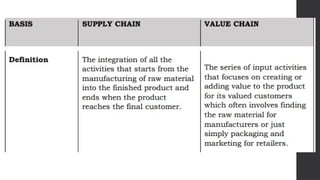

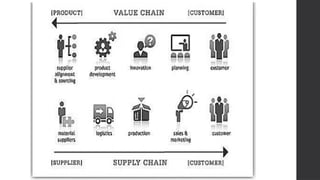

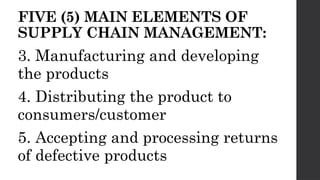

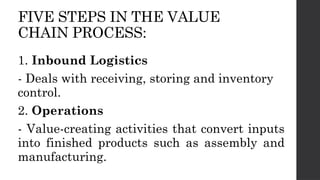

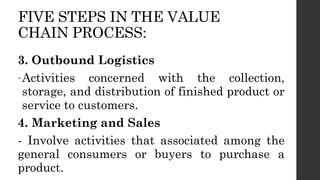

The document outlines the main elements of supply chain management, including product design, raw material procurement, manufacturing, distribution, and return processing, with the aim of reducing costs and maximizing customer satisfaction. It also describes the value chain process, which consists of inbound logistics, operations, outbound logistics, marketing and sales, and service, aimed at enhancing performance and customer value. Both supply and value chains ultimately focus on efficiently delivering products to consumers while maintaining satisfaction.