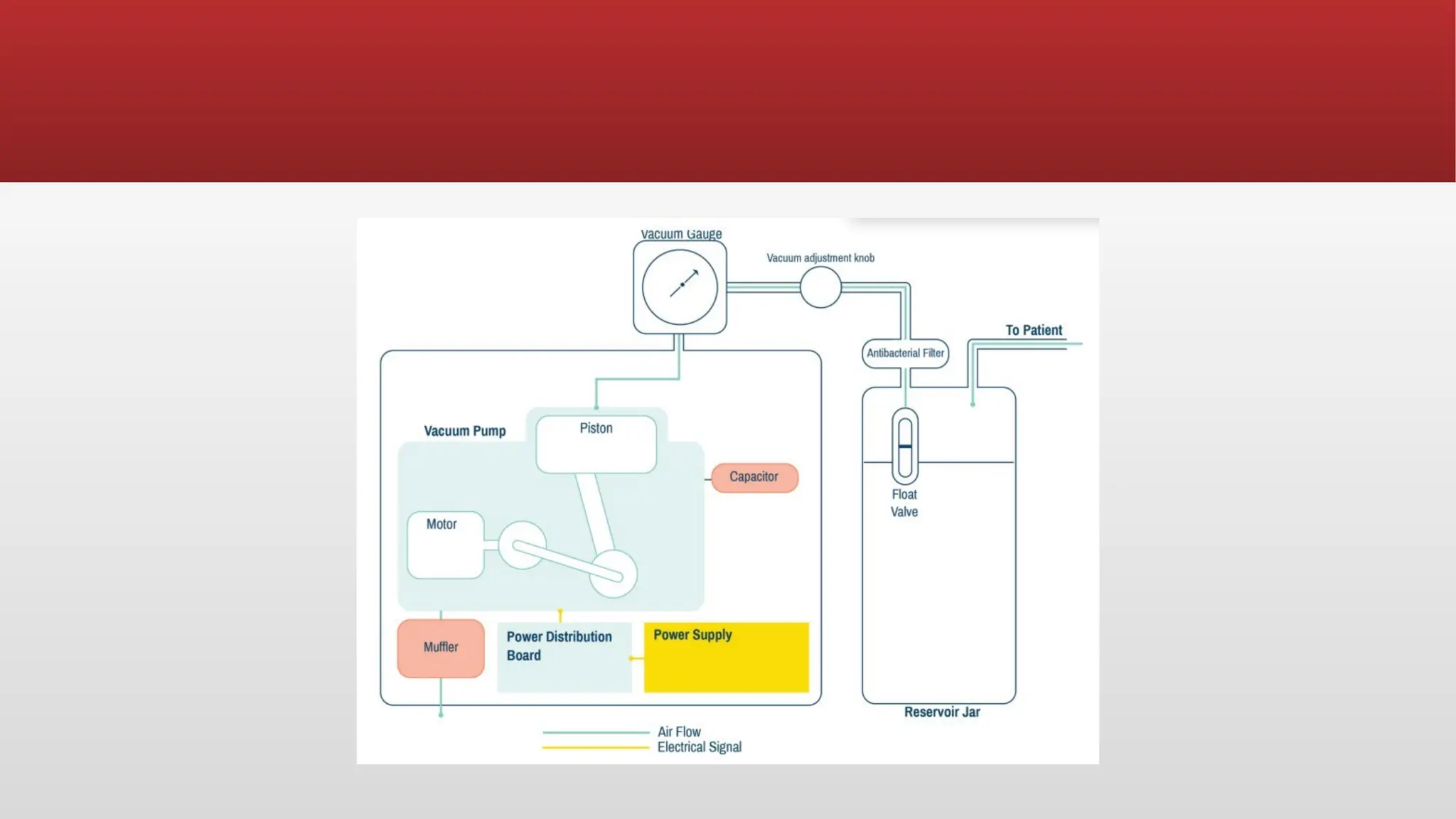

The document provides a comprehensive overview of suction machines used in medical settings, detailing their introduction, uses, components, and maintenance. It explains the working principle and various parts of the machine, including the vacuum pump, collection reservoir, and bacterial filter. Additionally, it covers planned preventive maintenance and troubleshooting tips for common issues encountered with the suction pump.