Geomembrane Welding Machine

•

1 like•93 views

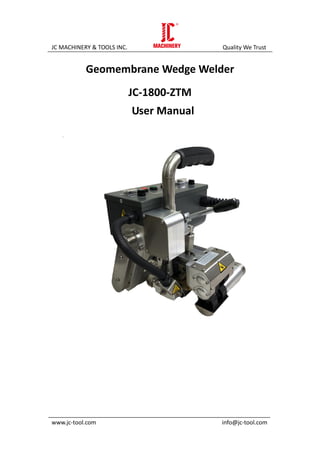

The document provides a user manual for the JC-1800-ZTM Geomembrane Wedge Welder. It describes the welder's applications for welding various materials, technical specifications, operation instructions, maintenance procedures, and troubleshooting tips. The welder can be used to weld materials like PE, PVC, HDPE and more with settings for temperature up to 450°C, welding speed from 0.5-8 m/min, and material thickness from 0.2-2mm. The user manual explains how to set welding parameters and use the welder's various functions.

Report

Share

Report

Share

Download to read offline

Recommended

JC-4200 WM Roof Waterproofing Membrane Welder

Roof waterproofing membrane welder is a new type hot air machine specially made for roof waterproofing membrane welding. By strong R&D engineering team, our machine equips advanced hot air heating technology, intelligent electronic temperature control and speed control system. According to practical material thickness especially for TPO or other poly waterproofing membrane, counterweight can be adjusted in order to modify welding pressure ro provide excellent welding performance, like uniform welding, no leakage, no wrinkles, high strength.

Geomembrane Overlap Wedge Welder

It adopts advanced hot wedge structure, With its high power, high speed and pressure, it welds 1.0mm – 3.0mm thickness hot melting materials such as HDPE, LDPE, PVC, EVA, ECB, PP and others This machine is specially designed for water conservancy, aquaculture, landfills, chemical mining, sewage treatment, roof constructions and other waterproofing projects.

Geomembrane Welding Machine

It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

JC-tool.com

IRJET- Design and Analysis of Friction Stir Welding using Dissimilar Alloys (...

https://www.irjet.net/archives/V5/i4/IRJET-V5I427.pdf

IRJET-Study of Mechanical Properties of Friction Stir Welded Joint of Similar...

https://irjet.net/archives/V5/i6/IRJET-V5I6268.pdf

Met weld - Welding Machine Manufacturers - ahmedabad - gujarat - INDIA

Metweld - Leading Indian manufacturers and exporter of Welding Machine, Welding Electrodes, Welding Wires, Welding Cables and Welding Accessories.

MET-WELD was established in the year 1982 as a proprietary company. It is situated in Gujarat (India) at A/2, Shubh-Labh Estate, B/h. Laxmi Ice Factory, Maheshwari Mill Road, Tawdipura, Shahibaug, Ahmedabad-380004. The company is managed by well qualified and experienced persons.

MANUFACTURER OF:-

Welding Transformers, DC Welding Rectifiers, Co2 MIG/MAG Welding Machines, Submerged Arc Welding (SAW) Machines, Electrodes Drying Ovens, etc.

AGENCIES OF:-

IGBT Controlled Welding Inverters, Welding Electrodes, Welding Wires, Welding Cables And Safety Accessories.

QUALITY POLICY:-

Our commitment to quality means to provide products and sales after services, which consistently meet or exceed customer's expectation and thus be a leader in the market we serve. We also provide continuous improvement of type, range and quality as per requirement of customers.

MET-WELD also boasts of skilled man power and competitive infrastructure.

OUR ASSOCIATES:-

SHREEJI SALES CORPORATION

YOGI TECHNO WELD

YOGI SALES CORPORATION

OUR PRODUCTS ARE USED BY FOLLOWING SECTORS:-

Most Of All Heavy Fabrication Industries

Chemical Industries

Pipe Line Projects

Thermal Power Unit

Cement Industries

State Transport & Bus Body Builders

Heavy Rolling Mills

Ship Building Industries

Automobile Industries

Government & Semi Government Sectors

SERVICES PROVIDE:-

WE ALSO PROVIDE WELDING RECTIFIERS & DG SETS ON HIRE BASE.WE ARE ALSO UNDERTAKING SERVICES OF ANY TYPE OF WELDING EQUIPMENTS.

Address:

A-2, Shubh-Labh Estate

B/h, Laxmi lce Factory,

Maheshwari Mill Road,

Tawdipura, Shahibaug,

Ahmedabad-380 004.

