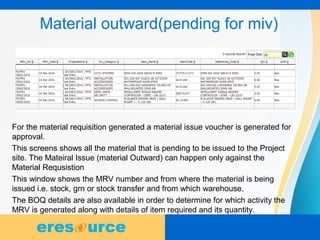

The document discusses inventory management and material tracking features in the NFRA Stores module. It allows users to manage inventories across central warehouses and project sites, track material flow with features like indents, goods receipt notes, material issues, and stock transfers. Reports provide visibility into store status, supply and demand, item ledgers, and material consumption. The system aims to help avoid material losses and ensure minimal stock discrepancies.