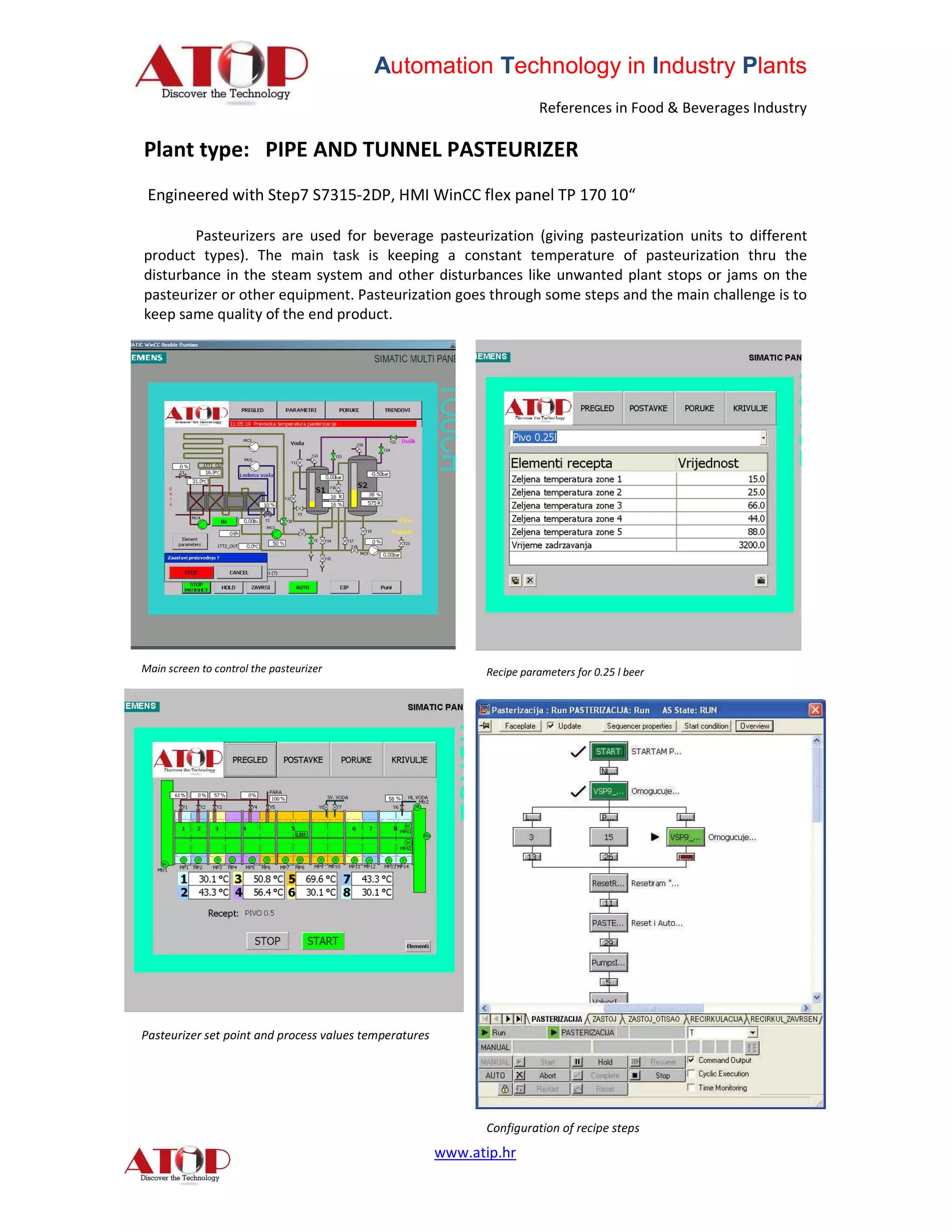

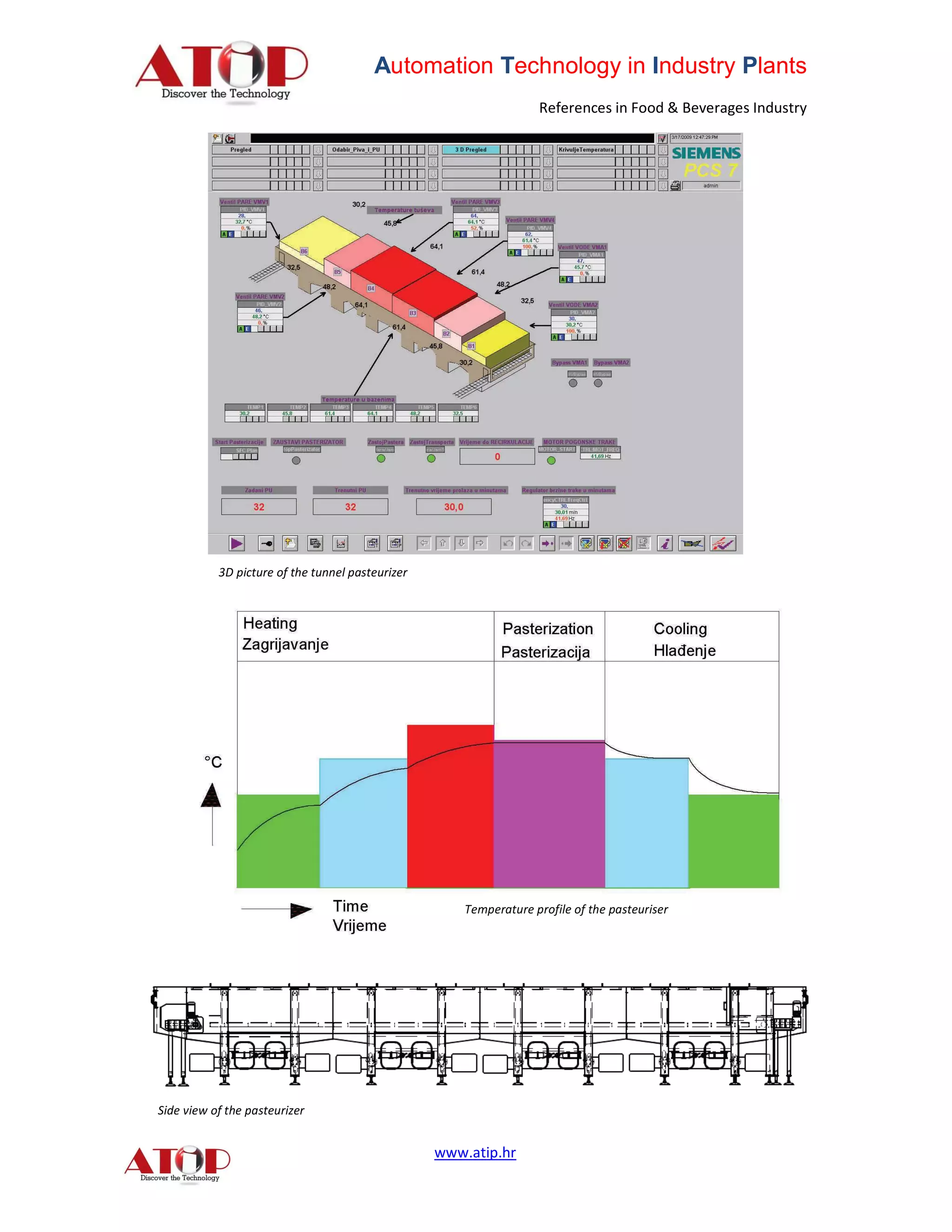

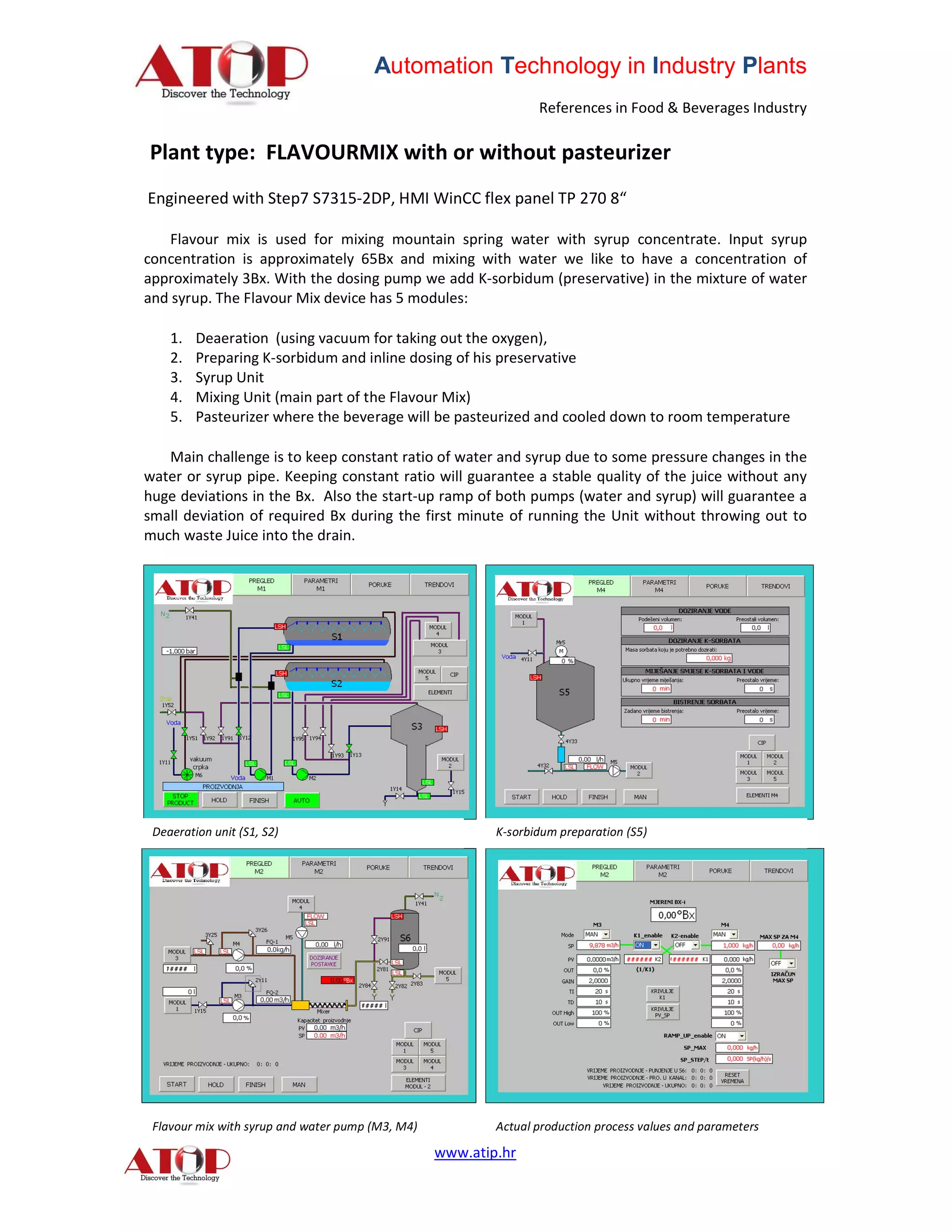

The document discusses automation technology used in food and beverage industry plants. It describes a CIP station engineered with Step7 and WinCC for cleaning processes. It also describes an evaporating plant with 5 evaporation stages used to reduce water content in juices. Main challenges are controlling temperature and flow rates. Additional aroma can be captured during evaporation. Finally, it discusses pipe and tunnel pasteurizers used to pasteurize beverages by maintaining constant temperature during processing steps despite disturbances.