Gujarat (India)

Office Address:

106 & 107, Patel House,

Nr. Vinod Chamber,

O/s. Dariyapur Gate,

Ahmedabad - 380 001.

Tele Fax : +91-79-22174927

Mobile:

+91-9898013007

+91-9998999589

E-Mail:

info@metweld.in

metweld3@yahoo.com

Web:

http://metweld.in

welding machine, welding machine manufacturers, welding equipment, welding equipment manufacturers, welding electrodes, welding electrodes manufacturers, inverter welding machine, welding rectifier, welding oven, welding transformer, submerged arc welding machine, mig welding machine, welding equipment hire, welding equipment repair, welding equipment rental, welding machine manufacturers in gujarat. For more Detail Please Visit us at http://www.metweld.in/

Recommended

JC-4200 WM Roof Waterproofing Membrane Welder

Roof waterproofing membrane welder is a new type hot air machine specially made for roof waterproofing membrane welding. By strong R&D engineering team, our machine equips advanced hot air heating technology, intelligent electronic temperature control and speed control system. According to practical material thickness especially for TPO or other poly waterproofing membrane, counterweight can be adjusted in order to modify welding pressure ro provide excellent welding performance, like uniform welding, no leakage, no wrinkles, high strength.

Geomembrane Overlap Wedge Welder

It adopts advanced hot wedge structure, With its high power, high speed and pressure, it welds 1.0mm – 3.0mm thickness hot melting materials such as HDPE, LDPE, PVC, EVA, ECB, PP and others This machine is specially designed for water conservancy, aquaculture, landfills, chemical mining, sewage treatment, roof constructions and other waterproofing projects.

Geomembrane Welding Machine

It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on.

JC-tool.com

IRJET- Design and Analysis of Friction Stir Welding using Dissimilar Alloys (...

https://www.irjet.net/archives/V5/i4/IRJET-V5I427.pdf

IRJET-Study of Mechanical Properties of Friction Stir Welded Joint of Similar...

https://irjet.net/archives/V5/i6/IRJET-V5I6268.pdf

Met weld - Welding Machine Manufacturers - ahmedabad - gujarat - INDIA

Metweld - Leading Indian manufacturers and exporter of Welding Machine, Welding Electrodes, Welding Wires, Welding Cables and Welding Accessories.

MET-WELD was established in the year 1982 as a proprietary company. It is situated in Gujarat (India) at A/2, Shubh-Labh Estate, B/h. Laxmi Ice Factory, Maheshwari Mill Road, Tawdipura, Shahibaug, Ahmedabad-380004. The company is managed by well qualified and experienced persons.

MANUFACTURER OF:-

Welding Transformers, DC Welding Rectifiers, Co2 MIG/MAG Welding Machines, Submerged Arc Welding (SAW) Machines, Electrodes Drying Ovens, etc.

AGENCIES OF:-

IGBT Controlled Welding Inverters, Welding Electrodes, Welding Wires, Welding Cables And Safety Accessories.

QUALITY POLICY:-

Our commitment to quality means to provide products and sales after services, which consistently meet or exceed customer's expectation and thus be a leader in the market we serve. We also provide continuous improvement of type, range and quality as per requirement of customers.

MET-WELD also boasts of skilled man power and competitive infrastructure.

OUR ASSOCIATES:-

SHREEJI SALES CORPORATION

YOGI TECHNO WELD

YOGI SALES CORPORATION

OUR PRODUCTS ARE USED BY FOLLOWING SECTORS:-

Most Of All Heavy Fabrication Industries

Chemical Industries

Pipe Line Projects

Thermal Power Unit

Cement Industries

State Transport & Bus Body Builders

Heavy Rolling Mills

Ship Building Industries

Automobile Industries

Government & Semi Government Sectors

SERVICES PROVIDE:-

WE ALSO PROVIDE WELDING RECTIFIERS & DG SETS ON HIRE BASE.WE ARE ALSO UNDERTAKING SERVICES OF ANY TYPE OF WELDING EQUIPMENTS.

Address:

A-2, Shubh-Labh Estate

B/h, Laxmi lce Factory,

Maheshwari Mill Road,

Tawdipura, Shahibaug,

Ahmedabad-380 004.

Gujarat (India)

Office Address:

106 & 107, Patel House,

Nr. Vinod Chamber,

O/s. Dariyapur Gate,

Ahmedabad - 380 001.

