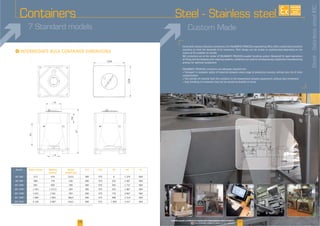

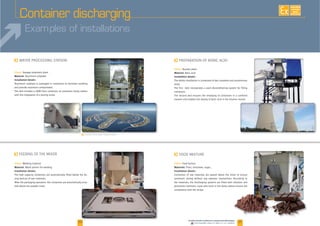

This document provides information on container and storage solutions from Palamatic Process. It discusses their range of powder handling solutions including automatic and manual filling systems for IBC containers, container discharging and blending stations, and flexible silos. The document provides technical specifications and advantages for the different equipment types and gives examples of installations and applications in industries like chemicals, food, and pharmaceuticals. Custom configurations are available and the company's test center allows testing of different materials.