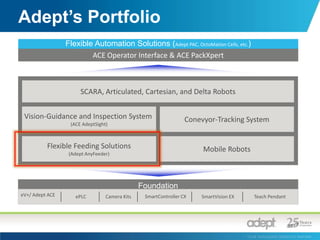

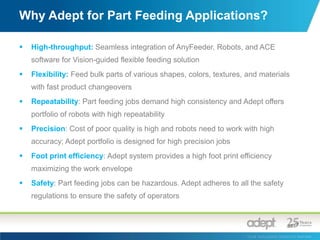

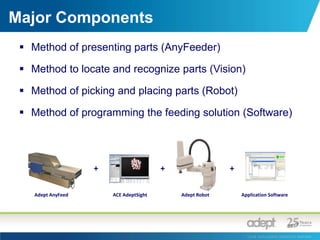

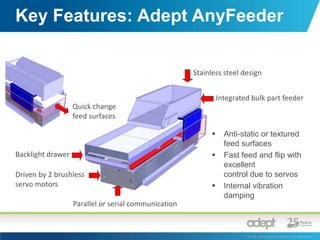

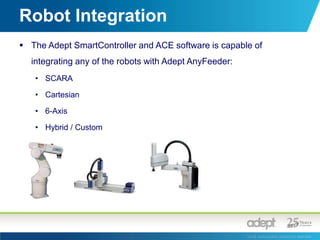

Adept Technology is a global company that provides flexible automation solutions including high-performance robots, vision systems, and part feeders to manufacturers. It has over 57,000 systems installed worldwide. One of its key products is the Adept AnyFeeder, which is a programmable part feeder that can handle a variety of parts quickly and easily through different feed surfaces and integration with Adept robots and vision systems. Adept's portfolio provides manufacturers flexibility and precision to manage production variability through an integrated solution.