Environmental research purposal china.

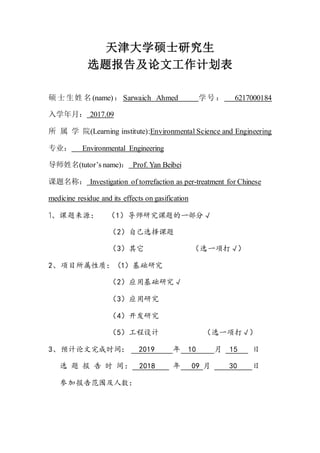

- 1. 天津大学硕士研究生 选题报告及论文工作计划表 硕 士 生姓 名 (name): Sarwaich Ahmed 学号 : 6217000184 入学年月: 2017.09 所 属 学 院(Learning institute):Environmental Science and Engineering 专业: Environmental Engineering 导师姓名(tutor’s name): Prof. Yan Beibei 课题名称: Investigation of torrefaction as per-treatment for Chinese medicine residue and its effects on gasification 1、课题来源: (1)导师研究课题的一部分√ (2)自己选择课题 (3)其它 (选一项打√) 2、项目所属性质:(1)基础研究 (2)应用基础研究√ (3)应用研究 (4)开发研究 (5)工程设计 (选一项打√) 3、预计论文完成时间: 2019 年 10 月 15 日 选 题 报 告 时 间: 2018 年 09 月 30 日 参加报告范围及人数:

- 2. 评议组成员姓名:陈冠益、刘佳、颜蓓蓓、昝文安 职 称:教授、教授、副教授 、教授级高工 1、拟选课题国内、外的研究动态、水平、存在问题,并附主要参考文献: The research trends, levels and existing problems in the domestic and external studies , and the main references In Recent years and current research, the contribution of biomass is considering as important factor for upcoming energy supply. [1]. Biomass is a renewable energy source that can be easily transformed into valuable energies such as electricity, liquid fuels, and gaseous fuels. Gasification is considered the main and important technology in the thermochemical technique of biomass valorization to heat and power, synthetic fuels and chemicals, as it converts biomass resourcefully and with high conversion rates. [2]. Though, Untreated biomass is not perfectly suitable for energy conversion applications. Because it is usually due to high moisture element which links to low energy content. Furthermore, its main biochemical and mineral compositions differ based on sort of biomass, time and location of cultivation. That’s why conversion of biomass is complex and logistics extra expensive. Hence, efforts are made to mature and upgrading processes which can easily converts biomass into a fuel by means of superior properties in relations with logistics and end-use. From most of the biomasses wood is considered as a best option due to its composition of contained ash and the fact that it can be raw substantial for another generation for biofuel production. The wood is mostly classified into two types hard wood and soft wood, which contains lignin, cellulose and hemicellulose, hardwoods lignin is measured more unstable to thermal treatment. [1,3]. However, World is challenging a major issue of hazardous gases, so it’s necessary to be mitigate greenhouse gases (GHSs) and also worlds energy consumption is going to increase day by day due to change in living standard, to overcome these problems renewable source biomass is a good solution. [4]. Nevertheless, Biomass for energy production is directly not much suitable because of some inherent disadvantages such as high moisture content, low bulk density, low heating value, and poor grindability. Torrefaction is considered as a pretreatment technique for upgrading the solid biomass fuel. Torrefaction method has two kinds, dry torrefaction and wet torrefaction. Dry Torrefaction (DT) is thermal treatment of biomass in an inert atmospheric pressure and temperatures inside the range of 200-300°C [5-7]. While, Wet torrefaction (WT) is treatment of hydrothermal media, or hot compressed water, at temperatures within 180-260°C [6-8]. At this temperature range hemicellulose is predictable to be the most changed polymer, shadowed by cellulose and lignin. Hemicelulose starts degrading between 200-380°C, with xylan being the most thermally unstable containing monomer at the low temperature side, followed by glucomannan [9]. Thermal degradation starts approximately at 200°C [10], and thermal devolatization

