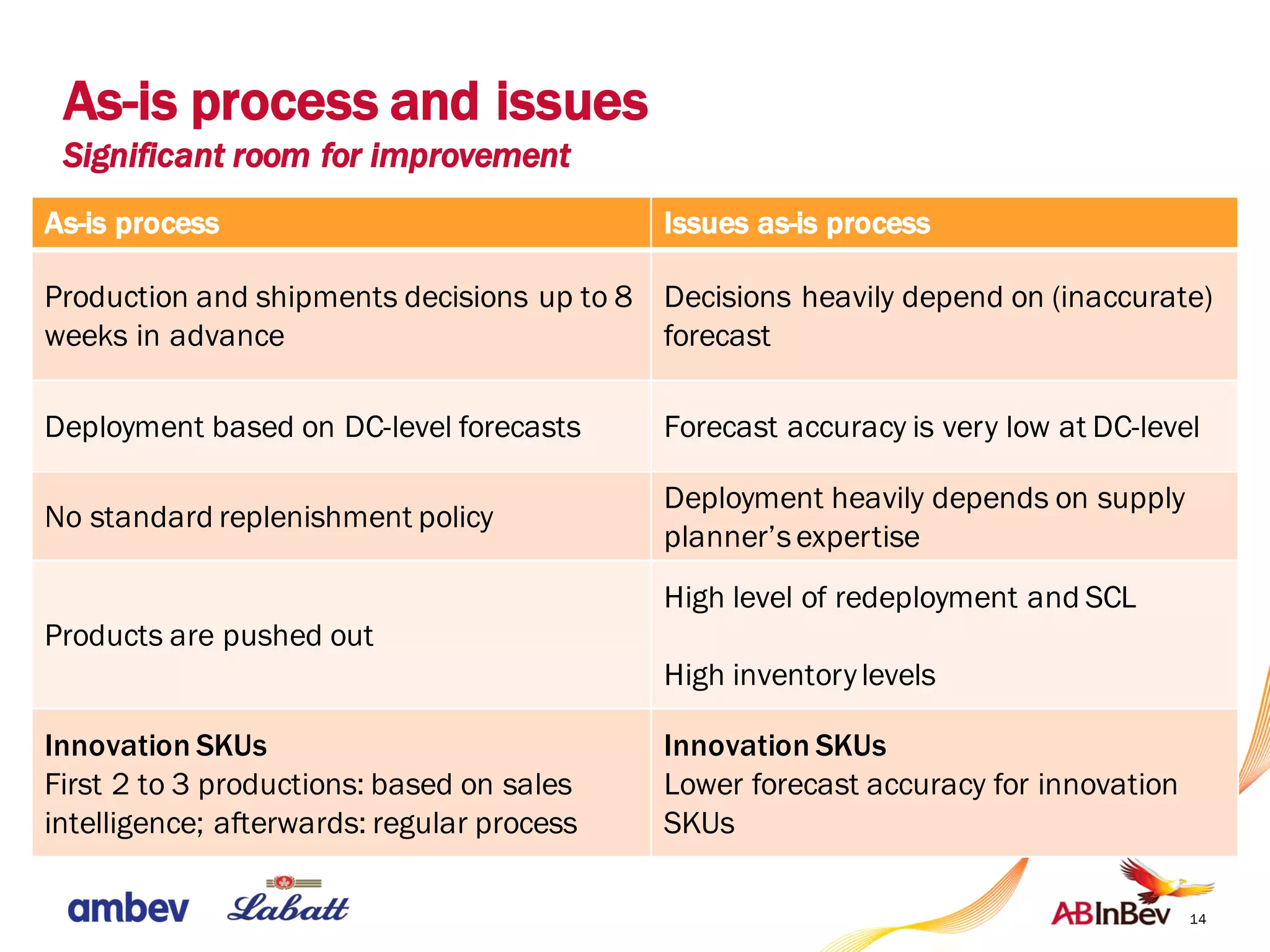

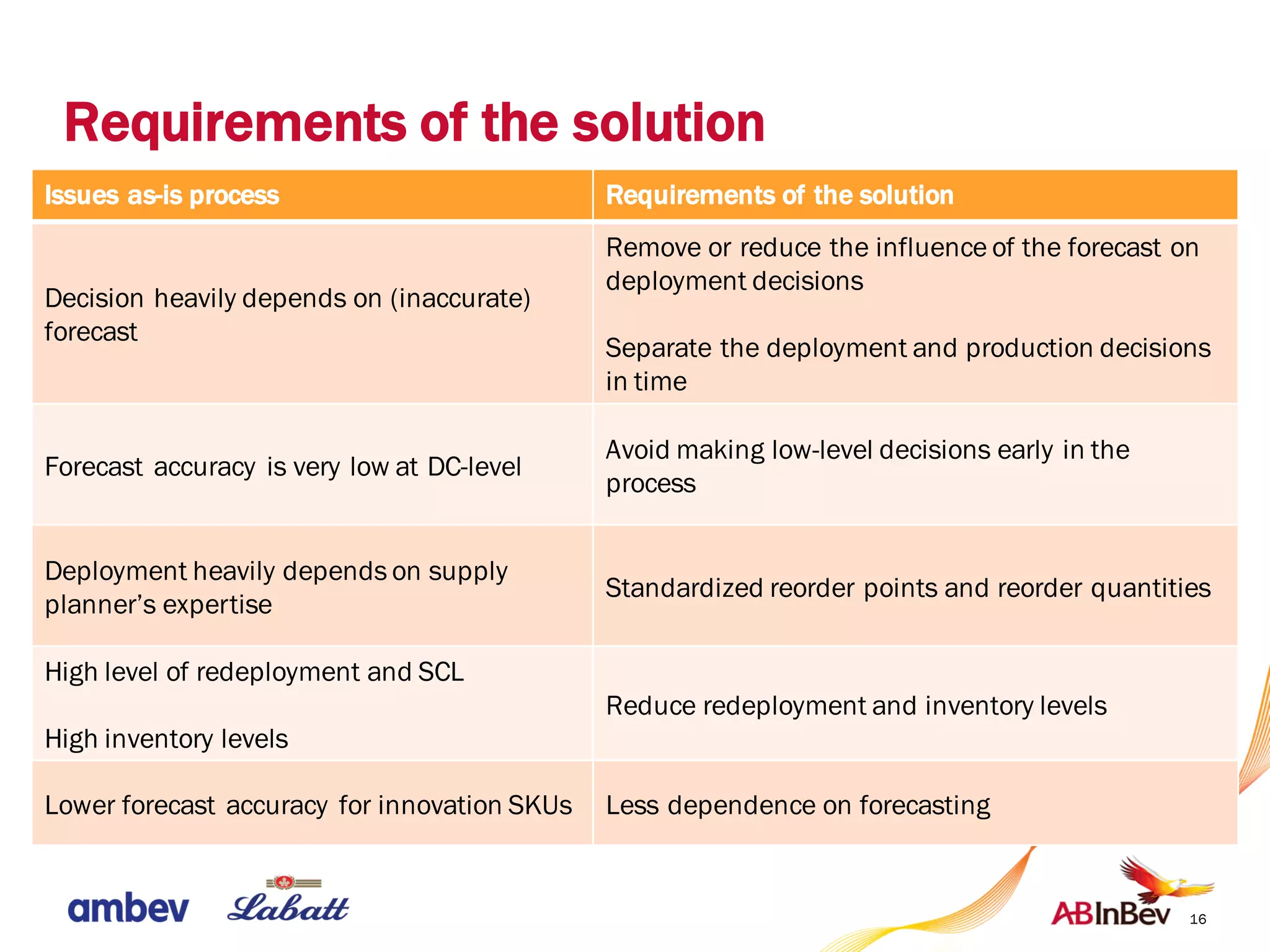

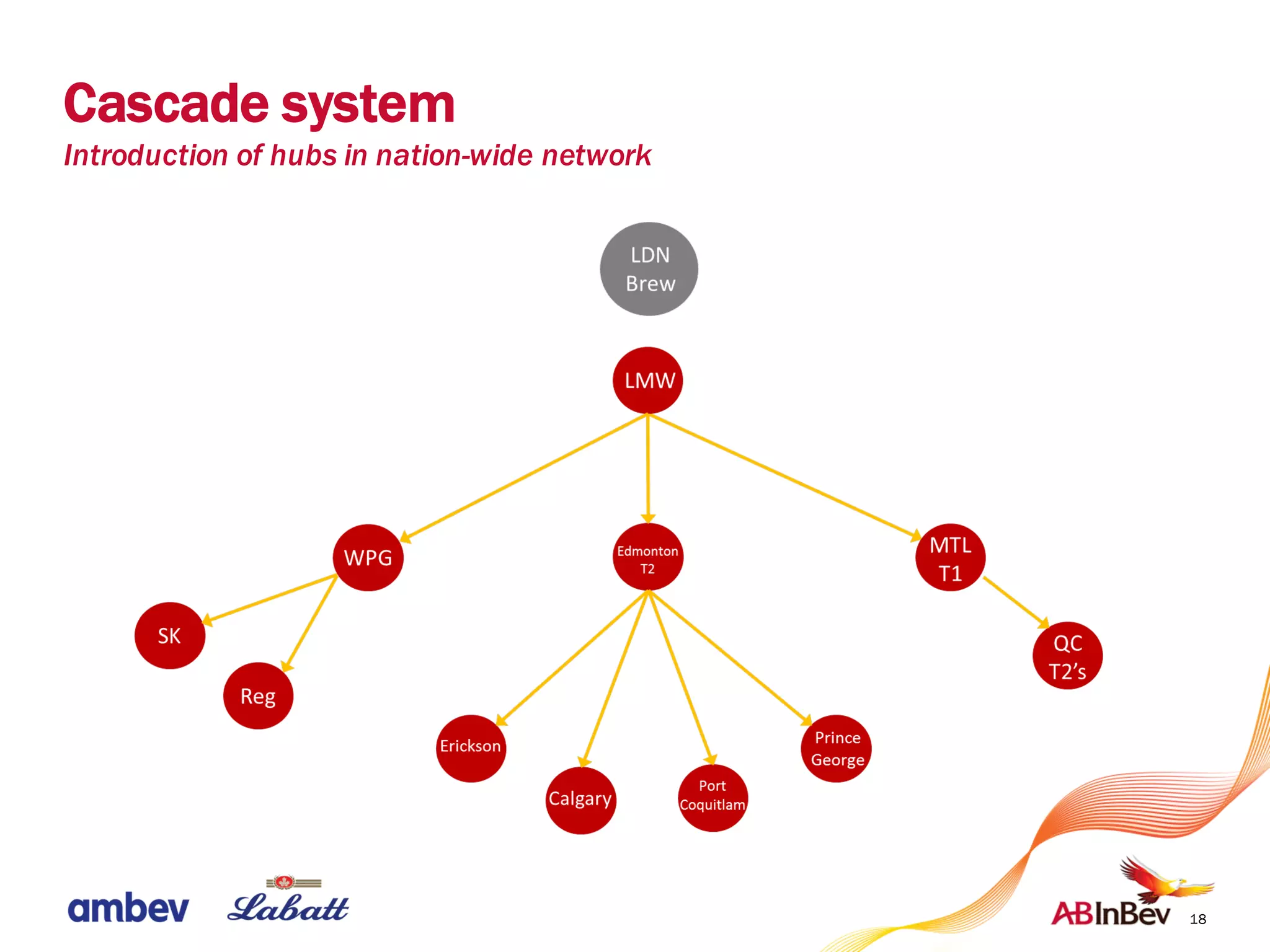

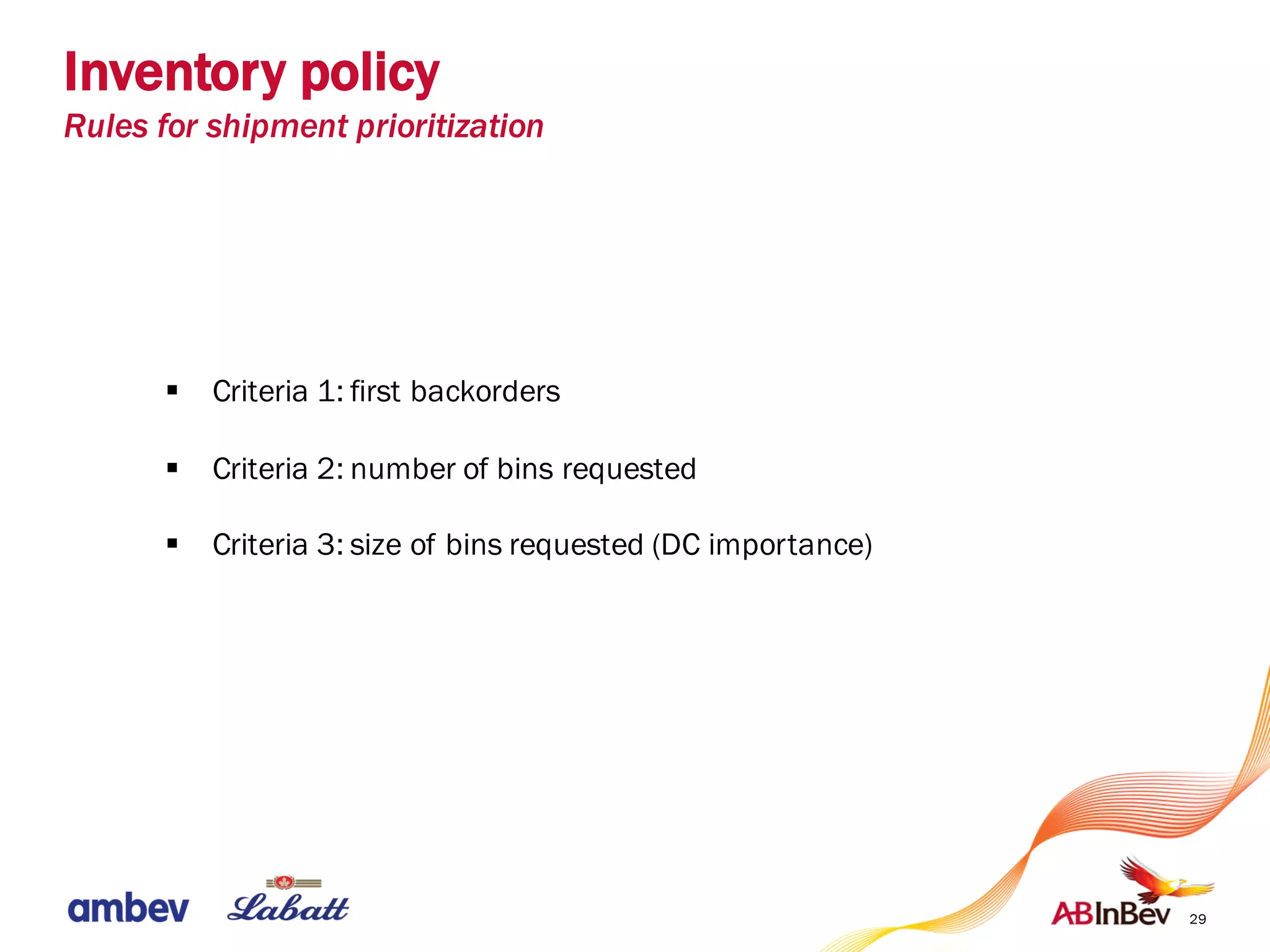

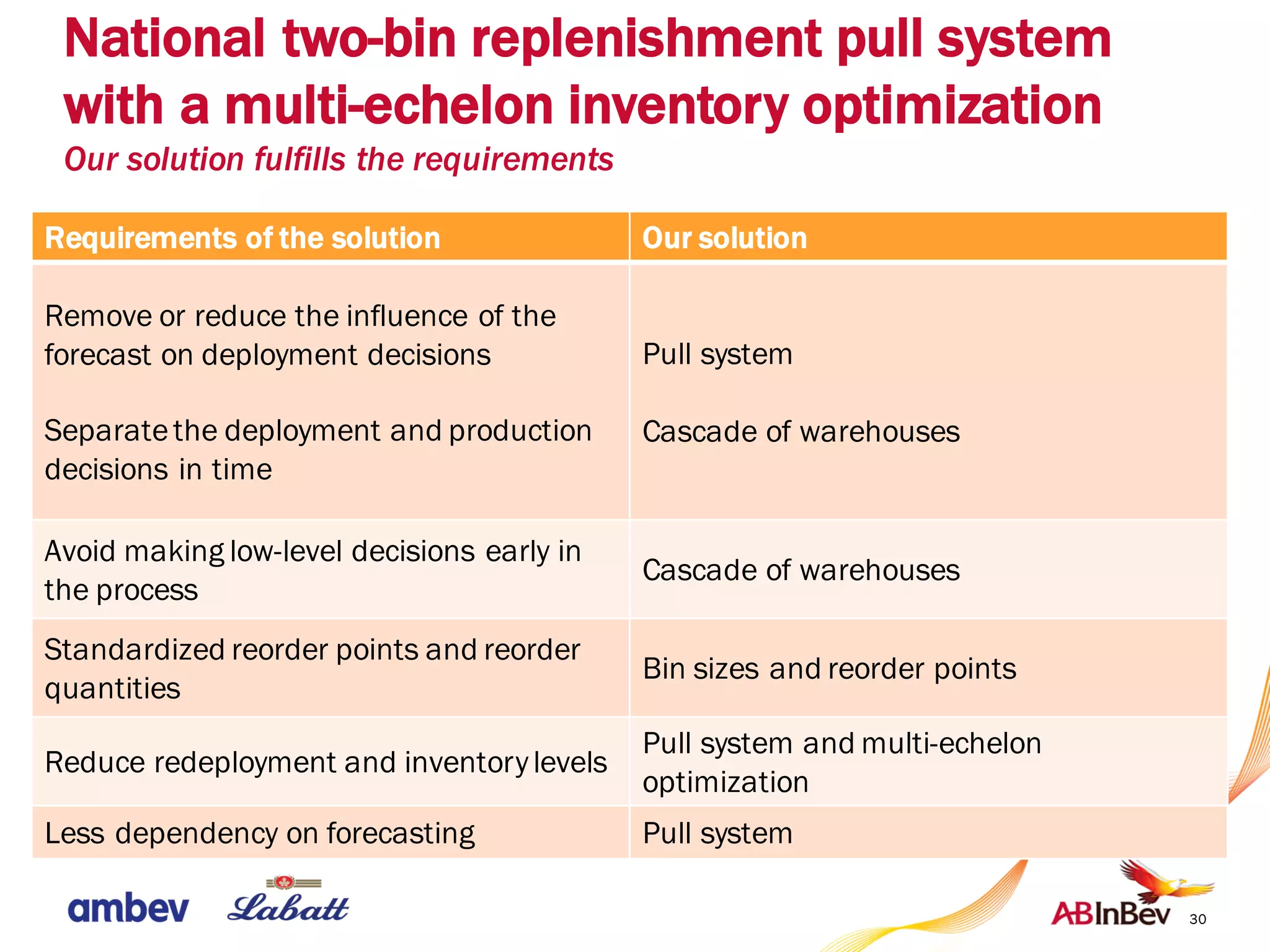

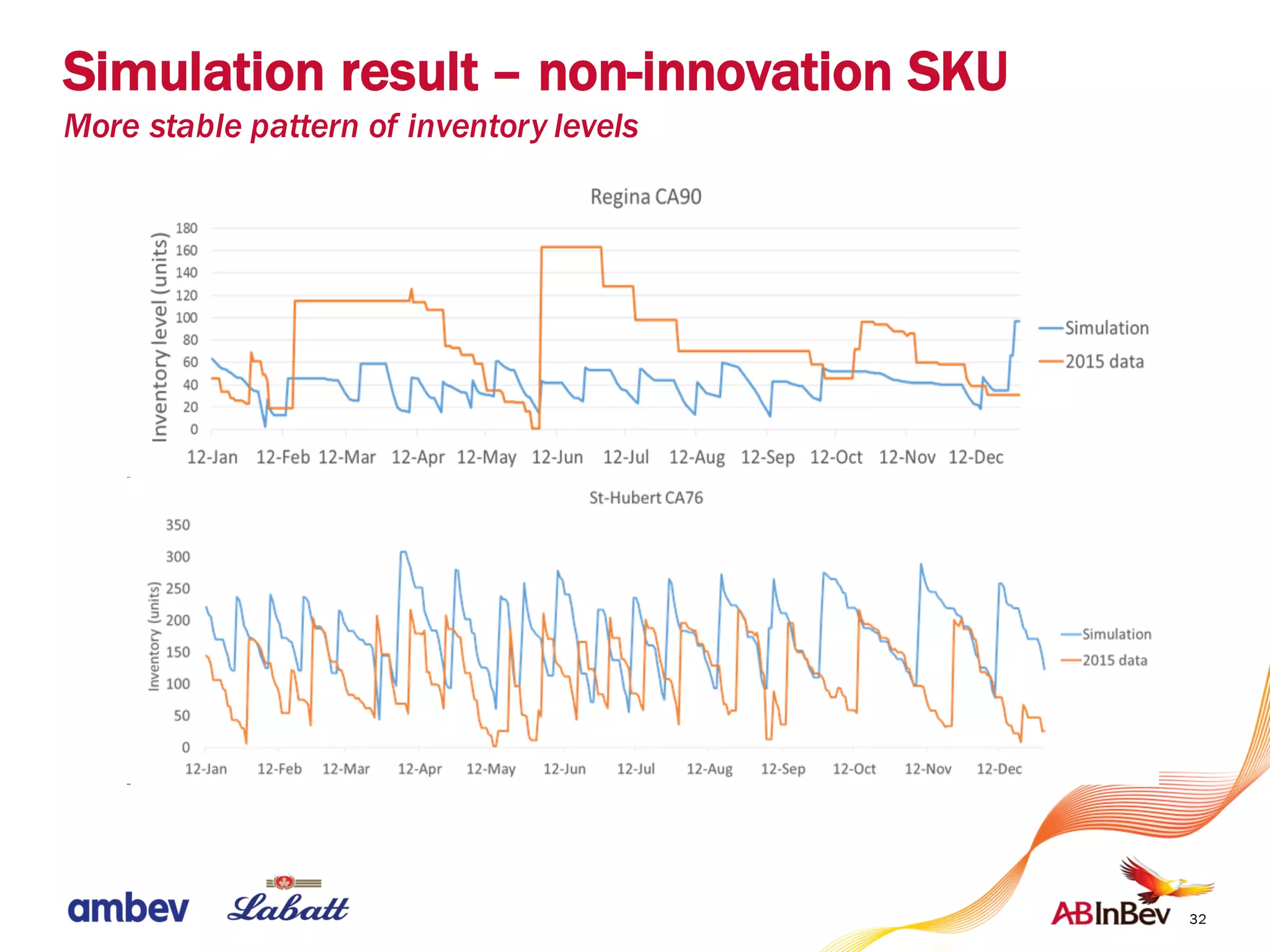

