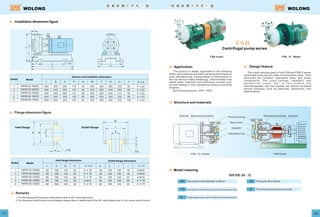

The FSB-30(d) series centrifugal pumps are versatile, suitable for various applications including auto manufacturing, metal metallurgy, and wastewater treatment, with a service temperature range of -20°C to 100°C. Made with fluoroplastic alloy, these compact pumps feature interchangeable parts, making them popular in industries like pesticides and electronics. The FSB models provide efficiency and reliability in transporting liquids, with specifications dedicated to different operational needs.