- 3. of cellulose starts approximately at 230 [11]. The result of torrefaction depends on temperature, time and nature of wood, in count torrefaction in combination with a densification step is a promising technology for promotion, the biomass becomes more coal alike, has higher energy density, lower O/C and H/C ratios, it becomes more hydrophobic, extra resilient against biological degradation and more rigid. So, toreefaction leads to benefits in transportation, handling and storage [12-15]. During thermal degradation, some mineral matter may affect the behavior of biomass components, altering the distribution and chemical specification of the pyrolysis products. The mineral matter content of raw biomass may vary from less than 1 by wt % to more than 25 wt% depending the type of biomass, mainly consisting of Al, Ca, Fe, K, Mg, Na and Si with similar amounts of S, P, Cl and Mn [16]. Among above metals potassium appears to have the greatest influence on thermal degradation [17]. These torrefaction studies, however, did not analyze the effect of potassium addition on the composition and yield of the condensable species. Increasing potassium content may enhance lignin derivative yield during pyrolysis [18-19]. After torrefaction the torrefied material is prepared for gasification and it is typically defined as a partial oxidation of the fuel, which is treated in sub stoichiometric environments, leading to the production of syngas and a series of byproducts. The potential benefits of gasification over traditional combustion of solid waste are mainly related to the advantages of handling (and burning) a gas versus a solid waste [20]. In adding gasification presents a high-level efficiency and the produced syngas can be used in different application, such as generation of electricity, fuels and chemicals, only biomass is acting as a main renewable source for gasification [21-22]. Tar formation is one of main task in present thermal gasification technologies, and mainly during biomass gasification. Tar is a condensable carbon-based product composites mostly by olefins, phenolics, mono and poly nuclear aromatics, heterocyclic aldehydes and alkyl derivates of aromatics [2]. Tars formed during biomass gasification may condensed tend to polymerize into more complex structures, which represent a serious drawback for the use of producer gas, foe both CHP and synthesis of biofuels or other chemicals. Condensed tars, particularly when mixed with char and fly ash particles, cause clogging and fouling in downstream boilers, gas cleaning systems and catalytic reactors and deactivate downstream catalysts. These technical issues related to tar formation typically lead to high operation and maintenance cost in commercial scale facilities, removal of tars from the gas stream after gasification, although necessary to achieve the gas purity required by its downstream processing, increase operation costs and reduces the thermal efficiency of the gasification unit, since tars retain a significant fraction of the energy of biomass fuel. The extensive research available in literature related to tar formation has mainly focused on experimental characterization of tars produced from biomass pyrolysis and gasification under various conditions [23-30]. The use of catalysts and additives to reduce tar formation in biomass gasification has also been extensively investigated [2, 31,32]. References

