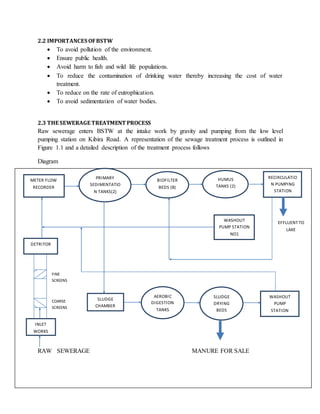

The Bugolobi Sewerage Treatment Works (BSTW) is located in Kampala, Uganda and treats sewage from approximately 8% of the city. It receives sewage via sewer lines and pumping stations and treats the sewage using preliminary screens, grit removal, primary sedimentation, trickling filters, secondary clarifiers, sludge digestion, and sludge drying beds before discharging the treated effluent into the Nakivubo Channel. The BSTW is an important infrastructure for treating Kampala's sewage and preventing environmental pollution.