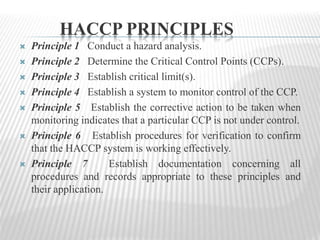

HACCP (Hazard Analysis and Critical Control Point) is a systematic approach to identify and mitigate hazards in food production to ensure safety and prevent health risks. It addresses biological, chemical, and physical hazards, outlining specific principles for hazard analysis, control points, and monitoring processes. The implementation of HACCP offers significant benefits to consumers, the food industry, and governments by reducing foodborne disease risks and improving public health.