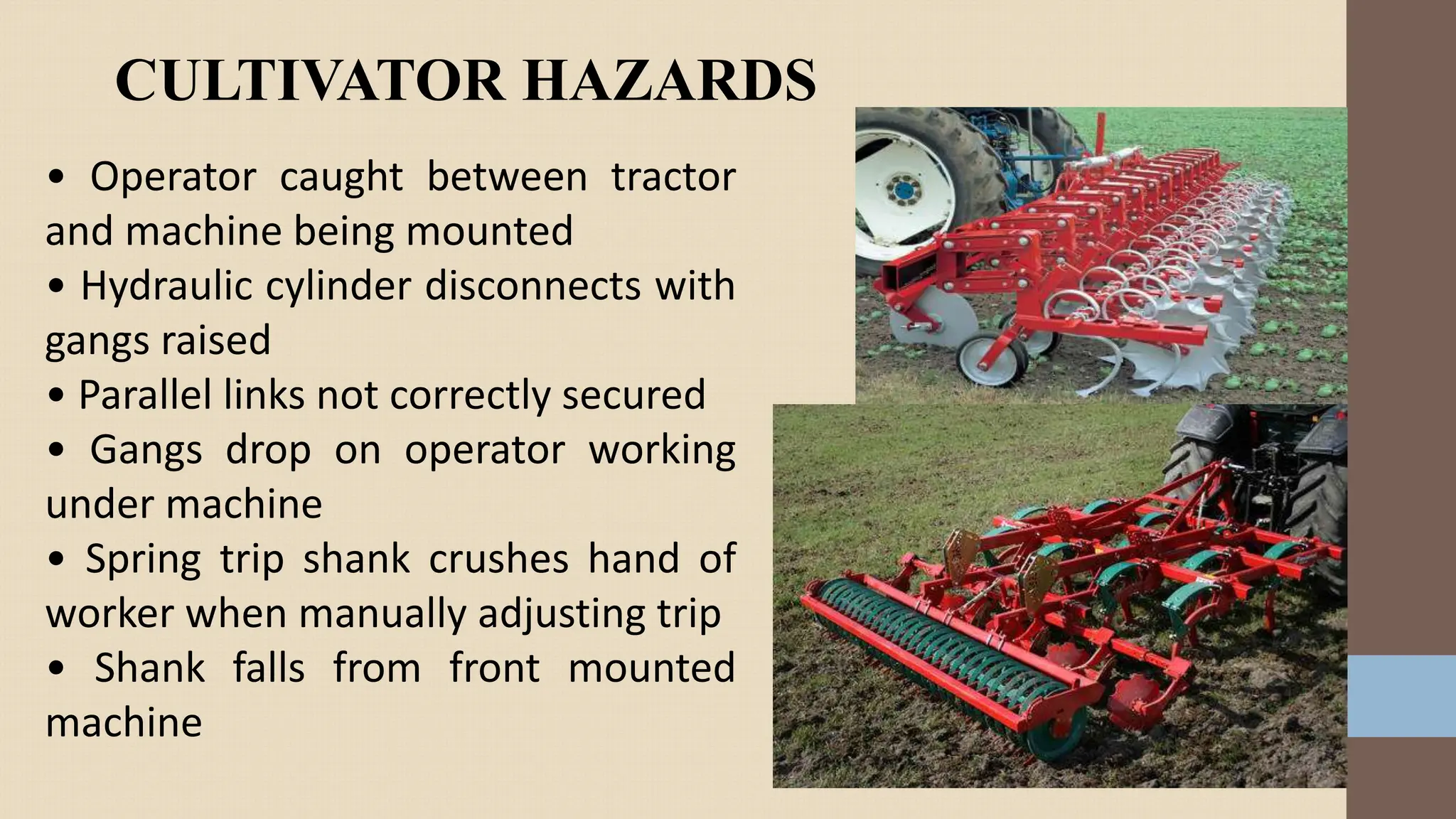

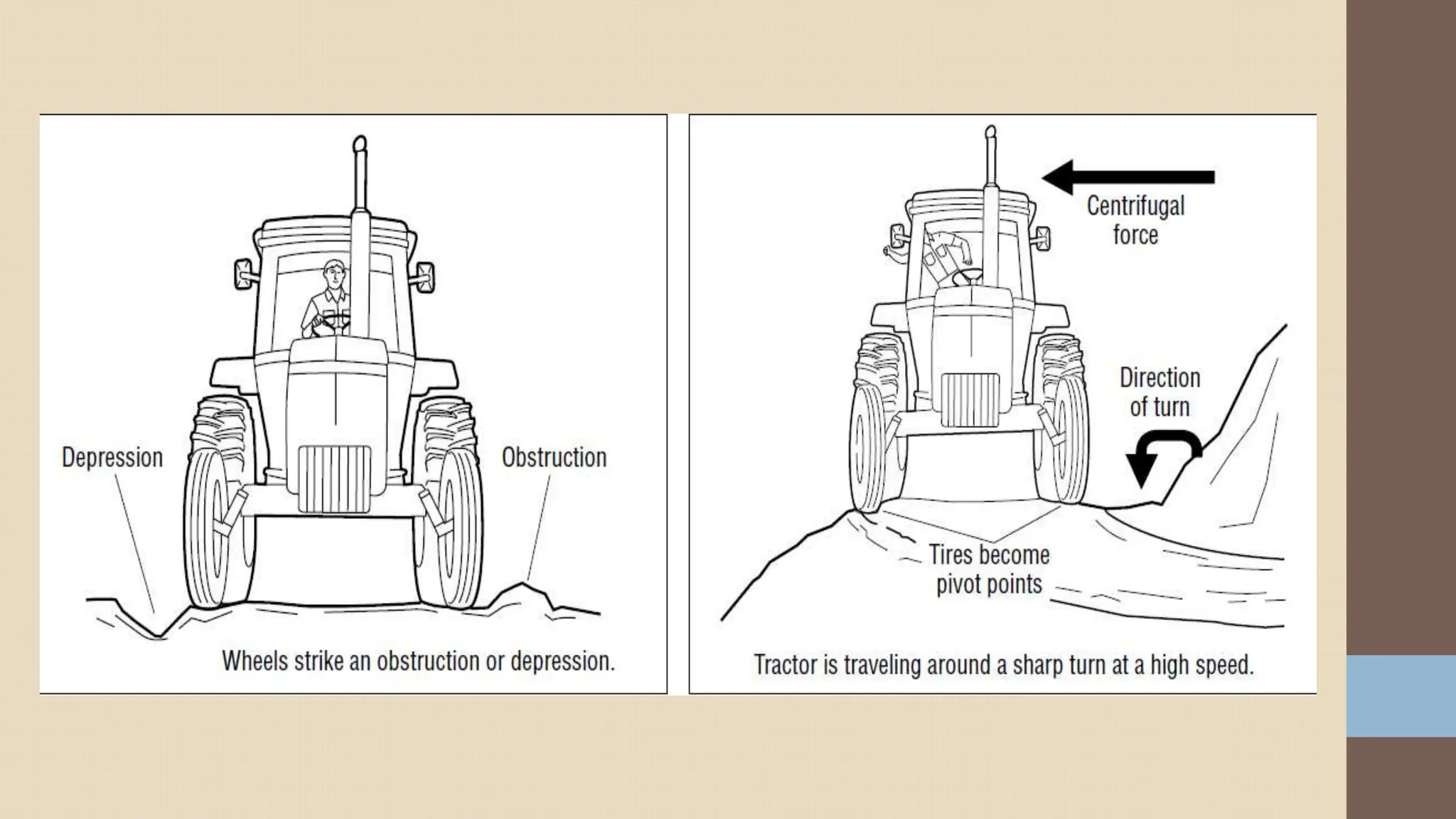

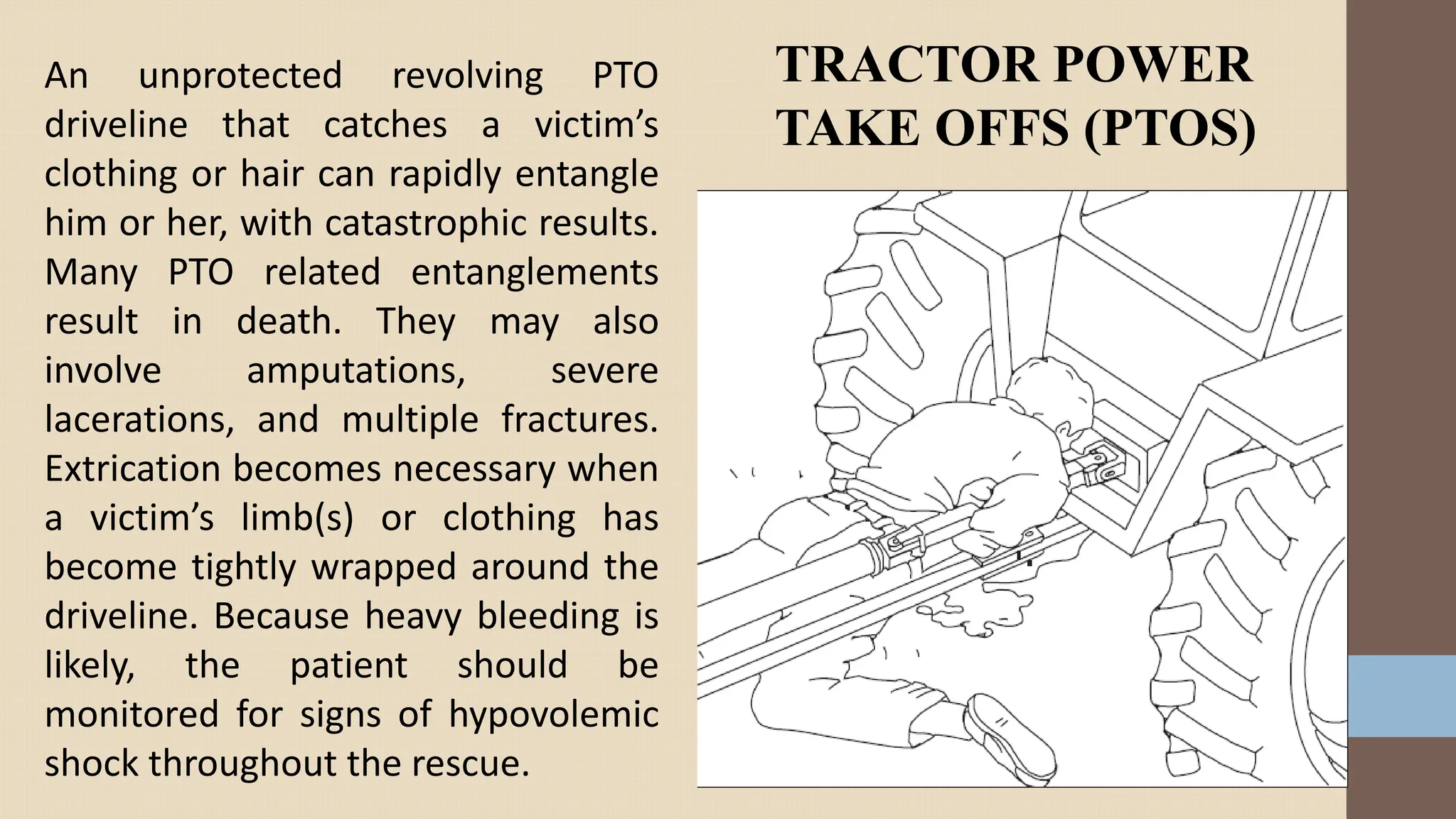

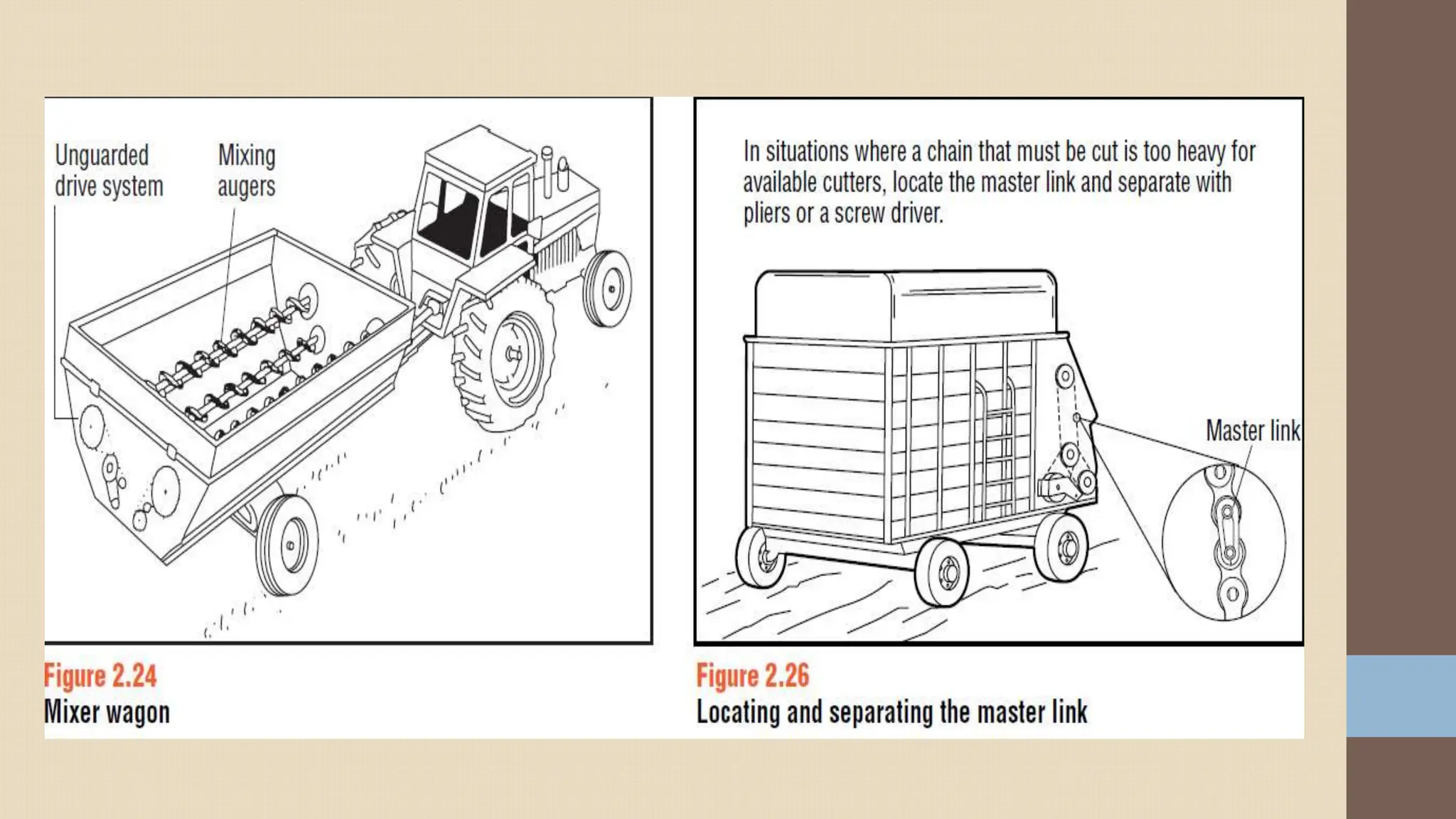

The document outlines emergency procedures and safety standards regarding farm machinery operations, highlighting common causes of accidents such as improper use of machinery, communication issues, and operator fatigue. It emphasizes the importance of safety equipment, proper training, and precautions to prevent injuries, particularly from hazardous situations like tractor rollovers and PTO entanglements. Specific guidelines are provided for operating machinery safely and the steps to take in case of an emergency, including how to stabilize and rescue victims from accidents.