Tele Fax : +91-79-22174927

Mobile:

+91-9898013007

+91-9998999589

E-Mail:

info@metweld.in

metweld3@yahoo.com

Web:

http://metweld.in

welding machine, welding machine manufacturers, welding equipment, welding equipment manufacturers, welding electrodes, welding electrodes manufacturers, inverter welding machine, welding rectifier, welding oven, welding transformer, submerged arc welding machine, mig welding machine, welding equipment hire, welding equipment repair, welding equipment rental, welding machine manufacturers in gujarat. For more Detail Please Visit us at http://www.metweld.in/

JC-4200-PM Banner & Tarpaulin Welder

The welder equips advanced heating system. It is handy, stable and easy to be operated, which is suitable for advertising banner seaming. It could be used as assistant tools for hem or pocket welding.

Banner Welding Equipment

It can be applicable for welding PVC-P、PE、TPO、ECB、CSPE、EPDM、PVDF and other

Coated fabric covering, foil and homogeneous or coating sealing film and PE coating

fabric

JC-1800-DTM Geomembrane Wedge Welder

Applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and PVC, HDPE, EVA, PP.

Plastic Extrusion Welder

Plastic Extrusion Welder Extruding plastic gun is a new type of hot air welder which is imported foreign advanced technology, well-developed. Extrusion Welder major components (hot air gun and drive motor) are made of imported brand-name accessories, stable performance, long service life; They are two independent systems, one is for preheating raw material, another is for welding rod extrusion. Reasonable structure, convenient operation, continuous welding, high working efficiency, powerful extrusion, to make the weld strength is greatly improved. It is the ideal product for a variety of thermoplastic welding processing.

Experimental study of double point cutting tool on chip – tool interface temp...

Abstract A special type of a tool is designed and made to have two cutting points for turning long workpieces and it may be termed as the double point cutting tool. The double point cutting tool has two cutting points which has the height difference of 0.5 mm and the distance between them is 6 mm. So that when the first cutting point takes 0.5 mm depth of cut and next to that the second cutting point also takes 0.5 mm depth of cut as the tool proceeds for turning. Hence the total machining time is reduced considerably. Chip – Tool Interface Temperature takes very important role in metal cutting which decides the dimensional accuracy, mechanical properties of the workpiece and the tool life. Investigation on Chip – Tool Interface Temperature in HSS Double Point Cutting Tool during turning of Mild Steel for different cutting conditions is presented in this Research article. Keywords: double point cutting tool, machining time, chip – tool interface temperature, dimensional accuracy, mechanical properties of the work piece, tool life

Hot Knife Cutter JC-tool.com

Suitable for fabrics, packing, advertising, clothing, outdoor equipment, mechatronics, vehicle, furniture, decoration, and construction

MAHABIR - Double Side Planner Manual

MAHABIR INDUSTRIES

CONTACT : sales@mahabirindustries.com

Step into the world of woodworking excellence with Mahabir Wood Working Machines. For decades, these machines have stood as a symbol of unparalleled craftsmanship and innovation, earning the trust and admiration of woodworking enthusiasts and professionals alike.

Designed with precision and engineered to perfection, Mahabir Wood Working Machines offer a wide range of tools that cater to every woodworking need. From powerful table saws to versatile routers, robust planers to efficient sanders, each machine is built to withstand the rigors of daily use while delivering consistently high-quality results.

One of the key reasons behind the popularity of Mahabir Wood Working Machines is their commitment to quality and durability. Using premium materials and cutting-edge technology, these machines are built to last, ensuring years of reliable service and smooth operation.

Whether you are a seasoned woodworker or just starting your woodworking journey, Mahabir machines are designed to empower you with precision and ease. The intuitive controls and user-friendly features make them accessible to all skill levels, allowing you to bring your creative visions to life.

Emphasizing safety and efficiency, each Mahabir Wood Working Machine undergoes rigorous testing to meet industry standards, providing you with peace of mind while you work on your projects.

Investing in a Mahabir Wood Working Machine means investing in the future of your woodworking endeavors. Join the ranks of satisfied users who have discovered the joy of crafting with precision and efficiency, courtesy of Mahabir Wood Working Machines - a true partner in your woodworking journey.

EDDYCON C eddy current flaw detector

ULTRACON-SERVICE LLC pressents

the EDDYCON C eddy current flaw detector. It is used for detection of surface cracks in various parts, cracks in holes and multilayered structures, surface and subsurface corrosion.

Eddy current is an acceptable method for detecting conductivity of non-ferrous materials and coating thickness.

