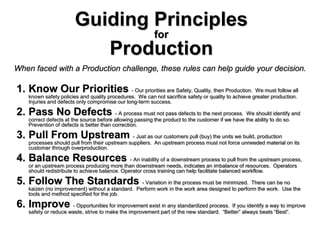

Our priorities are safety, quality, then production. We cannot sacrifice safety or quality for greater production as injuries and defects compromise long-term success. A process must not pass defects downstream and should identify and correct defects at the source before passing products to customers if able. Production processes should pull from upstream suppliers just as customers pull products, and upstream processes should not force unneeded material on downstream processes through overproduction.