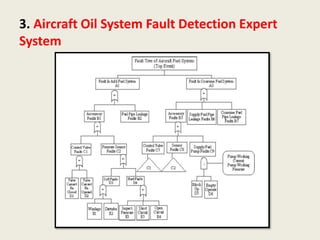

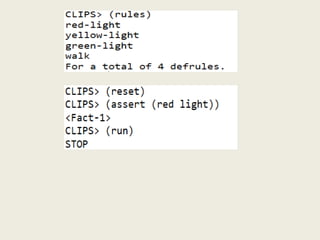

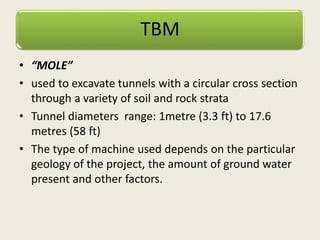

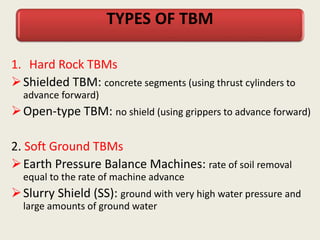

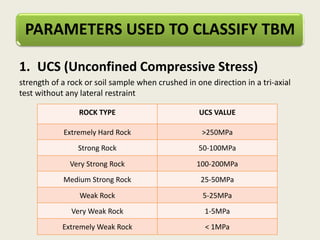

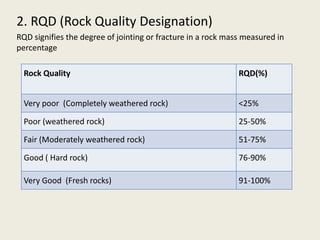

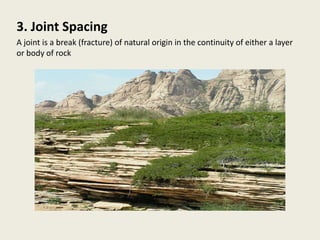

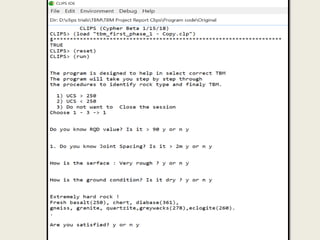

This document describes the development of an expert system for selecting tunnel boring machines (TBMs) using the CLIPS rule-based programming language. The expert system uses several parameters to classify TBMs, including unconfined compressive strength, rock quality designation, joint spacing, surface structure, and ground conditions. The document outlines the literature reviewed in developing the system, including existing expert systems for car failure diagnosis and eye disease diagnosis. It also notes a gap in prior work regarding TBM selection. The developed expert system is concluded to successfully select appropriate TBMs based on input parameters. Future work could involve adding more parameters to improve the system.

![REFERENCES

[1]. Ahmad T. Al-Taani (2007). An Expert System for Car Failure Diagnosis,Vol.1,No: 12, 750-753.

https://waset.org/publications/161/an-expert-system-for-car-failure-diagnosis

[2]. Assosiate Prof., Samy S. Abu Naser, Abu Zaiter A. Ola (2008). An Expert System for diagnosing Eye

Diseases using CLIPS,923-930

http://www.jatit.org/volumes/research-papers/Vol4No10/5Vol4No10.pdf

[3]. Hao Long (2015), Aircraft Oil system fault detection expert system,(Department of automatics

Beijing university, Beijing, China),196-199

https://download.atlantis-press.com/article/25842635.pdf

[4]. http://www.clipsrules.net/

[5]. NASA, Lyndon B. Johnson Space Center, CLIPS Basic Programming Guide,1991

[6]. CLIPS reference manual guide version 6.30

[7]. Joseph C. Giarratano CLIPS User Guide, version 6.30

[8]. Joseph Giarratano, Gary Riley (2004). Expert System: Principles and Programming,Fourth Edition.

[9]. Martin, Linda and Talor, Wendy, A Booklet About CLIPS Applications, NASA, Lyndon B. Johnson

Space Center, 1991

[10]. https://en.wikipedia.org/wiki/Tunnel_boring_machine

[11].https://theconstructor.org/geotechnical/rqd-rock-quality-designation-calculation/20536/

[12]. https://en.wikipedia.org/wiki/Joint_(geology)

[13]. https://en.wikipedia.org/wiki/Joint_(geology)#/media/File:PICT1709.JPG

[14].https://en.wikipedia.org/wiki/Joint_(geology)#/media/File:Joints_City_of_Rocks_NR.jpg](https://image.slidesharecdn.com/3rdsemproject-181224123530/85/Expert-system-for-Selection-of-TBM-using-ClIPS-25-320.jpg)