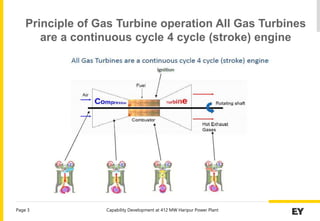

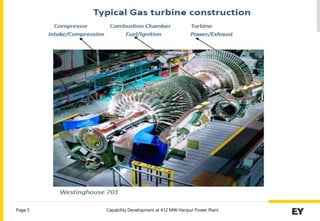

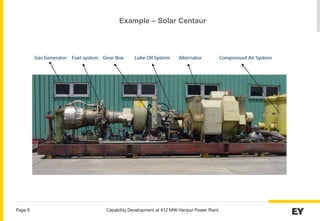

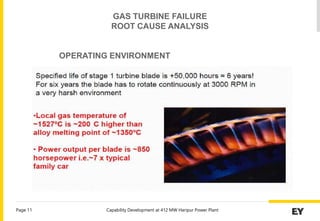

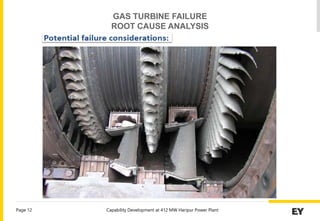

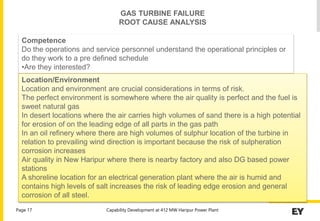

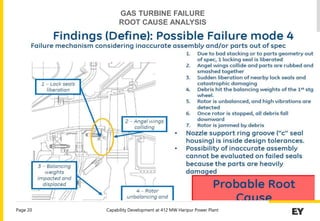

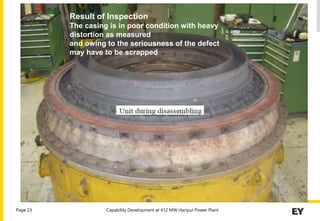

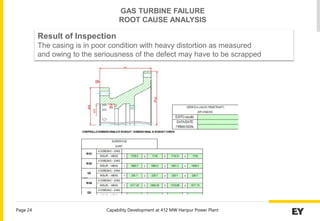

The presentation discusses gas turbine operation, types, failure considerations, and root cause analysis, focusing on the Haripur power plant's experience. Key topics include the mechanical principles of gas turbines, the impact of operational practices and environmental conditions on reliability, and examples of failure analysis and repair needs. The document emphasizes the importance of competent operations and effective maintenance in minimizing risks associated with gas turbine performance.