- 4. 1. M. Asmadi,H. Kawamoto, S. Saka,Characteristicsof softwood and hardwood pyrolysisin an ampoule reactor, J. Anal. Appl. Pyrolysis124 (2017) 523e535, 2. http://dx.doi.org/10.1016/j.jaap.2017.01.029.MilneT, Evans R. Biomass gasifier “Tars”:their nature, formation,and conversion.National Renewable Energy Laboratory; 1998e25357. NREL/TP-570. 3. M. Poletto. Assessment of the thermal behavior of lignins fromsoftwood and hard wood species,Maderas Cienc.Y Tecnol. 19 (2017) 63e74, http://dx.doi.org/10.4067/S071 8-221X2017005000006. 4. D. Da Silva Perez, C. Dupont, A. Guillemain,S.Jacob, F. Labalette, S. Briand,J.M. Commandre, Characterisation of the most representative agricultural and forestry biomasses in Francefor gasification,WasteBiomassValorization 6 (4) (2015) 515–526 https://doi.org/10.1007/s12649-015-9374-3. 5. W.-H. Chen, W.-Y. Cheng, K.-M. Lu, and Y.-P. Huang, "An evaluation on improvement of pulverized biomass property for solid fuel through torrefaction," Applied Energy, vol.88, pp. 3636-3644,2011. 6. D. Tapasvi,R.Khalil,Ø.Skreiberg, K.-Q. Tran, and M. Grønli,"Torrefaction of Norwegian Birch and Spruce: An Experimental Study Using Macro-TGA," Energy & Fuels, vol. 26, pp. 5232-5240, 2012. 7. M. J. C. van der Stelt, H. Gerhauser, J. H. A. Kiel,and K. J. Ptasinski,"Biomassupgradingby torrefaction for the production of biofuels:A review," Biomass and Bioenergy, vol.35, pp. 3748-3762,2011. 8. Q.-V. Bach, K.-Q. Tran, R. A. Khalil,Ø.Skreiberg, and G. Seisenbaeva, "ComparativeAssessment of Wet Torrefaction," Energy & Fuels, vol. 27, pp. 6743-6753,2013. 9. K. Werner, L. Pommer, M. Brostr€om, Thermal decomposition of hemicelluloses,J.Anal.Appl. Pyrolysis110 (2014) 130e137, http://dx.doi.org/ 10.1016/j.jaap.2014.08.013. 10. B. Joffres, D. Laurenti, N. Charon,A. Daudin,A. Quignard,C. Geantet, Thermochemical conversion of lignin for fuels and chemicals:a review, Oil Gas Sci.Technol.e Revue d’IFP Energies Nouvelles 68 (2013) 753e763, http://dx.doi.org/10.2516/ogst/2013132. 11. V. Pasangulapati,Devolatilization Characteristicsof Cellulose,Hemicellulose,Lignin and the Selected Biomass duringThermochemical Gasification:Experiment and ModelingStudies, Oklahoma State University,2012.http://gradworks.umi.com/15/13/1513363.html. (Accessed 29 September 2015). 12. G. Xue, M. Kwapinska,W.Kwapinski,K.M. Czajka,J. Kennedy, J.J. Leahy, Impactof torrefaction on properties of Miscanthus_giganteus relevantto gasification,Fuel 121 (2014) 189e197, http://dx.doi.org/10.1016/j.fuel.2013.12.022. 13. C. Couhert, S. Salvador,J.-M. Commandr_e, Impactof torrefaction on syngas production from wood, Fuel 88 (2009) 2286e2290, http://dx.doi.org/10.1016/j.fuel.2009.05.003. 14. E.M. Fisher,C. Dupont, L.I. Darvell,J.-M. Commandr_e, A. Saddawi,J.M. Jones, M. Grateau, T. Nocquet, S. Salvador,Combustion and gasification characteristicsof chars fromrawand torrefied biomass,Bioresour.Technol.119 (2012)157e165, http://dx.doi.org/10.1016/j.biortech.2012.05.109. 15. G.-A. Tsalidis,Y. Joshi,G. Korevaar,W. de Jong, Life cycleassessmentof directco-firingof torrefied and/or pelletised woody biomass with coal in The Netherlands, J. Clean.Prod. 81 (2014) 168e177, http://dx.doi.org/10.1016/j.jclepro.2014.06.049.