For further information, please visit our website at www.ultracon-service.com.ua

Custom roll forming machine

Custom roll forming machine Superda design for metal profiles, metal channel, steel door, cable tray, floor deck, roof panel, purlin profiles...

Understanding the welding process and troubleshooting.

This Tutorial will help newbee to understand the welding process and its trouble which are easy to sort out during the production. Just follow the tutorial and boost your knowledge to understand the welding process.

IRJET - Design Procedure and Impact of Fixed Type Automation for Billet Loading

https://irjet.net/archives/V7/i3/IRJET-V7I3464.pdf

IRJET- Prediction of Angular Distortion in TIG Welded Stainless Steel 202 She...

https://www.irjet.net/archives/V6/i4/IRJET-V6I41343.pdf

Beam roll forming machine

Superda beam roll forming machine for logistic sy beam box, construction usinb beam, steel beam production, super design roll forming machine.

Trouble shooting a Miller welding machine

contains the practical steps to trouble shooting a welding machine

Cosmetic shop management system project report.pdf

Buying new cosmetic products is difficult. It can even be scary for those who have sensitive skin and are prone to skin trouble. The information needed to alleviate this problem is on the back of each product, but it's thought to interpret those ingredient lists unless you have a background in chemistry.

Instead of buying and hoping for the best, we can use data science to help us predict which products may be good fits for us. It includes various function programs to do the above mentioned tasks.

Data file handling has been effectively used in the program.

The automated cosmetic shop management system should deal with the automation of general workflow and administration process of the shop. The main processes of the system focus on customer's request where the system is able to search the most appropriate products and deliver it to the customers. It should help the employees to quickly identify the list of cosmetic product that have reached the minimum quantity and also keep a track of expired date for each cosmetic product. It should help the employees to find the rack number in which the product is placed.It is also Faster and more efficient way.

Forklift Classes Overview by Intella Parts

Discover the different forklift classes and their specific applications. Learn how to choose the right forklift for your needs to ensure safety, efficiency, and compliance in your operations.

For more technical information, visit our website https://intellaparts.com

More Related Content

Similar to Geomembrane Welding Machine

JC-4200-PM Banner & Tarpaulin Welder

The welder equips advanced heating system. It is handy, stable and easy to be operated, which is suitable for advertising banner seaming. It could be used as assistant tools for hem or pocket welding.

Banner Welding Equipment

It can be applicable for welding PVC-P、PE、TPO、ECB、CSPE、EPDM、PVDF and other

Coated fabric covering, foil and homogeneous or coating sealing film and PE coating

fabric

JC-1800-DTM Geomembrane Wedge Welder

Applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and PVC, HDPE, EVA, PP.

Plastic Extrusion Welder

Plastic Extrusion Welder Extruding plastic gun is a new type of hot air welder which is imported foreign advanced technology, well-developed. Extrusion Welder major components (hot air gun and drive motor) are made of imported brand-name accessories, stable performance, long service life; They are two independent systems, one is for preheating raw material, another is for welding rod extrusion. Reasonable structure, convenient operation, continuous welding, high working efficiency, powerful extrusion, to make the weld strength is greatly improved. It is the ideal product for a variety of thermoplastic welding processing.

Experimental study of double point cutting tool on chip – tool interface temp...

Abstract A special type of a tool is designed and made to have two cutting points for turning long workpieces and it may be termed as the double point cutting tool. The double point cutting tool has two cutting points which has the height difference of 0.5 mm and the distance between them is 6 mm. So that when the first cutting point takes 0.5 mm depth of cut and next to that the second cutting point also takes 0.5 mm depth of cut as the tool proceeds for turning. Hence the total machining time is reduced considerably. Chip – Tool Interface Temperature takes very important role in metal cutting which decides the dimensional accuracy, mechanical properties of the workpiece and the tool life. Investigation on Chip – Tool Interface Temperature in HSS Double Point Cutting Tool during turning of Mild Steel for different cutting conditions is presented in this Research article. Keywords: double point cutting tool, machining time, chip – tool interface temperature, dimensional accuracy, mechanical properties of the work piece, tool life

Hot Knife Cutter JC-tool.com

Suitable for fabrics, packing, advertising, clothing, outdoor equipment, mechatronics, vehicle, furniture, decoration, and construction

MAHABIR - Double Side Planner Manual

MAHABIR INDUSTRIES

CONTACT : sales@mahabirindustries.com

Step into the world of woodworking excellence with Mahabir Wood Working Machines. For decades, these machines have stood as a symbol of unparalleled craftsmanship and innovation, earning the trust and admiration of woodworking enthusiasts and professionals alike.

