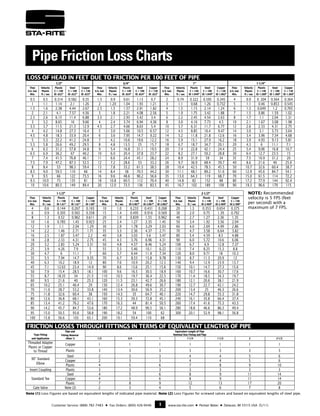

The document provides charts for calculating pipe friction loss based on pipe material, size, and flow rate. It gives equivalent lengths of common pipe fittings in terms of straight pipe lengths. It also provides charts listing the loss in head pressure per 100 feet of pipe for various pipe sizes, materials, and flow rates. The charts can be used to calculate pressure losses from friction in pipe systems.