- 5. 16. K. Raveendran, A. Ganesh, K.C. Khilar,Influenceof mineral matter on biomass pyrolysis characteristics,Fuel 74 (1995) 1812–1822,http://dx.doi.org/10.1016/0016-2361(95)80013-8. 17. E. Jakab,Analytical Techniques as a Tool to Understand the Reaction Mechanism,in: E.A. Pandey, T. Bhaskar,M. Stocker, R.K. Sukumaran (Eds.), Recent Adv. Thermochem. Convers. Biomass,1stEditio,Elsevier,2015, pp. 73–106, , http://dx.doi.org/10.1016/B978-0-444-63289-0.00003-X. 18. R. Mahadevan,S. Adhikari,R. Shakya,K. Wang, D. Dayton, M. Lehrich, S.E. Taylor,Effect of alkali and alkalineearth metals on in-situ catalytic fastpyrolysisof lignocellulosicbiomass:a microreactor study, Energy Fuel 30 (2016) 30453056,http://dx.doi.org /10.1021 / acs. energyfuels.5b02984. 19. I.Y. Eom, J.Y. Kim, T.S. Kim, S.M. Lee, D. Choi, I.G. Choi, J.W. Choi,Effect of essential inorganic metals on primary thermal degradation of lignocellulosic biomass,Bioresour.Technol.104 (2012) 687–694, http:// dx.doi.org/ 10.1016/j. 20. Arena U. Process and technological aspects of municipal solid wastegasification:a review. Waste Manag 2012; 32:625–39. http://dx.doi.org/10.1016/j.wasman.2011.09.025. 21. Alimuddin Z, Zainal B,Lahijani P,Mohammadi M, Rahman A. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: a review. Renew Sustain Energy Rev 2010; 14:2852–62.http://dx.doi.org/10.1016/j.rser.2010.07.026. 22. Ahmad AA, Zawawi NA, KasimFH, InayatA, Khasri A. Assessingthegasification performanceof biomass:a review on biomass gasification process conditions,optimization and economic evaluation.Renew Sustain Energy Rev2016; 53:1333–47. http://dx.doi.org/10.1016/j.rser.2015.09.030. 23. MilneT, Evans R. Biomass gasifier “Tars”:their nature, formation, and conversion.National Renewable Energy Laboratory; 1998e25357.NREL/TP-570. 24. Rabou LPLM, Zwart RWR, Vreugdenhil BJ, Bos L. Tar in biomass producer gas,the Energy Research Centre of the Netherlands (ECN) experience: an enduring challenge.Energy Fuels 2009;23(12):6189e98. 25. Kitzler H, Pfeifer C, Hofbauer H. Pressurized gasification of woody biomassdvariation of parameter. Fuel Process Technol 2011;92(5):908e14. 26. Mayerhofer M, Mitsakis P,Meng X, de Jong W, Spliethoff H, Gaderer M. Influenceof pressure, temperature and steam on tar and gas in allothermal fluidized bed gasification.Fuel 2012;99(0):204e9. 27. Meng X, de Jong W, Fu N, Verkooijen AHM. Biomass gasification in a 100 kWth steam-oxygen blown circulating fluidized bed gasifier:effects of operational conditionson productgas distribution and tar formation.Biomass Bioenergy 2011;35(7):2910e24. 28. Qin Y-H, Feng J, Li W-Y. Formation of tar and its characterization duringairesteamgasi fication of sawdustin a fluidized bed reactor. Fuel 2010;89(7):1344e7. 29. Yu Q, Brage C, Chen G, SjöströmK. Temperature impacton the formation of tar from biomass pyrolysisin a free-fall reactor.J Anal Appl Pyrol 1997;40e41:481e9. 30. Hernández JJ, Ballesteros R,Aranda G. Characterisation of tars from biomass gasification:effect of the operating conditions.Energy 2013;50(1):333e42. 31. Narváez I, Orío A, Aznar MP, Corella J. Biomass gasification with air in an atmospheric bubbling fluidized bed. Effect of six operational variables on the quality of the produced rawgas.Indus Eng Chem Res 1996;35(7):2110e20.

- 6. 32. Asadullah M,Miyazawa T, Ito S, Kunimori K, Yamada M, Tomishige Keiichi.Catalystdevelopment for the gasification of biomassin the dual-bed gasifier.Appl Catal A Gen 2003;255(2):169e80. 2、 课题拟解决的主要技术问题, 在理论和应用方面的意义, 完成课题的条件 (包 括个人业务水平、教研室或学科组的技术、设备条件)和拟采取的技术措施和办 法: 2 Research significance, Innovation, work plan a) To perform Torrefaction or catalytic torrefaction process, catalytic torrefaction don’t have a lot of work we can use some good catalyst to see the effects of catalyst on tar formation, it may be innovative. b) Investigate the changes in feedstock before and after torrefaction, there may be some innovations. c) To find out the ultimate analysis (Carbon, Hydrogen, Oxygen, Nitrogen Sulfur etc.) d) To find out proximate analysis (Moisture, Volatiles, Fixed carbon, Ash, Lower heating value LHV) e) Purpose of torrefaction is to get best gasification products and reduces emission of gases and control pollution f) Active Analysis of torrefied biomass gasification specially syngas production and tar content. g) Due to tar formation there are many drawbacks such as slagging, fouling in downstream boilers, gas cleaning systems and catalytic reactors and deactivate the downstream catalysts, we can compare either torrefaction has good impact on tar formation or not during gasification. Geographical structure 3、 课题进展计划(包括各阶段计划完成的内容和所需的时间等)。 3. Project progress plan (including the content and time required for each phase plan).