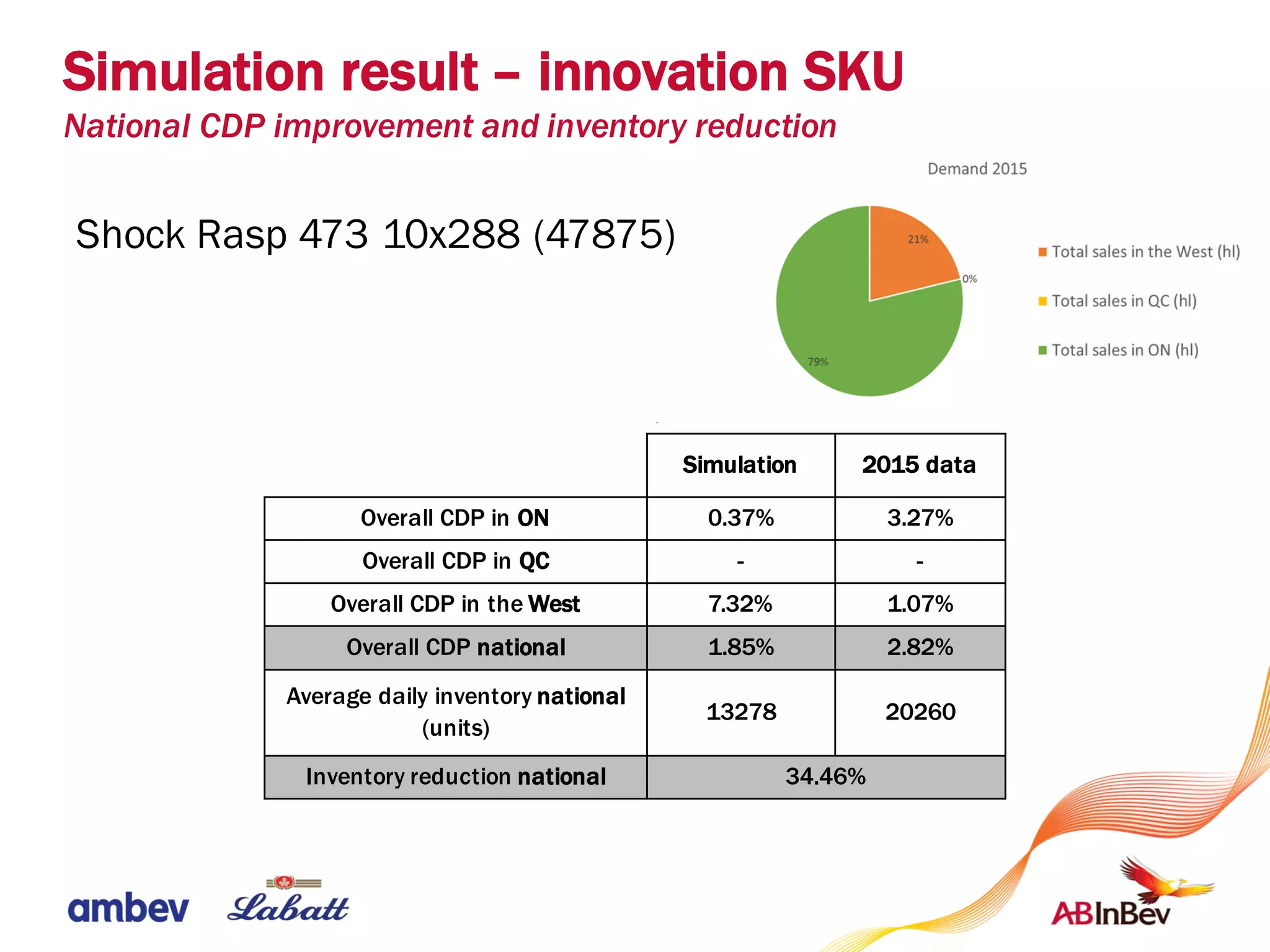

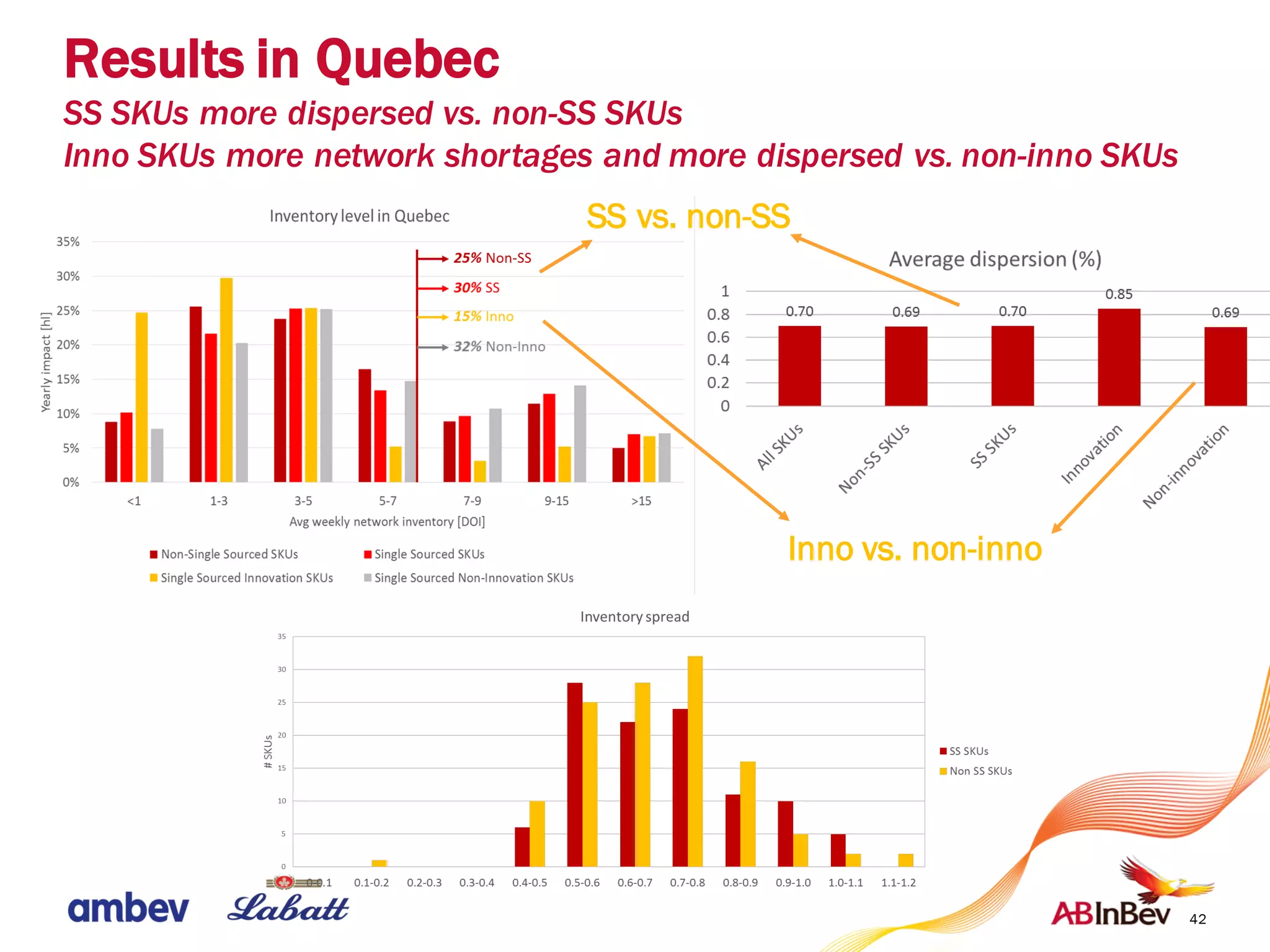

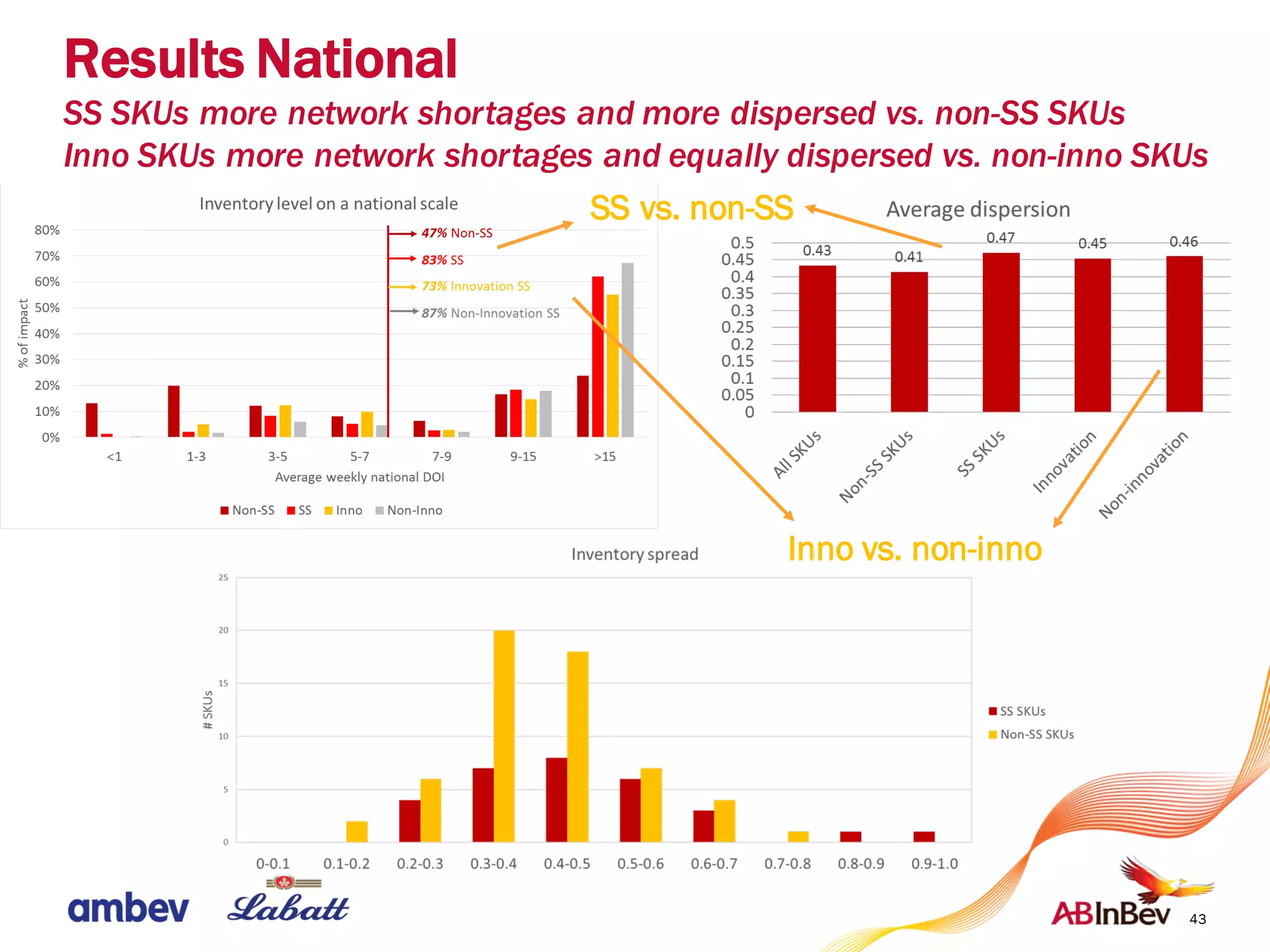

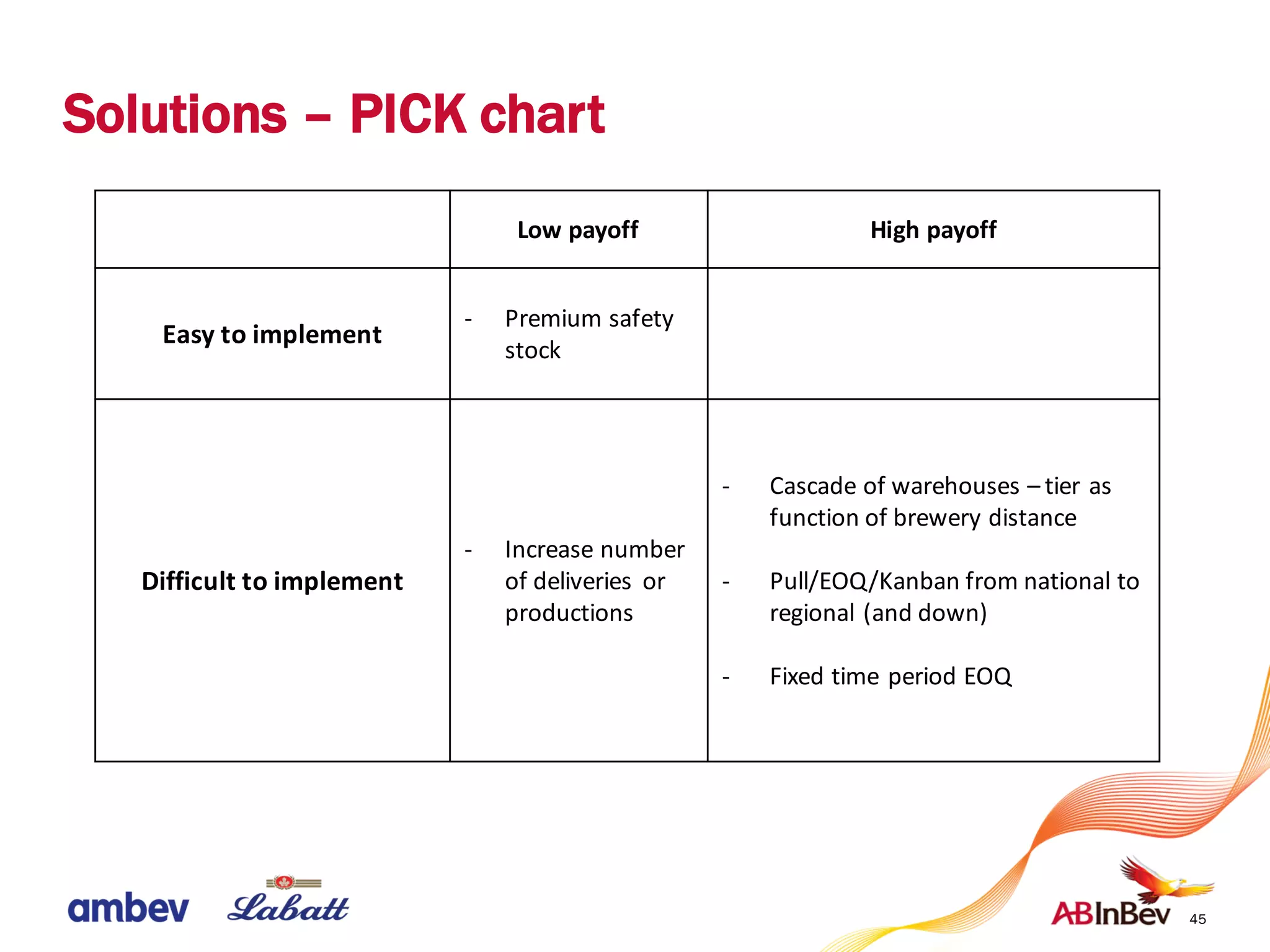

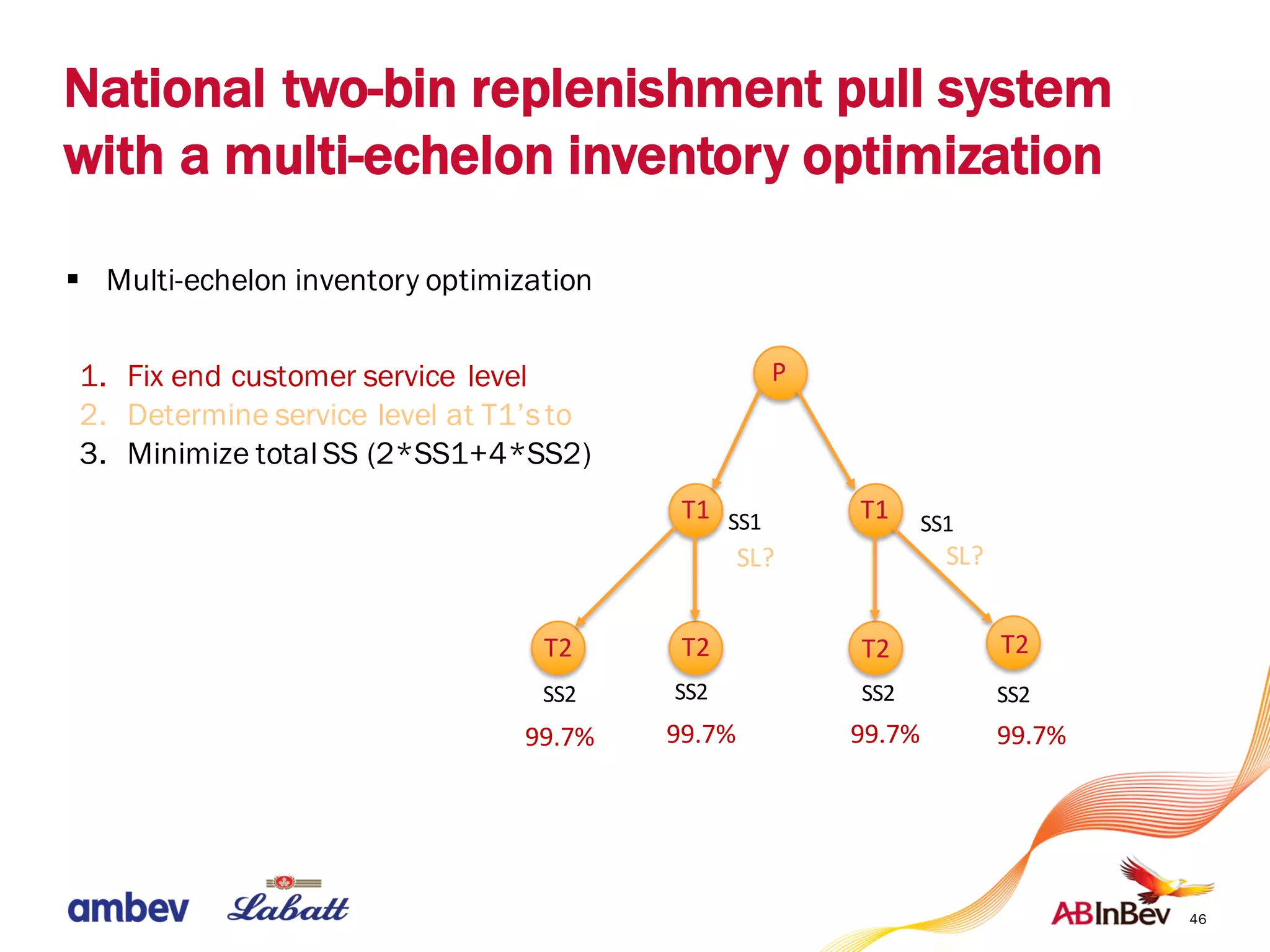

