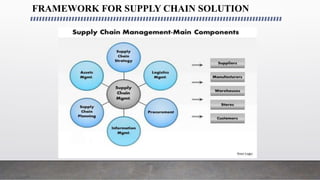

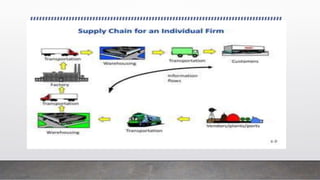

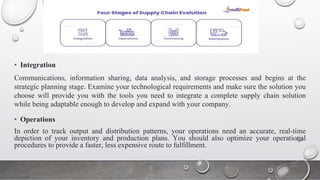

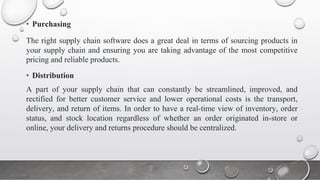

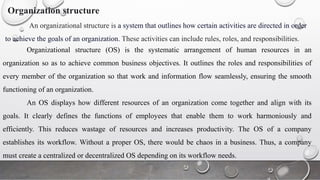

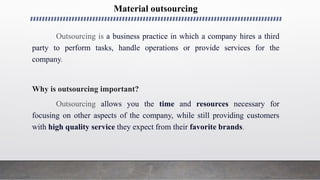

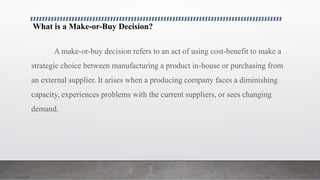

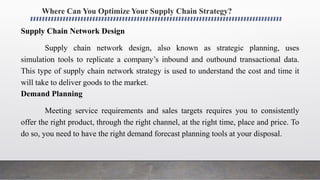

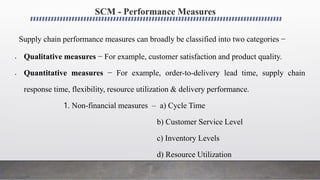

The document discusses supply chain management. It defines supply chain management as the process of delivering a product from raw material to the consumer. It notes that supply chain management includes planning, sourcing, production, delivery, and handling customer complaints. It also discusses the importance of supply chain management in improving customer satisfaction and business performance. Finally, it outlines the key components of an effective supply chain management process.

![Why is supply chain management important?

Focusing supply chain management on strategic activities can have a

positive impact that resounds throughout the business. There are two

core areas:

supply chain processes and

procedures - can contribute to business results

customer happiness and Return On Investment [ROI].

• Happy customer = Happy business = Higher performance](https://image.slidesharecdn.com/logisticsandsupplychainmanagement-240408160644-29083d99/85/LOGISTICS-AND-SUPPLY-CHAIN-MANAGEMENT-pptx-3-320.jpg)