Designed with precision and engineered to perfection, Mahabir Wood Working Machines offer a wide range of tools that cater to every woodworking need. From powerful table saws to versatile routers, robust planers to efficient sanders, each machine is built to withstand the rigors of daily use while delivering consistently high-quality results.

One of the key reasons behind the popularity of Mahabir Wood Working Machines is their commitment to quality and durability. Using premium materials and cutting-edge technology, these machines are built to last, ensuring years of reliable service and smooth operation.

Whether you are a seasoned woodworker or just starting your woodworking journey, Mahabir machines are designed to empower you with precision and ease. The intuitive controls and user-friendly features make them accessible to all skill levels, allowing you to bring your creative visions to life.

Emphasizing safety and efficiency, each Mahabir Wood Working Machine undergoes rigorous testing to meet industry standards, providing you with peace of mind while you work on your projects.

Investing in a Mahabir Wood Working Machine means investing in the future of your woodworking endeavors. Join the ranks of satisfied users who have discovered the joy of crafting with precision and efficiency, courtesy of Mahabir Wood Working Machines - a true partner in your woodworking journey.

EDDYCON C eddy current flaw detector

ULTRACON-SERVICE LLC pressents

the EDDYCON C eddy current flaw detector. It is used for detection of surface cracks in various parts, cracks in holes and multilayered structures, surface and subsurface corrosion.

Eddy current is an acceptable method for detecting conductivity of non-ferrous materials and coating thickness.

For further information, please visit our website at www.ultracon-service.com.ua

Custom roll forming machine

Custom roll forming machine Superda design for metal profiles, metal channel, steel door, cable tray, floor deck, roof panel, purlin profiles...

Understanding the welding process and troubleshooting.

This Tutorial will help newbee to understand the welding process and its trouble which are easy to sort out during the production. Just follow the tutorial and boost your knowledge to understand the welding process.

IRJET - Design Procedure and Impact of Fixed Type Automation for Billet Loading

https://irjet.net/archives/V7/i3/IRJET-V7I3464.pdf

IRJET- Prediction of Angular Distortion in TIG Welded Stainless Steel 202 She...

https://www.irjet.net/archives/V6/i4/IRJET-V6I41343.pdf

Beam roll forming machine

Superda beam roll forming machine for logistic sy beam box, construction usinb beam, steel beam production, super design roll forming machine.

Trouble shooting a Miller welding machine

contains the practical steps to trouble shooting a welding machine

Similar to Geomembrane Welding Machine (20)

Experimental study of double point cutting tool on chip – tool interface temp...

Experimental study of double point cutting tool on chip – tool interface temp...

Understanding the welding process and troubleshooting.

Understanding the welding process and troubleshooting.

IRJET - Design Procedure and Impact of Fixed Type Automation for Billet Loading

IRJET - Design Procedure and Impact of Fixed Type Automation for Billet Loading

IRJET- Prediction of Angular Distortion in TIG Welded Stainless Steel 202 She...

IRJET- Prediction of Angular Distortion in TIG Welded Stainless Steel 202 She...

Recently uploaded

Cosmetic shop management system project report.pdf

Buying new cosmetic products is difficult. It can even be scary for those who have sensitive skin and are prone to skin trouble. The information needed to alleviate this problem is on the back of each product, but it's thought to interpret those ingredient lists unless you have a background in chemistry.

Instead of buying and hoping for the best, we can use data science to help us predict which products may be good fits for us. It includes various function programs to do the above mentioned tasks.

Data file handling has been effectively used in the program.

The automated cosmetic shop management system should deal with the automation of general workflow and administration process of the shop. The main processes of the system focus on customer's request where the system is able to search the most appropriate products and deliver it to the customers. It should help the employees to quickly identify the list of cosmetic product that have reached the minimum quantity and also keep a track of expired date for each cosmetic product. It should help the employees to find the rack number in which the product is placed.It is also Faster and more efficient way.

Forklift Classes Overview by Intella Parts

Discover the different forklift classes and their specific applications. Learn how to choose the right forklift for your needs to ensure safety, efficiency, and compliance in your operations.

For more technical information, visit our website https://intellaparts.com

Water Industry Process Automation and Control Monthly - May 2024.pdf

Water Industry Process Automation and Control Monthly - May 2024.pdfWater Industry Process Automation & Control

Welcome to WIPAC Monthly the magazine brought to you by the LinkedIn Group Water Industry Process Automation & Control.