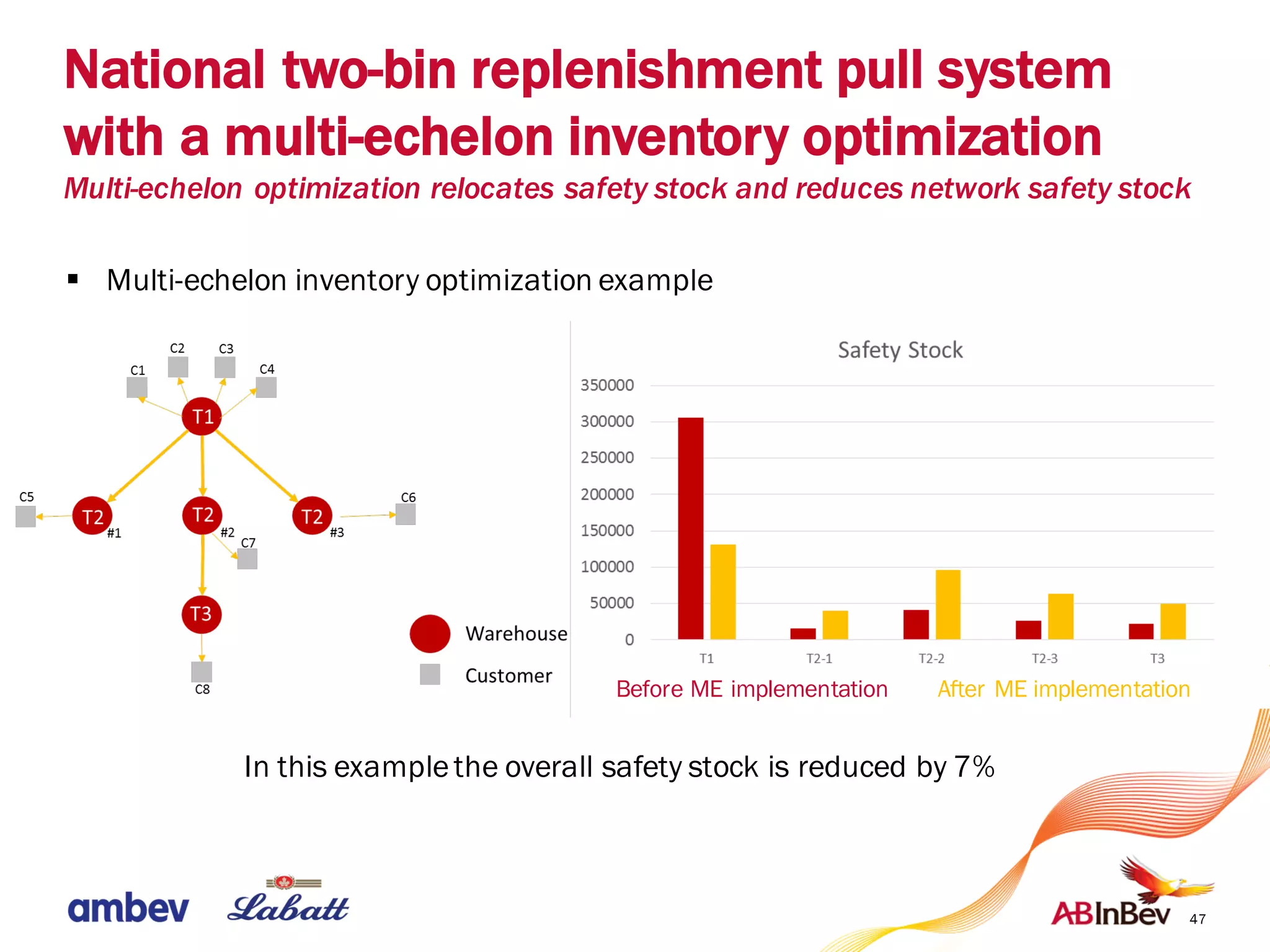

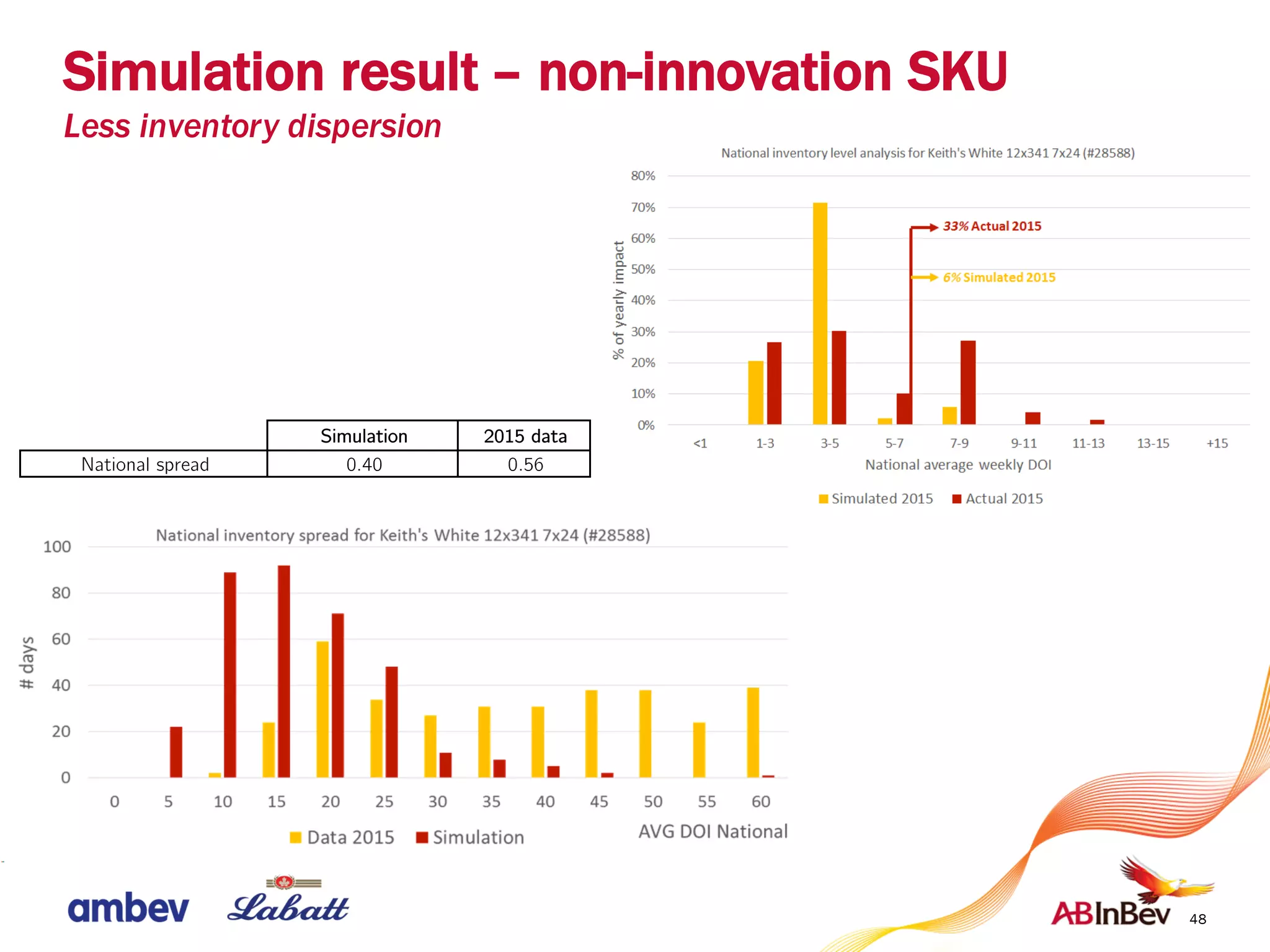

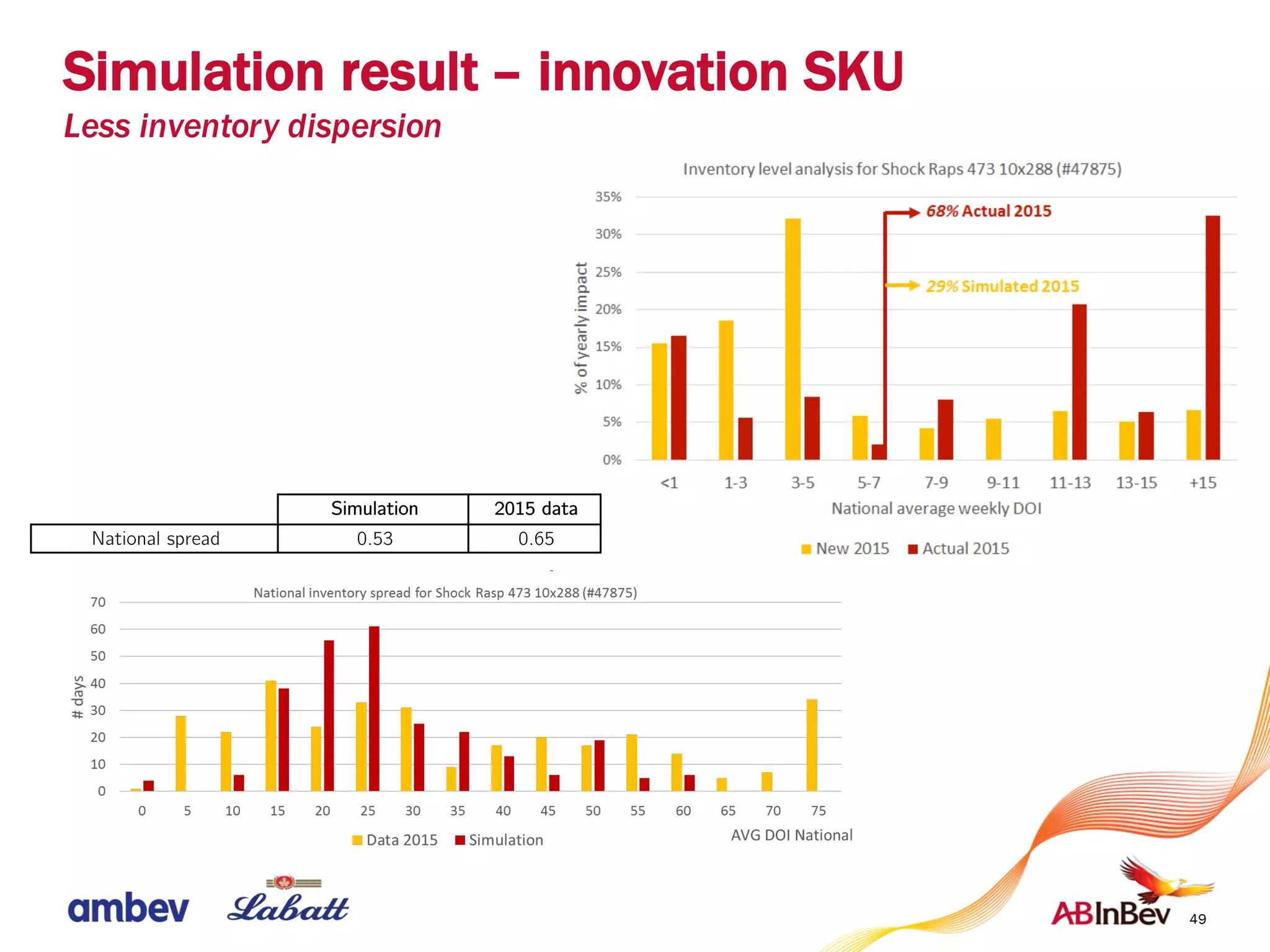

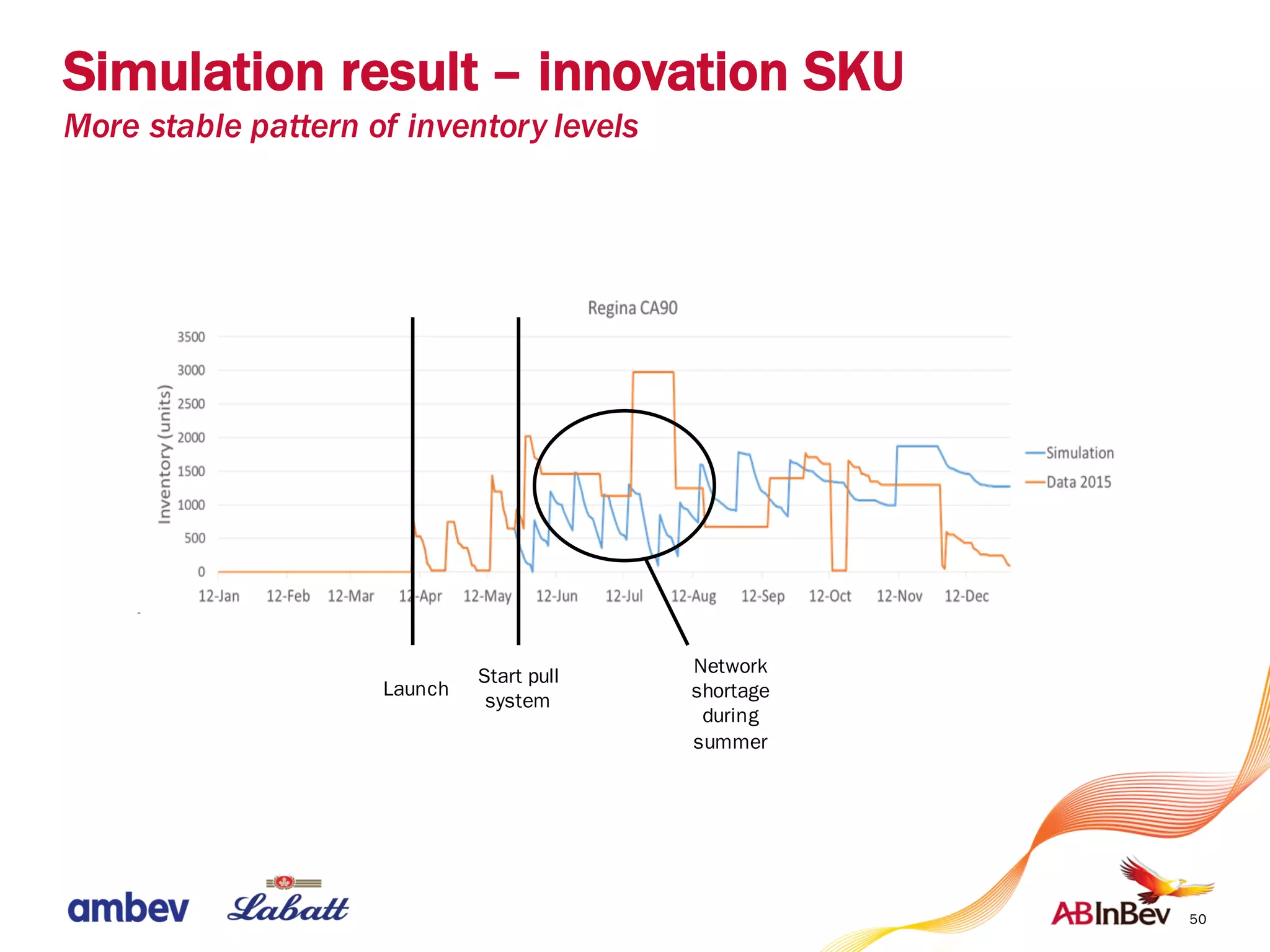

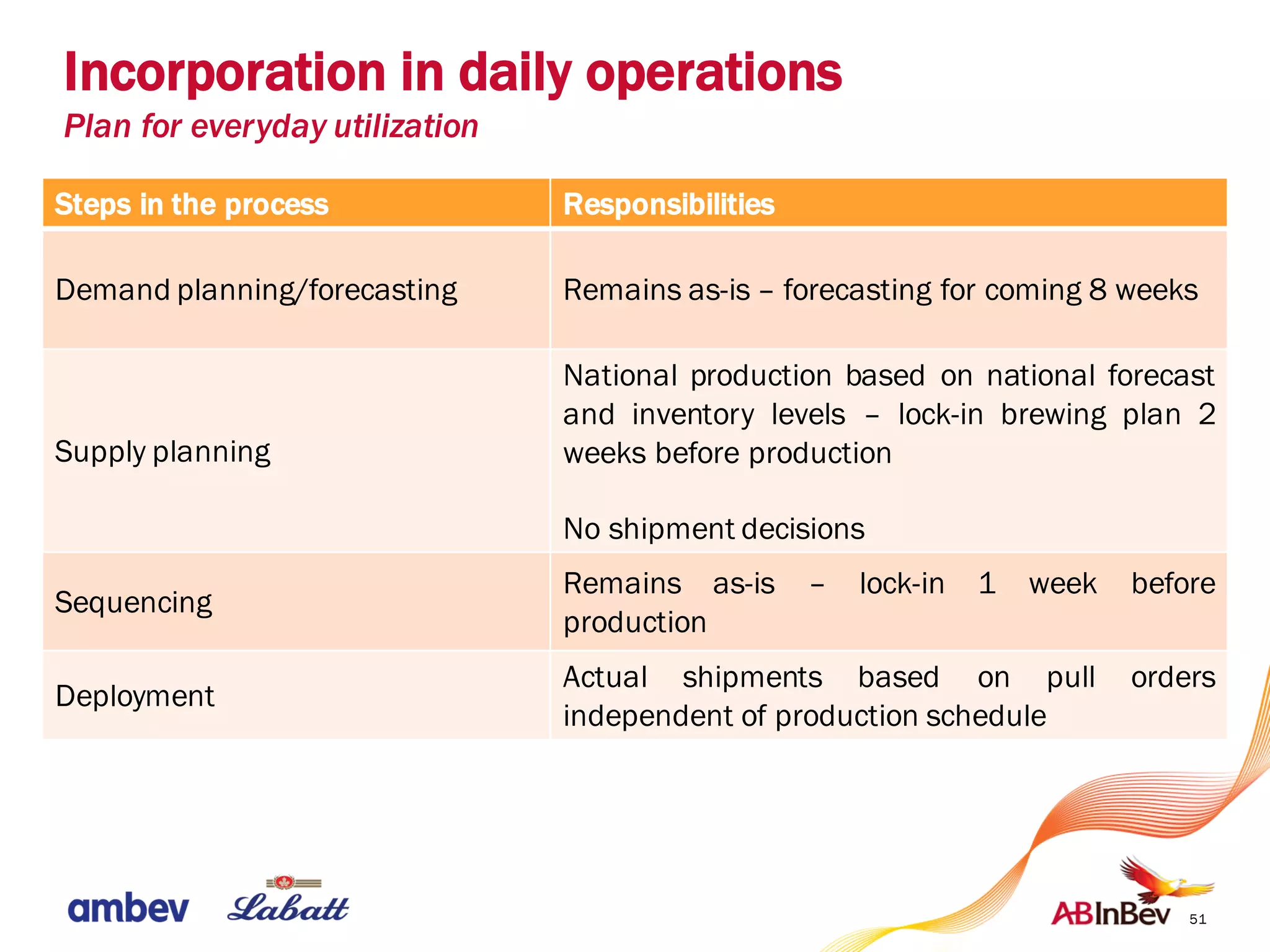

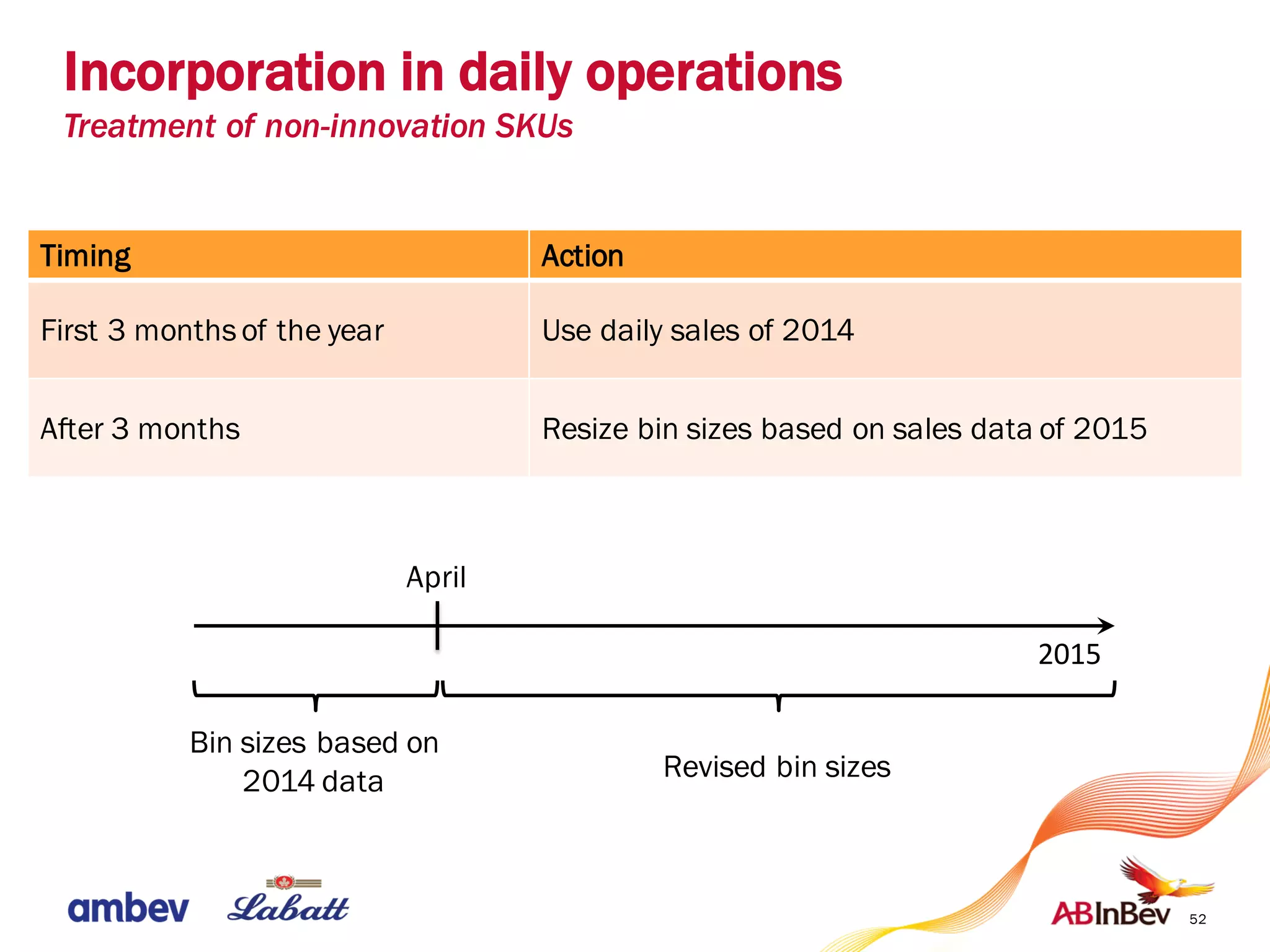

