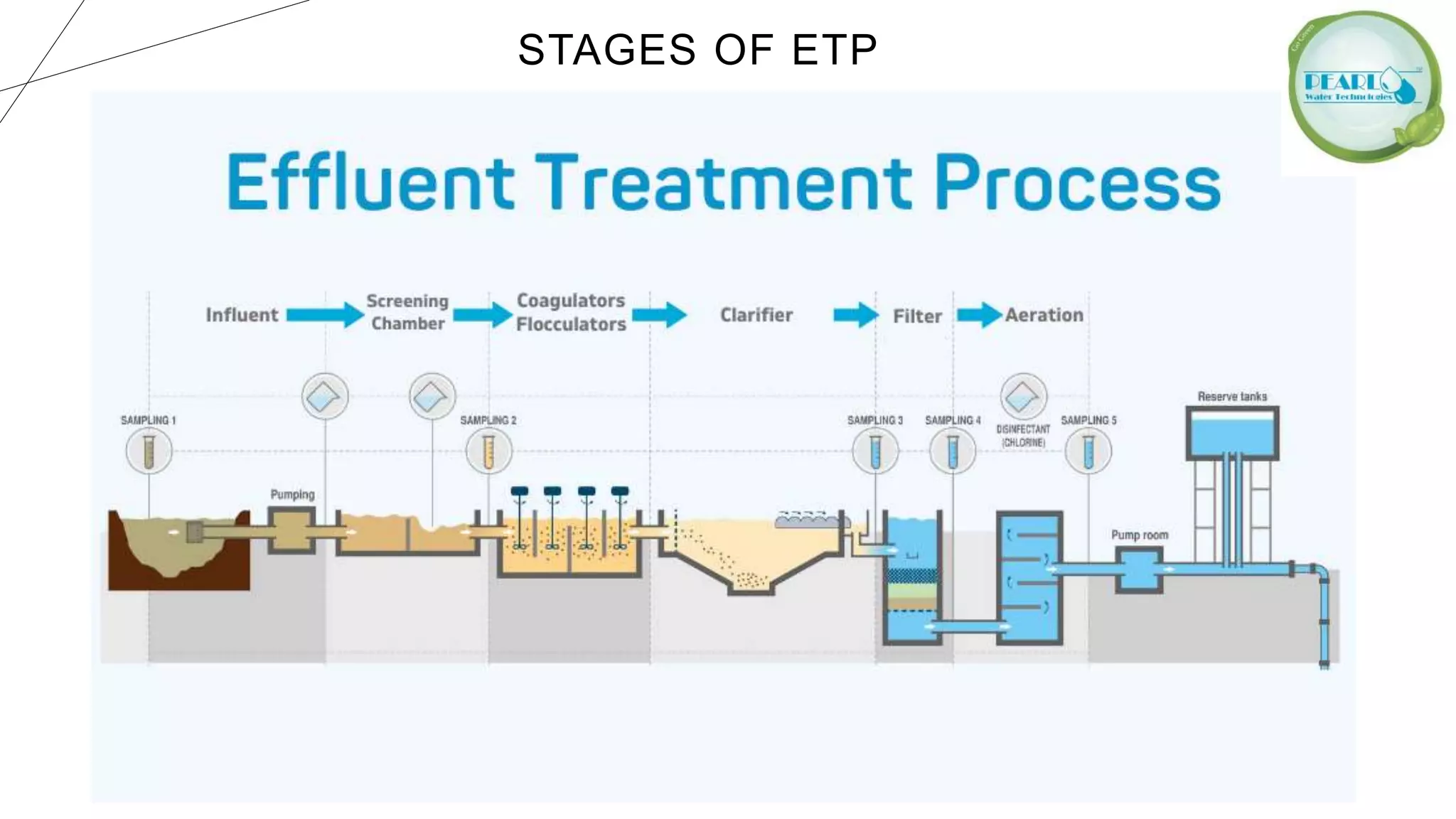

Pearl Water Technologies specializes in designing effluent treatment plants (ETPs) for industrial wastewater management, utilizing techniques such as evaporation, centrifuging, filtration, and incineration to ensure safe disposal or reuse. The ETP process involves multiple stages including screening, coagulation, sedimentation, filtration, and disinfection to purify water before distribution. The company offers a range of semi-automatic ETP systems tailored for different industrial needs, aiming to meet regulatory zero-discharge measures and enhance water recycling efficiency.