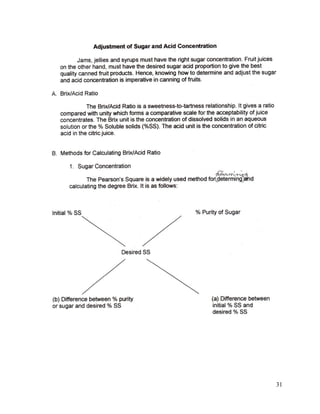

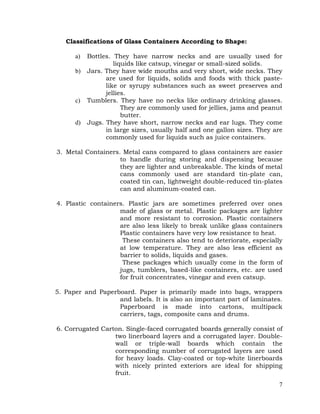

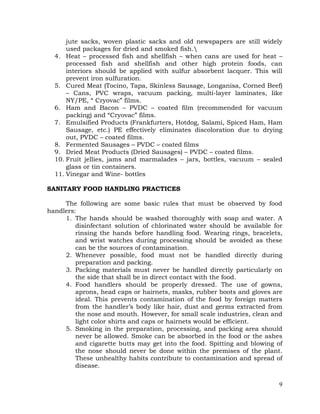

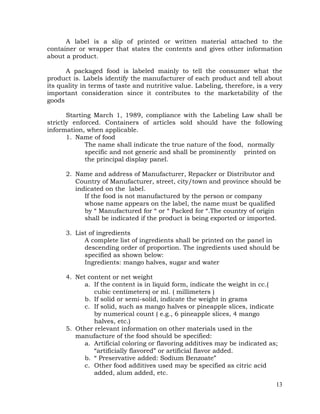

This document provides information about processing food by sugar concentration. It discusses preparing equipment, tools, and utensils. It describes sorting and grading raw materials like fruits and vegetables for making jellies, jams, marmalades, and preserves. It explains how to prepare different raw materials, including washing, slicing, boiling fruits to soften, and extracting juice. The key steps for jams are boiling pulp with sugar until thick. Marmalade involves suspending thin fruit or peel slices in a clear jelly.