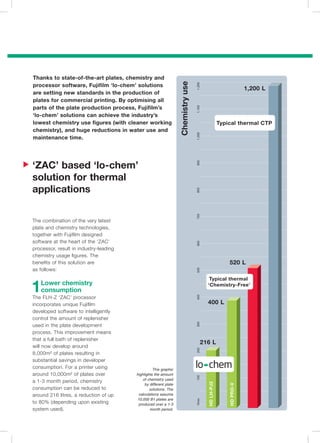

Fujifilm's low-chemistry plate production solutions are setting new standards in commercial printing. Their solutions can achieve the industry's lowest chemistry usage levels, significantly reduce water usage and maintenance time, and improve print quality. Specifically, Fujifilm's 'ZAC' processor uses intelligent software to control chemistry usage, allowing it to develop around 8,000 square meters of plates using only 216 liters of chemistry, an 80% reduction in chemicals. It also extends processor bath life and reduces cleaning time by over 40 hours per year.