In this month's edition, along with this month's industry news to celebrate the 13 years since the group was created we have articles including

A case study of the used of Advanced Process Control at the Wastewater Treatment works at Lleida in Spain

A look back on an article on smart wastewater networks in order to see how the industry has measured up in the interim around the adoption of Digital Transformation in the Water Industry.一比一原版(SFU毕业证)西蒙菲莎大学毕业证成绩单如何办理

SFU毕业证原版定制【微信:176555708】【西蒙菲莎大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

J.Yang, ICLR 2024, MLILAB, KAIST AI.pdf

Language-Interfaced Tabular Oversampling Via Progressive Imputation And Self Autentication

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Advancements in technology unveil a myriad of electrical and electronic breakthroughs geared towards efficiently harnessing limited resources to meet human energy demands. The optimization of hybrid solar PV panels and pumped hydro energy supply systems plays a pivotal role in utilizing natural resources effectively. This initiative not only benefits humanity but also fosters environmental sustainability. The study investigated the design optimization of these hybrid systems, focusing on understanding solar radiation patterns, identifying geographical influences on solar radiation, formulating a mathematical model for system optimization, and determining the optimal configuration of PV panels and pumped hydro storage. Through a comparative analysis approach and eight weeks of data collection, the study addressed key research questions related to solar radiation patterns and optimal system design. The findings highlighted regions with heightened solar radiation levels, showcasing substantial potential for power generation and emphasizing the system's efficiency. Optimizing system design significantly boosted power generation, promoted renewable energy utilization, and enhanced energy storage capacity. The study underscored the benefits of optimizing hybrid solar PV panels and pumped hydro energy supply systems for sustainable energy usage. Optimizing the design of solar PV panels and pumped hydro energy supply systems as examined across diverse climatic conditions in a developing country, not only enhances power generation but also improves the integration of renewable energy sources and boosts energy storage capacities, particularly beneficial for less economically prosperous regions. Additionally, the study provides valuable insights for advancing energy research in economically viable areas. Recommendations included conducting site-specific assessments, utilizing advanced modeling tools, implementing regular maintenance protocols, and enhancing communication among system components.

Automobile Management System Project Report.pdf

The proposed project is developed to manage the automobile in the automobile dealer company. The main module in this project is login, automobile management, customer management, sales, complaints and reports. The first module is the login. The automobile showroom owner should login to the project for usage. The username and password are verified and if it is correct, next form opens. If the username and password are not correct, it shows the error message.

When a customer search for a automobile, if the automobile is available, they will be taken to a page that shows the details of the automobile including automobile name, automobile ID, quantity, price etc. “Automobile Management System” is useful for maintaining automobiles, customers effectively and hence helps for establishing good relation between customer and automobile organization. It contains various customized modules for effectively maintaining automobiles and stock information accurately and safely.

When the automobile is sold to the customer, stock will be reduced automatically. When a new purchase is made, stock will be increased automatically. While selecting automobiles for sale, the proposed software will automatically check for total number of available stock of that particular item, if the total stock of that particular item is less than 5, software will notify the user to purchase the particular item.

Also when the user tries to sale items which are not in stock, the system will prompt the user that the stock is not enough. Customers of this system can search for a automobile; can purchase a automobile easily by selecting fast. On the other hand the stock of automobiles can be maintained perfectly by the automobile shop manager overcoming the drawbacks of existing system.

TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE

AIRCRAFT GENERAL

The Single Aisle is the most advanced family aircraft in service today, with fly-by-wire flight controls.

The A318, A319, A320 and A321 are twin-engine subsonic medium range aircraft.

The family offers a choice of engines

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Explore the innovative world of trenchless pipe repair with our comprehensive guide, "The Benefits and Techniques of Trenchless Pipe Repair." This document delves into the modern methods of repairing underground pipes without the need for extensive excavation, highlighting the numerous advantages and the latest techniques used in the industry.

Learn about the cost savings, reduced environmental impact, and minimal disruption associated with trenchless technology. Discover detailed explanations of popular techniques such as pipe bursting, cured-in-place pipe (CIPP) lining, and directional drilling. Understand how these methods can be applied to various types of infrastructure, from residential plumbing to large-scale municipal systems.

Ideal for homeowners, contractors, engineers, and anyone interested in modern plumbing solutions, this guide provides valuable insights into why trenchless pipe repair is becoming the preferred choice for pipe rehabilitation. Stay informed about the latest advancements and best practices in the field.

