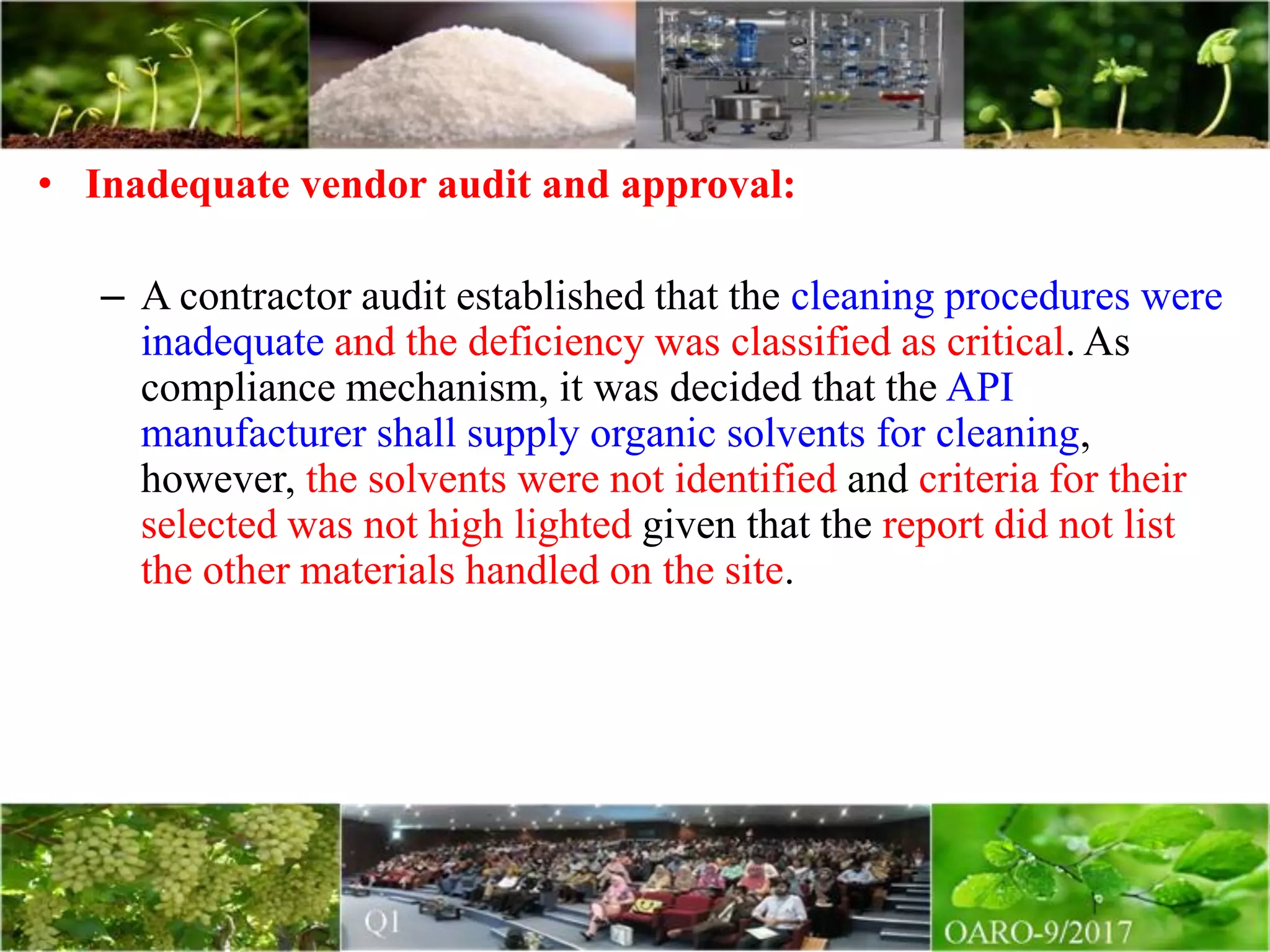

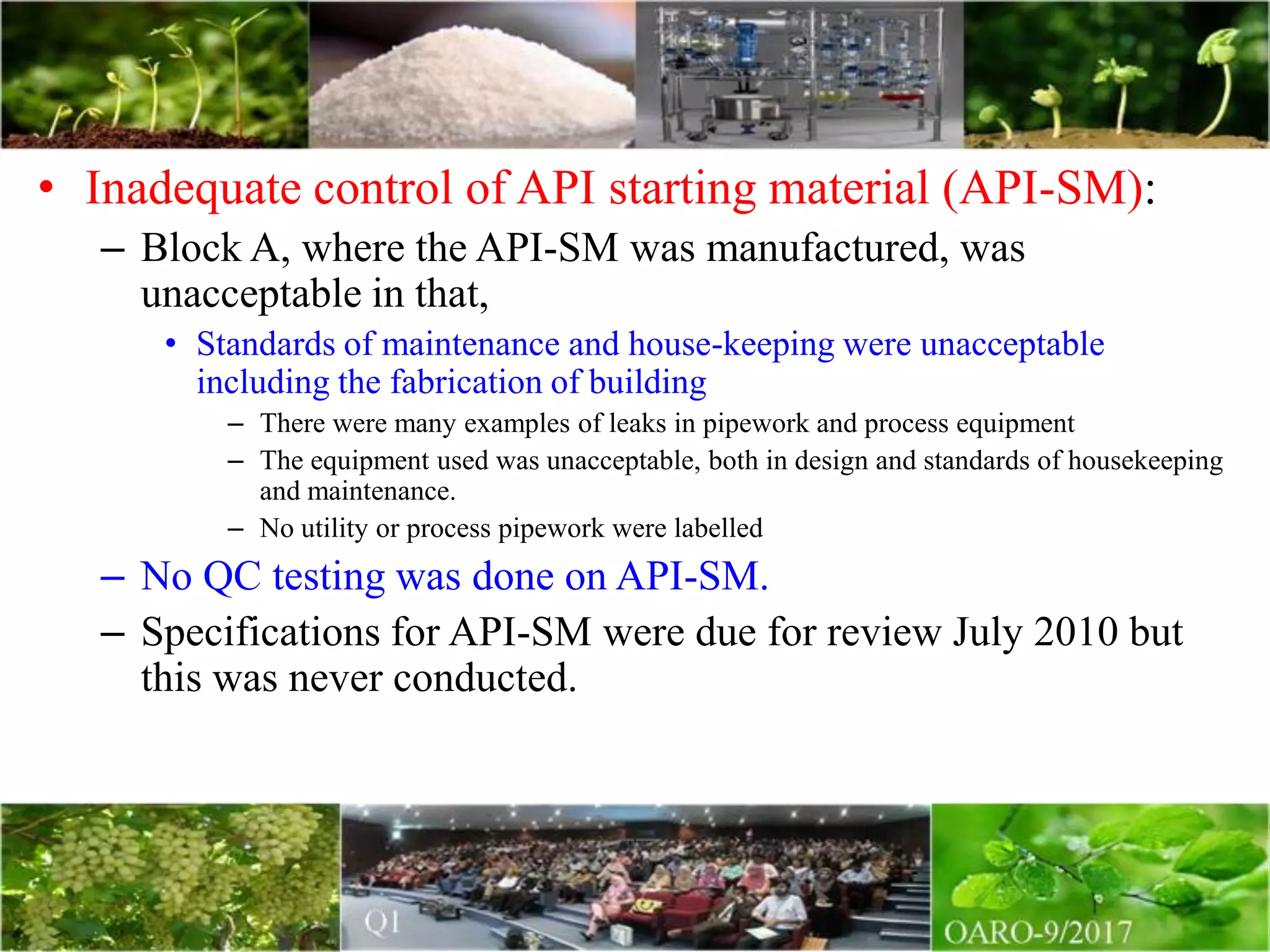

The document discusses perspectives on ICH Q7 and Q11 from scientific and regulatory viewpoints. It summarizes common GMP deficiencies observed during API inspections, including inadequate vendor audits that failed to properly evaluate supplier quality systems and cleaning procedures. Specific examples call out insufficient control of API starting materials due to unacceptable facility maintenance and lack of testing, as well as inadequate sampling and improper storage of materials.