- 7. Materials and method Biomass feedstock maybe we use is Chinese medicine residue, and medicine residue can be obtained from any of hospital or medicine universities.TG and DTG and FT-IR (Fourier transform infrared) spectroscopy will be used to investigate the change in biomass feedstock after torrefaction, TGA-FTIR instrument is composed of a thermogravimetric analyzer (TGA) and and DTG Differntial thermogravimetric will be used, Tube furnace and fixed bed gasifier will be used for torrefaction and gasification. Experimental Procedure Torrefaction process: First of all, physical and chemical adsorption and desorption/ ultimate and proximate analysis will be held by GC, GC-MS, PY-GC-MS, TG, FTIR. GC-MS: This will be used to combine the features of gas chromatography and mass spectroscopy to identify different substances within a test sample. PY-GC-MS: Pyrolysis-gas chromatography-mass spectroscopy is a method of chemical analysis in which the sample is heated to decomposition to produce smaller molecules that are separated by gas chromatography and detected using mass spectroscopy. TG-Thermal Gravity: TG it’s a method in which we will measure the mass of sample over time as the temperature changes, this measurement provides information about physical phenomena as well as chemical phenomena. DTG-Differential Thermogravimetric: DTG is also a type of thermal analysis in which the rate of material weight changes upon heating is played against temperature and used to simplify reading the weight versus temperature thermogram peaks which occur together, It will be very useful to record the first derivative of TG/TGA curve DTG also because it makes noticing small features/boulders on the curve much easier. Fourier Infrared (FTIR) spectrometer: For the analysis of evolved gases. During the heating operation of sample, the evolving volatile products are carried out of the furnace directly into a gas cell where the gases are analyzed by FT-IR. The FT-IR spectrometer can obtain spectra every forty seconds to determine quantitatively the evolution rate and composition of oxidation gaseous product Reactor for torrefaction process will be used according to the availability in laboratory. Furthermore, Biomass Samples can be dried in an oven at standard temperatures between 80-100°C for some hours, and then it will be powdered and sieved by any mesh screen, particle size will be in between 0.4-0.6mm and will be collected for subsequent torrefaction and analysis, and further will be torrefied in tube furnace. samples can be dried in an oven at standard temperatures between 80-100°C for some hours, and then it will be powdered and sieved by any mesh screen and will be collected for subsequent torrefaction and analysis In this study we will take four different temperatures and times for torrefaction and compare results, temperature range will be in between 200-300°C and time will be in between 15-60minutes, Bed Materials can be used such as CaO, or alkali metals

- 8. and CaO can be prepare from egg shell or other materials. Diagrammatically view is given bellow, After that the torrefied materials will be usedfor gasification process to get better products and reduce the drawbacks during gasification process we will use fixed bed gasifier. Work plan Description Required time Literature review 2018.10-2019.02 Perform experiments 2019.03-2019.06 Data analysis 2019.07-2019.08 Writing Papers/Thesis 2019.09-2018.11 4、 导师对硕士生选题报告的评语(硕士生对国内外文献、动态、水平是否了解 清楚,所选课题是否适当、正确,预期目标能否达到,理论和实际应用的价 值如何、路线和措施是否具体可行等): Advisor for master's topic selection report reviews (master of literature at home and abroad, dynamic, levels are made sure that the selected topic whether appropriate, accurate and can achieve the anticipated goals, and how the value of theory and practical application, whether feasible routes and measures, etc.) : 导师签字: 年 月 日

- 9. 5、选题报告会评议组意见: 组长 (签字) : 年 月 日 6、学院审查意见: 学院 (公章) 主管院长 (签字) : 年 月 日 注:1、此表一式三份(导师、学院、硕士生本人各一份)。硕士生应在第三学 期末举行的选题报告会之前填写此表, 经导师和评议组负责人签署意见后报所在 学院审核。 2、答辩申请时,硕士生应向学院和学校提交此表。