Halogenation process of chemical process industries

This presentation is about nitration process of industries, unit processes of chemical engineering.

Student information management system project report ii.pdf

Our project explains about the student management. This project mainly explains the various actions related to student details. This project shows some ease in adding, editing and deleting the student details. It also provides a less time consuming process for viewing, adding, editing and deleting the marks of the students.

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...Amil Baba Dawood bangali

Contact with Dawood Bhai Just call on +92322-6382012 and we'll help you. We'll solve all your problems within 12 to 24 hours and with 101% guarantee and with astrology systematic. If you want to take any personal or professional advice then also you can call us on +92322-6382012 , ONLINE LOVE PROBLEM & Other all types of Daily Life Problem's.Then CALL or WHATSAPP us on +92322-6382012 and Get all these problems solutions here by Amil Baba DAWOOD BANGALI

#vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore#blackmagicformarriage #aamilbaba #kalajadu #kalailam #taweez #wazifaexpert #jadumantar #vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore #blackmagicforlove #blackmagicformarriage #aamilbaba #kalajadu #kalailam #taweez #wazifaexpert #jadumantar #vashikaranspecialist #astrologer #palmistry #amliyaat #taweez #manpasandshadi #horoscope #spiritual #lovelife #lovespell #marriagespell#aamilbabainpakistan #amilbabainkarachi #powerfullblackmagicspell #kalajadumantarspecialist #realamilbaba #AmilbabainPakistan #astrologerincanada #astrologerindubai #lovespellsmaster #kalajaduspecialist #lovespellsthatwork #aamilbabainlahore #Amilbabainuk #amilbabainspain #amilbabaindubai #Amilbabainnorway #amilbabainkrachi #amilbabainlahore #amilbabaingujranwalan #amilbabainislamabad

Recently uploaded (20)

Cosmetic shop management system project report.pdf

Cosmetic shop management system project report.pdf

Water Industry Process Automation and Control Monthly - May 2024.pdf

Water Industry Process Automation and Control Monthly - May 2024.pdf

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

Hybrid optimization of pumped hydro system and solar- Engr. Abdul-Azeez.pdf

LIGA(E)11111111111111111111111111111111111111111.ppt

LIGA(E)11111111111111111111111111111111111111111.ppt

block diagram and signal flow graph representation

block diagram and signal flow graph representation

TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE

TECHNICAL TRAINING MANUAL GENERAL FAMILIARIZATION COURSE

The Benefits and Techniques of Trenchless Pipe Repair.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Halogenation process of chemical process industries

Halogenation process of chemical process industries

Student information management system project report ii.pdf

Student information management system project report ii.pdf

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

NO1 Uk best vashikaran specialist in delhi vashikaran baba near me online vas...

Geomembrane Welding Machine

- 1. JC MACHINERY & TOOLS INC. Quality We Trust _____________________________________________________________________ www.jc-tool.com info@jc-tool.com Geomembrane Wedge Welder JC-1800-ZTM User Manual

- 2. JC MACHINERY & TOOLS INC. Quality We Trust __________________________________________________________________ www.jc-tool.com info@jc-tool.com 1 i. Applications It can be applicable for welding PE、PVC、HDPE、EVA、PP and other hot melted materials. ii. Notice 1. Use with grounded 3-cords mains cable and socket (socket with 15A capacity. On the corresponding welder, phase L connected to live wire, N to zero line, phase ╧ to grounded protection line), plug will not be modified without prior permission. 2. Pressure roller will not engage on free running. 3. Don’t touch hot wedge when they are hot. They may cause burns. 4. The voltage rating stated on the welder must correspond to line/mains voltage (220V). The drop cable / wire with protective earthed conductors can only be used. 5. To ensure operator safety and reliable operation of equipment, the power supply must be installed power supply and leakage protection at the construction site. 6. It must be running at the correct use of manipulation of the operator, or they may cause a fire or explosion caused by high temperature. 7. Don’t use welder in the water, or on a muddy construction site, to avoid flooding, rain or moisture. 8. The circuit board and other components in the controller box may be charged, please don’t disassemble it without professional skills. 9. In normal work, the welding temperature generally does not exceed 400℃ (752℉). 10. Please preheat the welder about 30 minutes if it hasn’t be used for a long time or it is affected with damp. 11. The power of this welder is large. Please don’t heat it for long time to avoid excessive heating if it is in absence of welding or interval time is longer.

