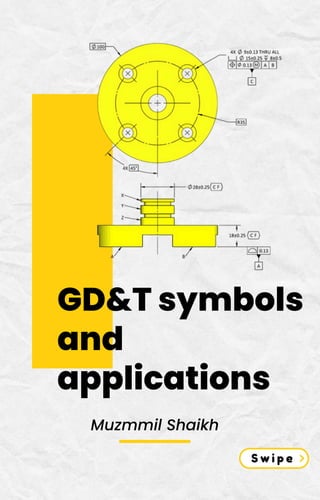

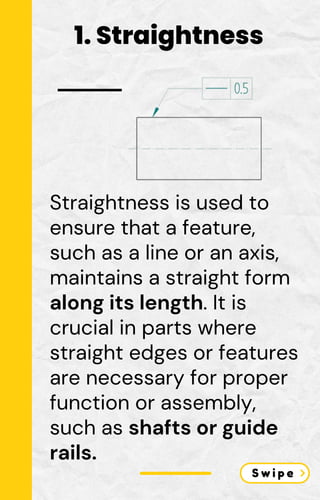

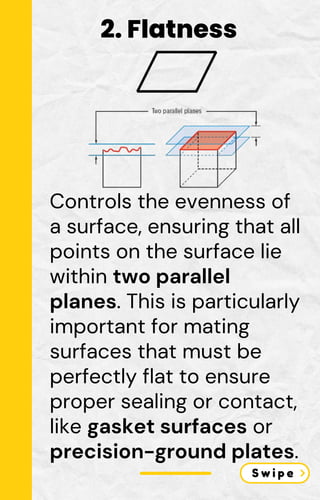

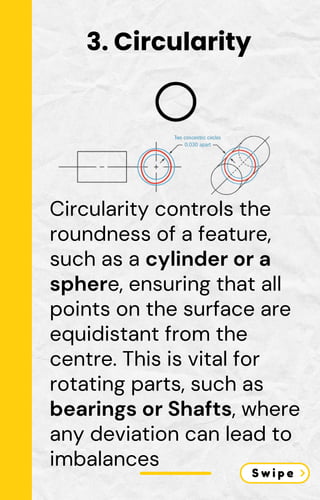

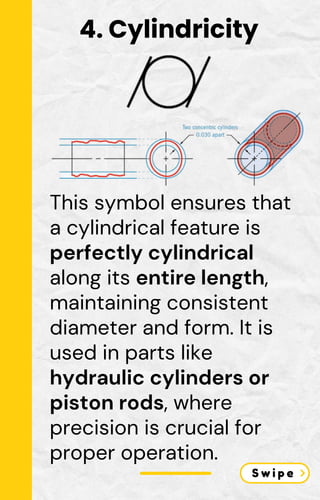

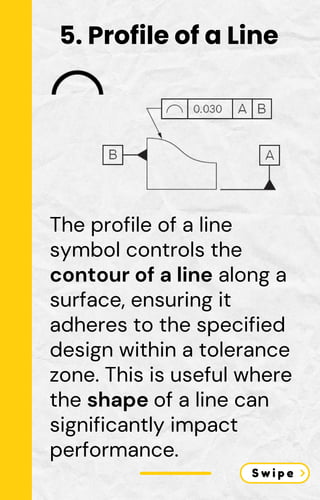

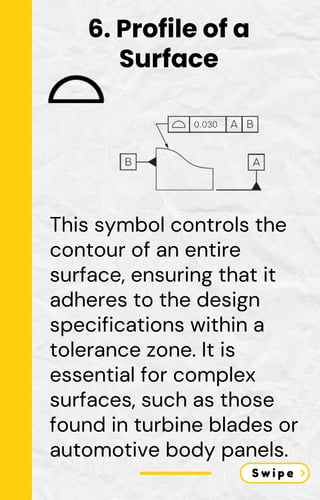

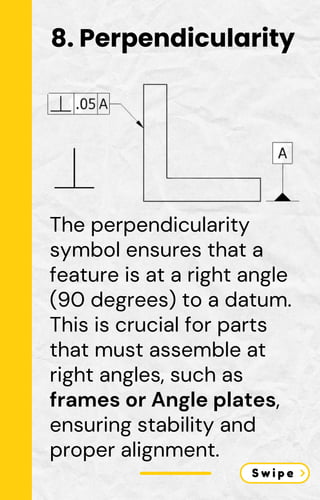

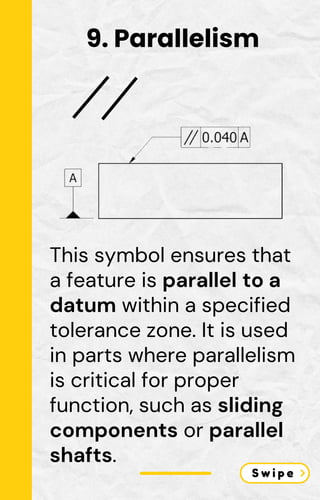

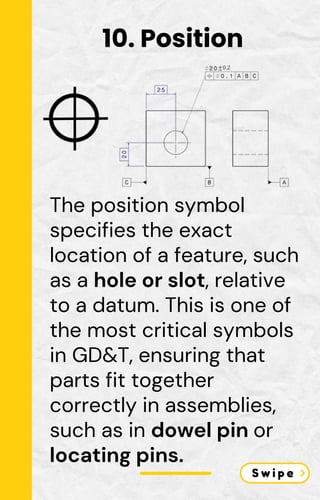

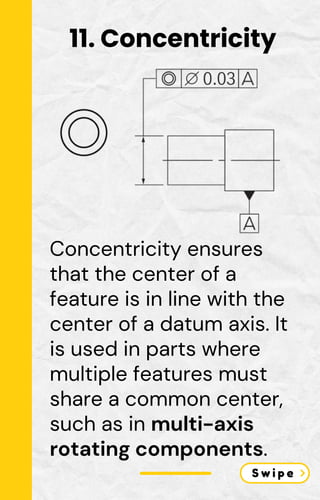

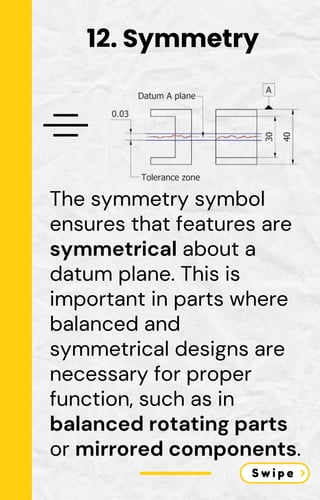

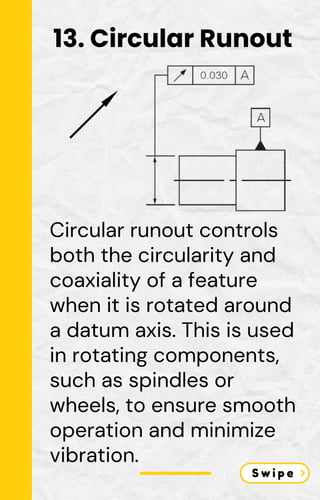

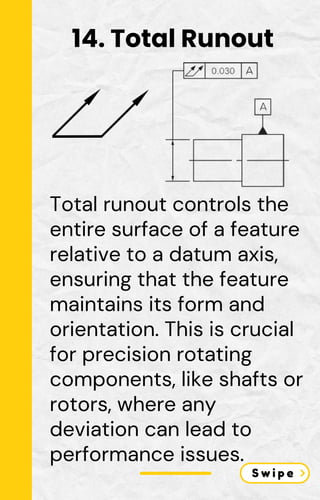

The document outlines various Geometric Dimensioning and Tolerancing (GD&T) symbols and their applications, emphasizing their importance in ensuring the precision and functionality of mechanical components. Key symbols discussed include straightness, flatness, circularity, cylindricity, angularity, perpendicularity, parallelism, position, concentricity, symmetry, circular runout, and total runout. Each symbol is critical for maintaining specific design characteristics necessary for proper assembly and operation of parts like shafts, bearings, and rotating components.