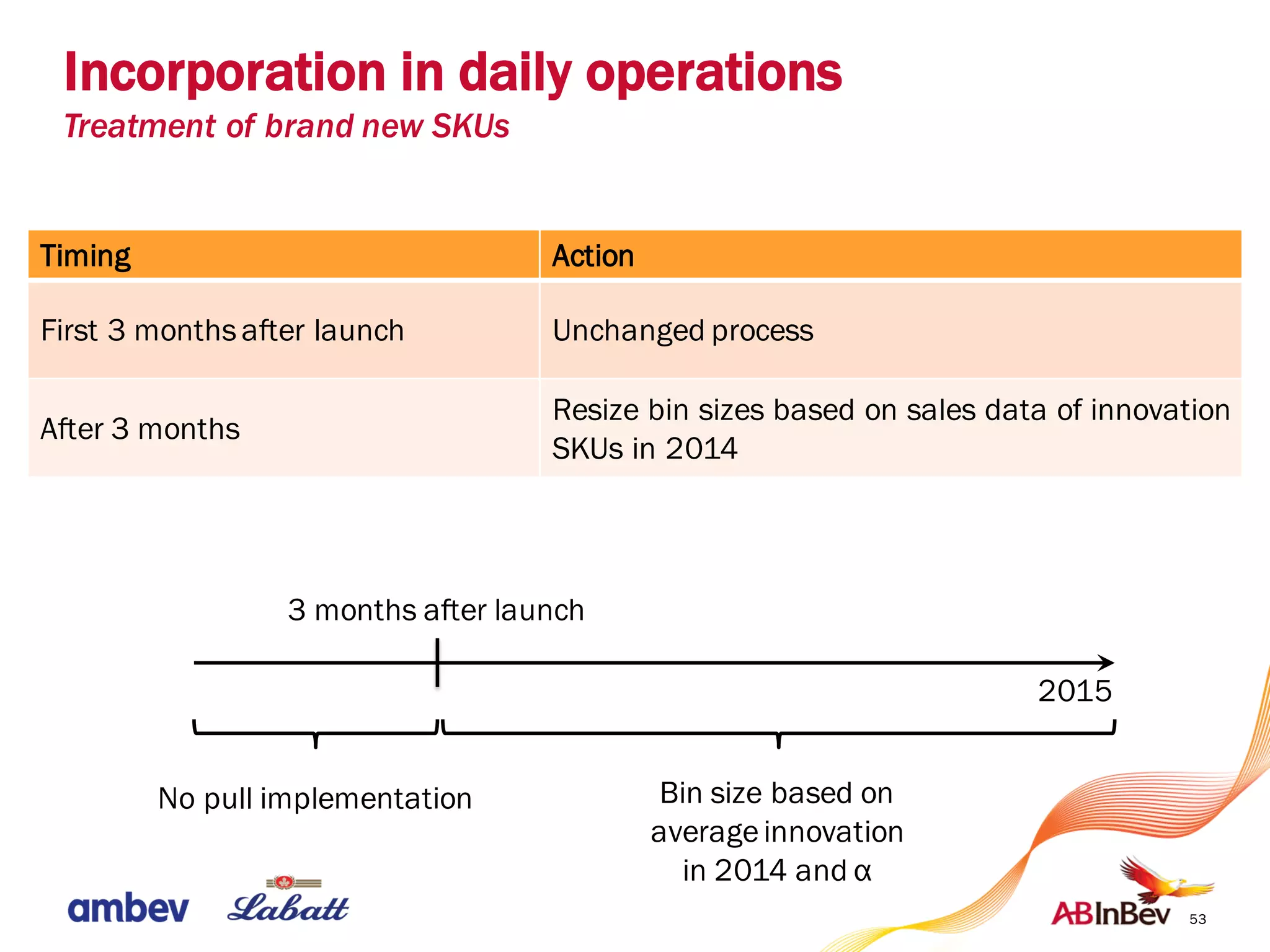

The document proposes a solution to improve service levels for single-source SKUs while maintaining supply chain losses. It involves implementing a national two-bin replenishment pull system with a multi-echelon inventory optimization model. Simulation results show the approach improves customer delivery performance and reduces inventory levels for non-innovation and innovation SKUs. Further refinement and testing of the model is recommended before full implementation.

![Service level within Labatt

5

§ Impact [hl] = demand [hl] – sales [hl]

§ Customer Delivery Performance = CDP [%]

§ CDP [%] =

"#$%&' [)*]

"#$%&' )* ,-%*.- [)*]](https://image.slidesharecdn.com/fbc569e2-1fd1-4e53-8392-cc881742ffd0-160703070209/75/Final_presentation_MatthiasVanKerkhove_SimonWostyn-5-2048.jpg)

![CDP [%] for different SKU types and regions

Innovation SKUs are the biggest hitters

9

1.4%

0.9%

1.0%

0.2%

*CDP =

"#$%&'

"#$%&',-%*.-

Non-SS SKUs](https://image.slidesharecdn.com/fbc569e2-1fd1-4e53-8392-cc881742ffd0-160703070209/75/Final_presentation_MatthiasVanKerkhove_SimonWostyn-9-2048.jpg)