- 3. JC MACHINERY & TOOLS INC. Quality We Trust __________________________________________________________________ www.jc-tool.com info@jc-tool.com 2 iii. Technical Parameters Voltage 220 V Frequency 50 Hz power 1800 W Temperature 0~450℃ (32-842℉) Thickness of material 0.2~2 mm Welding speed 0.5~8 m/min Welding width 15*2, cavity 20 mm Overlap width 120 mm Size( L*W*H) 256*232*260 mm Weight 7.5 kg iv. Description 2 1 12 954 7 86 10 3

- 4. JC MACHINERY & TOOLS INC. Quality We Trust __________________________________________________________________ www.jc-tool.com info@jc-tool.com 3 1. Handle crip 6 Rack 11 Adjusting screw 2. Handle 7 Hot wedge 12 Controller box 3 Pressure handle 8 Lower pressing wheel 13 After creeping roller 4 Lower pressure roller 9 Upper pressing wheel 14 Adjusting screw of hot wedge 5 Upper pressure roller 10 Cam 15 Front creeping roller v. The Usage of Controller Panel ● Power ON/OFF ( 17 ) is for controlling the main power of the welder. ● Switch power ON/OFF ( 17 ), LCD display shows as Figure 1, the hot wedge is not heating in natural state. ● Press the bottom (18) and (19)at the same time, LCD display shows as Figure 2, the hot wedge start to heat until reach your setting temperature. ● Press the bottom (18) and (19) at the same time again, LCD display shows as Figure 1, the hot wedge is not heating in natural state. ● Run ON/OFF (22) is used to control walking and stop of the welder ● When the welder start to run, LCD display shows as Figure 3. 15 14 13

- 5. JC MACHINERY & TOOLS INC. Quality We Trust __________________________________________________________________ www.jc-tool.com info@jc-tool.com 4 vi. Welding Parameters Setting 1. Welding temperature setting: Using bottoms (18) Temperature setting knob ↑and (19) Temperature setting knob ↓ on the panel to set the required temperature. You can set the temperature according to the welding materials and the ambient temperature. LCD display will show the set temperature and the current actual temperature. 2. Welding speed setting: Using bottoms (20) Speed setting knob↑ and (21) Speed setting knob ↓on the panel to set the required speed according to the welding temperature. LCD display will show the set speed and the current actual speed. 3. Welding pressure setting: It can change the welding pressure by rotating the pressure adjusting nut (11). Clockwise to reduce the pressure, counterclockwise to increase the pressure. 4. Adjusting hot wedge: Loosen Adjusting screw of hot wedge (14), then you can move the hot wedge back and forth, lock the adjustment screw of hot wedge (14) after choosing the appropriate position. Figure 1 Figure 2 Figure 3 16 17 18 19 222120 23

- 6. JC MACHINERY & TOOLS INC. Quality We Trust __________________________________________________________________ www.jc-tool.com info@jc-tool.com 5 5. Memory function: The machine has a memory function of parameters, namely when you use the welder next time, the welder will automatically use the last set of parameters without having to re-set parameters. vii. Welding Process 1. Please lift the pressure handle (3) to separate the upper and down pressure roller (5、4), then plug the power and open the on power switch. 2. Setting the welding parameters according to the data of welding test. 3. Please wait the actual temperature value reaching the setting value. 4. Put the welder at the welding position and put the two prepared materials (one up and the other one down) into the machine. 5. Press the pressure handle (3) to make the upper and down pressure roller (5、4) in place. Then open the run ON/OFF (22), the machine would start walking and welding automatically. 6. To observe the relative position of the welding seam and the edge of the welded membrane at any time. It must be promptly corrected if there is deviation. 7. When the welder walks into the end of material, the pressures handle needs to be lifted to separate the upper and down pressure roller in time. 8. After completion of the welding work, press the buttons (18) and (19) on the panel to make the hot wedge to stop heating. 9. Turn off the power ON/OFF.

- 7. JC MACHINERY & TOOLS INC. Quality We Trust __________________________________________________________________ www.jc-tool.com info@jc-tool.com 6 viii. Fault Diagnosis and Solved Ways The fault performance Caused reasons Solved ways Motor cannot turn 1. no power on 2. fuse burns 3. speed circuit board burns 4. motor burns 1. check power state and connect power 2. change new fuse 3. change new speed circuit board 4. change new motor Hot wedge cannot heat or overheat Thermocouple is out of order Change new thermocouple IX. Routine Maintenance When the welder is not used, it should be cleaned the dirt and mud sand and other debris in the hot wedge or inside chain cover. And oil the whole welder, and then keep it in a dry place.