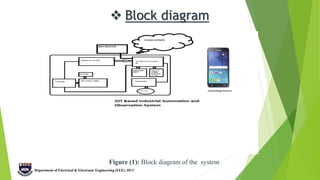

This document describes an IOT-based industrial automation observation system. The system monitors key industrial data like power consumption, temperature, and product counting. Sensors collect this data, which is sent to a cloud server and displayed on a website. This allows remote monitoring of industry performance and conditions. The system aims to increase efficiency while reducing safety risks. It provides a low-cost solution for industrial automation and monitoring through wireless communication and an open-source web server. Future work may include adding artificial intelligence and alternative power sources to the system.